51

d) Adjusting the backlash

The manufacturer has already preset the backlash. As a

rule, no correction is required.

However, vibrations may cause the fixing screws in the

engine to become loose after prolonged use.

If this occurs, the screws must be tightened and you must

check that the backlash is correct.

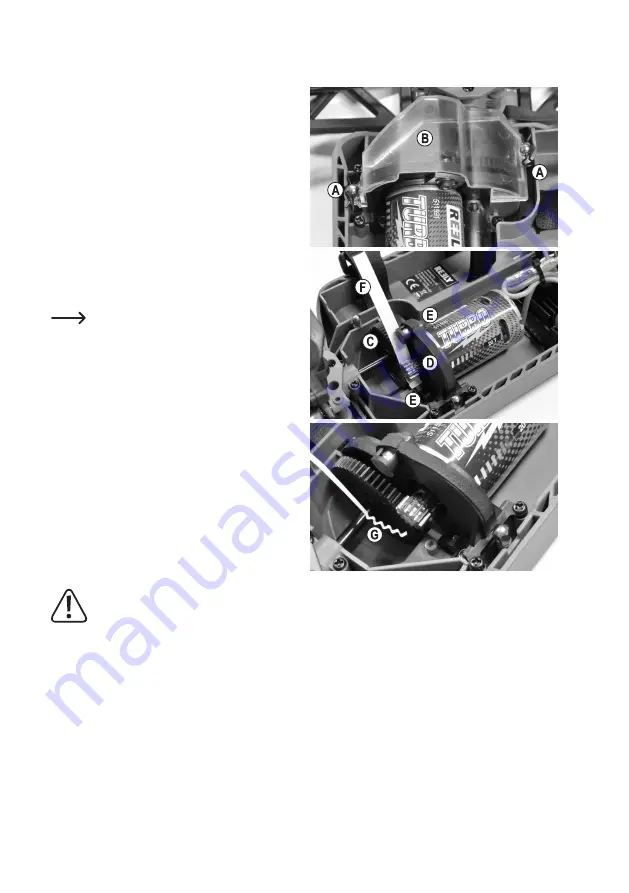

Pull out the two clips (A), then remove the dust cover (B).

Basically, the distance between the main gear (C) and the

engine pinion (D) must be as small as possible, but with-

out the gears running strictly.

Slightly loosen the fixing screws (E) of the engine. Gently

slide the engine with the engine pinion (D) in the direction

of the main gear (C).

The engine must not shake; the fixing screws

should only be loosened enough to allow the

engine to move.

The engine pinion and the main gear will now be engaged

without backlash. However, this is not optimal for the ser-

vice life of the gears!

Place a strip of thin paper (F) between the main gear (C)

and the engine pinion (D). Turn the main gear so that the

paper strip (max. 80 g!) is pulled between the two gears.

The pressure of the paper pushes the electric engine by

the required amount.

Tighten the fixing screws (E) on the engine.

When you turn the main gear in the other direction to re-

move the strip of paper (G), both gears should be at the

correct distance to one another.

Ideally, the engine pinion should be as close as possible to the main gear whilst ensuring that the cogs do

not touch, as this makes the gears too tight.

If the gears (engine pinion and main gear) are too far apart, the cogs on the main gear will be damaged by

the engine pinion after just a few seconds, which will void the warranty/guarantee!

However, if the engine pinion presses against the main gear (i.e. there is no clearance between the cogs),

this will decrease performance, increase power consumption (the engine requires lots of power to turn the

main gear) and lead to premature wear.

Summary of Contents for 2111254

Page 110: ...110 ...

Page 111: ...111 ...