Series H Hand Crank Hose Reels

Page 2

www.reelcraft.com

INSTALLATION INSTRUCTIONS

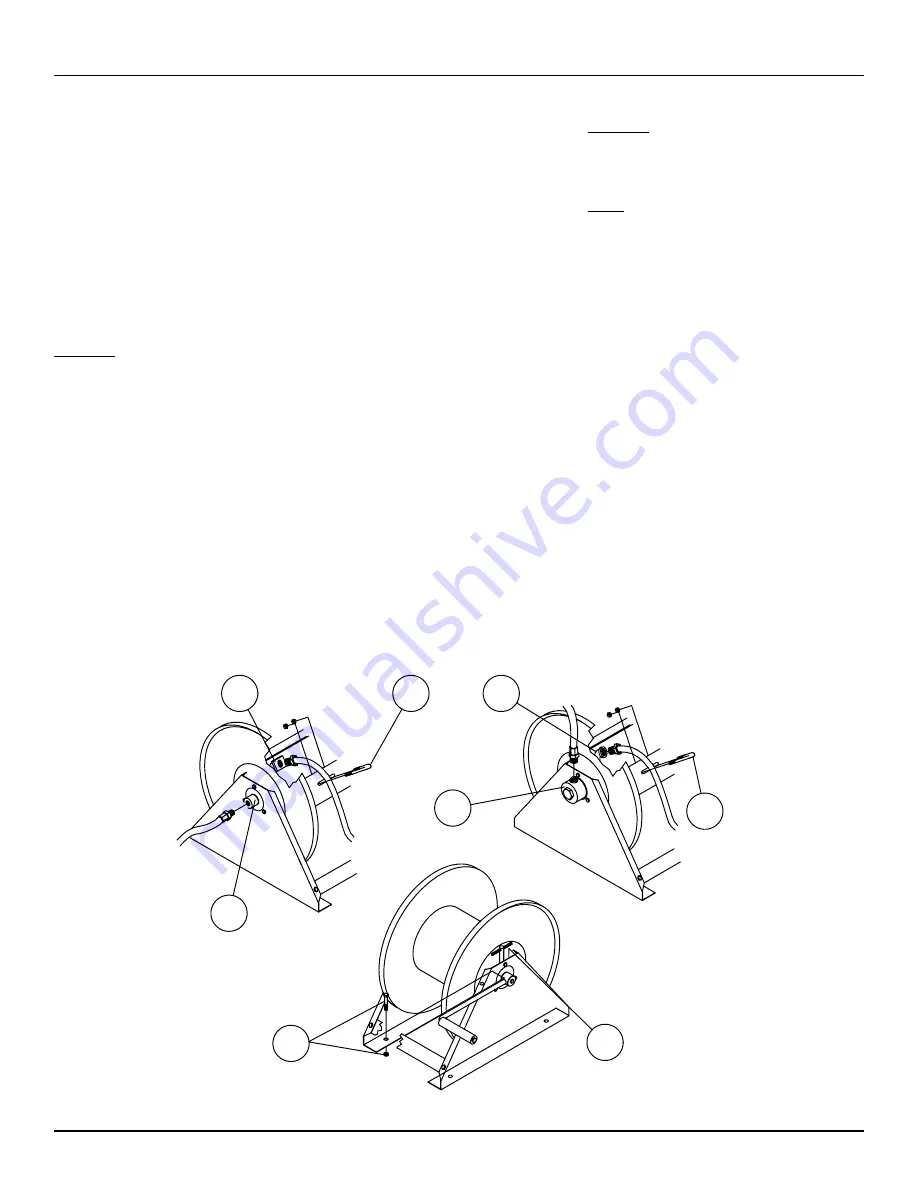

MOUNTING

1. Inspect reel for shipping damage.

Turn by hand to check for smooth

operation. Check for completeness.

2. Position reel to mounting surface and

secure into place, using four (cus-

tomer supplied) screws or bolts (1).

CONNECTING HOSE(S)

Warning:

Ensure that supply line

pressure does not exceed maximum

working pressure rating of reel. Apply pipe

thread sealant to all threads.

1. Connect supply line to swivel/input

shaft (2). It is recommended that a

flexible hose connector be used to

compensate for any offset between

the supply line and swivel.

2. Route output hose through hose

clamp (3).

3. Thread output hose fitting to swivel/

street ell (4). Tighten securely.

4. Tighten hose clamp (3).

5. Fully extend and charge hose.

Momemtarily open control valve to

purge hose of gases. When fluid

appears at control valve, close vavle.

With hose still fully charged, rewind

hose onto reel.

ADJUSTMENTS

REEL DRAG

Adjust reel drag by tightening or loosen-

ing brass set screw (5) (part #4), located

at end of reel opposite swivel.

SERVICE INSTRUCTIONS

Maintain reel by following the service

instructions given below. Refer all other

repairs, other than those listed, only to

an authorized service person or directly

to Reelcraft. Failure to do so can result in

personal injury and/or equipment damage

and may void the warranty.

Warning:

Bleed pressure from system

before performing the following proce-

dures.

Note:

When installing replacement hoses,

apply pipe thread sealant to all threads.

REPLACING HOSES

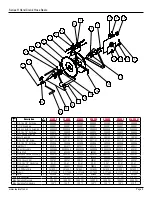

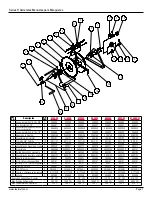

1. Refer to drawings below for help with

replacing/installing the hoses.

1

5

2

3

4

3

4

2