40

l) Checking basic carburettor settings

Fine-tuning of idle motion and full throttle can only be carried out with a well run-in engine.

The carburettor of the built-in FORCE combustion engine stands out for its material combination of plastic and metal. The low heat absorption of the plastic, as

opposed to a carburettor completely made of metal, reduces the amount of fuel mixture evaporating prematurely in the carburettor.

Fuel feeding is thus more precise an easier even when the engine is hot. Carburettor settings remain repeatable and constant during operation.

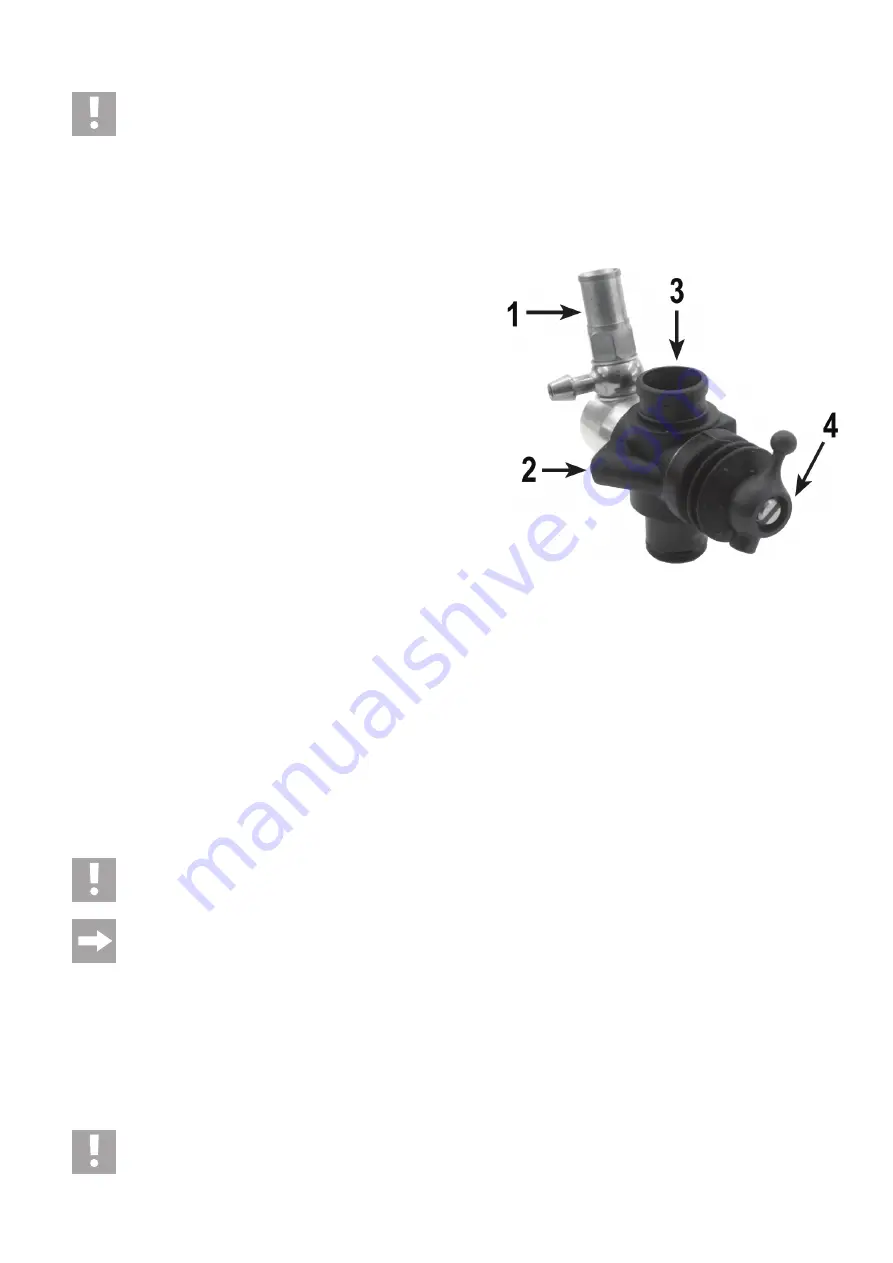

(1) Main jet needle (idle mix adjustment screw)

The main jet needle is located above the fuel supply to the carburettor. It is pre-

adjusted for the first start of the engine and should not be modified yet.

The main jet needle regulates the air-fuel mixture at full throttle.

Turn the screw clockwise to lean the mixture (reduce the fuel ratio) or anti-clockwise

to enrich the mixture (increase the fuel ratio).

For the very first start, the main jet needle should be screwed in completely and then

screwed back between two to three revolutions.

(2) Throttle stop screw (idle speed adjustment screw)

The throttle stop screw is the small screw next to the idle speed adjustment screw. It

is preset and should not need any re-adjustment. The idle speed adjustment screw

regulates the position of the carburettor slide (the throttle stop) and consequently

the carburettor barrel in idle speed.

We recommend a carburettor barrel of approx. 1 - 1.5 mm.

Turning the adjustment screw clockwise widens the barrel, turning it anti-clockwise

causes the slide to move further in which narrows the opening.

(3) Air suction hole

The air filter in installed here.

(4) Idle speed mix adjustment screw

The idle speed mix adjustment screw is the little screw on the side of the carburettor linkage. It is pre-adjusted for the first start and should not be modified yet.

The idle speed mix adjustment screw regulates the air fuel mixture in idle speed and during the transition to full throttle.

Turn the screw clockwise to lean the mixture (reduce the fuel ratio) or anti-clockwise to enrich the mixture (increase the fuel ratio).

Depending on the fuel, the glow plug and the ambient conditions, some minor adjustments might have to be made later.

In order to restore factory settings, proceed as follows:

• Open the carburettor slide completely.

• Keep the slide open and turn the idle speed mix adjustment screw clockwise as far as it will go.

• Now turn it 7.5 revolutions anti-clockwise.

m) Starting the engine

When operating the new engine, a certain run-in time has to be observed. During the run-in time, the engine parts adjust to one another, which

leads to maximal performance and prevents premature wear.

The run-in procedure must be carried out very carefully!

Please note the individual operating instructions of the combustion engine!

Water cooling

• Open the cap of the water tank and fill the tank with clear, clean and cold water.

• When the water tank is filled up, put the cap back on to close it.

• Hold the vehicle in an upright position so that the engine is at the bottom and the water tank is at the top. This allows water to get into the heat sink head. The

air escapes. Wait a short while before putting the car down again in a horizontal position. Refill the tank with water. Repeat this process until the air has

escaped from the tubes and the heat sink head.

• Check the water level in the water tank regularly and refill it if necessary.

Caution, risk of scalding! Only refill the tank when the water in the cooling circuit has cooled down sufficiently. Hot water could spurt out when the

cap on the water tank is opened!

Summary of Contents for 23 65 55

Page 106: ...106 ...

Page 107: ...107 ...