Operating Instructions

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Series H Hand Crank Hose Reels

Low, Medium and High Pressure Model Numbers:

H16000

H28000

H18000 M

H28000 M

H18000

H28005

H18005 M

H29000 M

H18005

H29000

H18006 M

H16000 H

H19000

H29005

H19000 M

H26000 H

H26000

H16000 M

H26000 M

H28000 H

Read this manual carefully before installing, operating

or servicing this equipment.

IMPORTANT

• Ensure that reel is properly installed before connecting input and

output hoses.

• Bleed fluid/gas pressure from system before servicing reel.

• Before connecting reel to supply line, ensure that pressure does

not exceed maximum working pressure rating of reel.

• Remember, even low pressure is very dangerous and can cause

personal injury or death.

• Be aware of machinery and personnel in work area.

• If a leak occurs in the hose or reel, remove system pressure

immediately.

• A high tension spring assembly is contained within the reel.

Exercise extreme caution.

• Pull hose from reel by grasping the hose itself, not the control

valve.

• Ensure that reel, hose, and equipment being serviced are

properly grounded. Use an ohmmeter to check ground

continuity.

• If reel ceases to unwind or rewind, remove system pressure

immediately. Do not pull or jerk on hose!

• Treat and respect the hose reel as any other piece of machinery,

observing all common safety practices.

SAFETY

Personal injury and/or equipment damage may result if proper safety precautions are not observed.

Form# 830-696 Rev: 8/2018

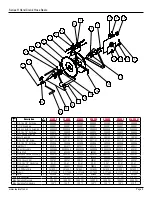

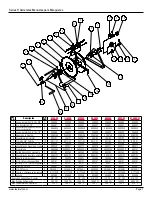

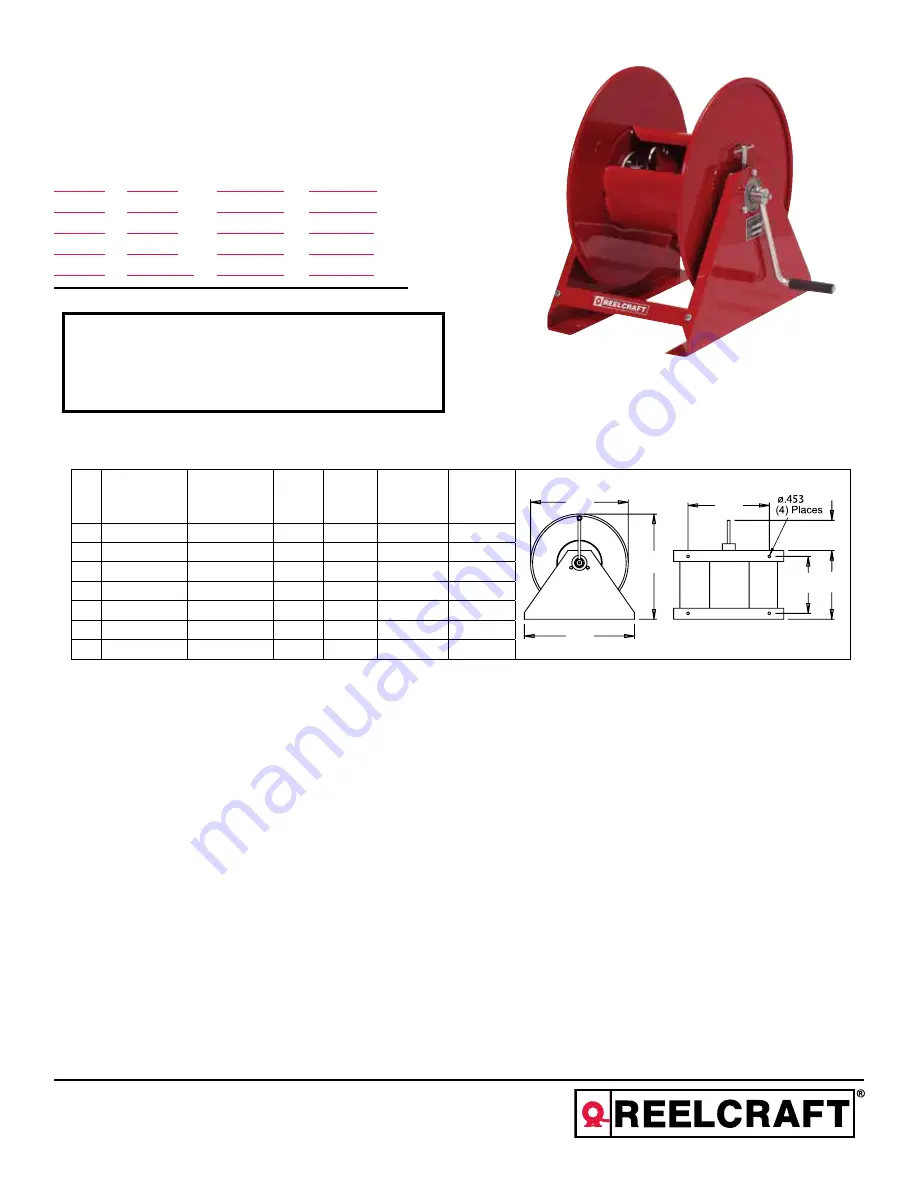

Dimensions

H16000 (M/H)

H18000 (M)

H19000 (M)

H26000 (M/H)

H28000 (M/H)

H29000 (M)

H28005 H29005 H18005 (M) H18006 M

A

19”

19”

20 1/8” 18 7/8”

20 1/8”

20 1/8”

B

20”

20”

14”

14”

14”

14”

C

15”

15”

10”

10”

10”

10”

D

10”

16”

16”

16”

10”

6 3/8”

E

12 1/2”

18 1/2”

18 1/2” 18 1/2”

12 1/2”

8”

F

5 3/4”

5 3/4”

5 3/4”

5 3/4”

5 3/4”

5 3/4”

G

17 3/4”

17 3/4”

17 3/4” 15 3/16”

17 3/4”

17 3/4”

A

B

C

F

D E

G