11

11. Setting up the Receiver

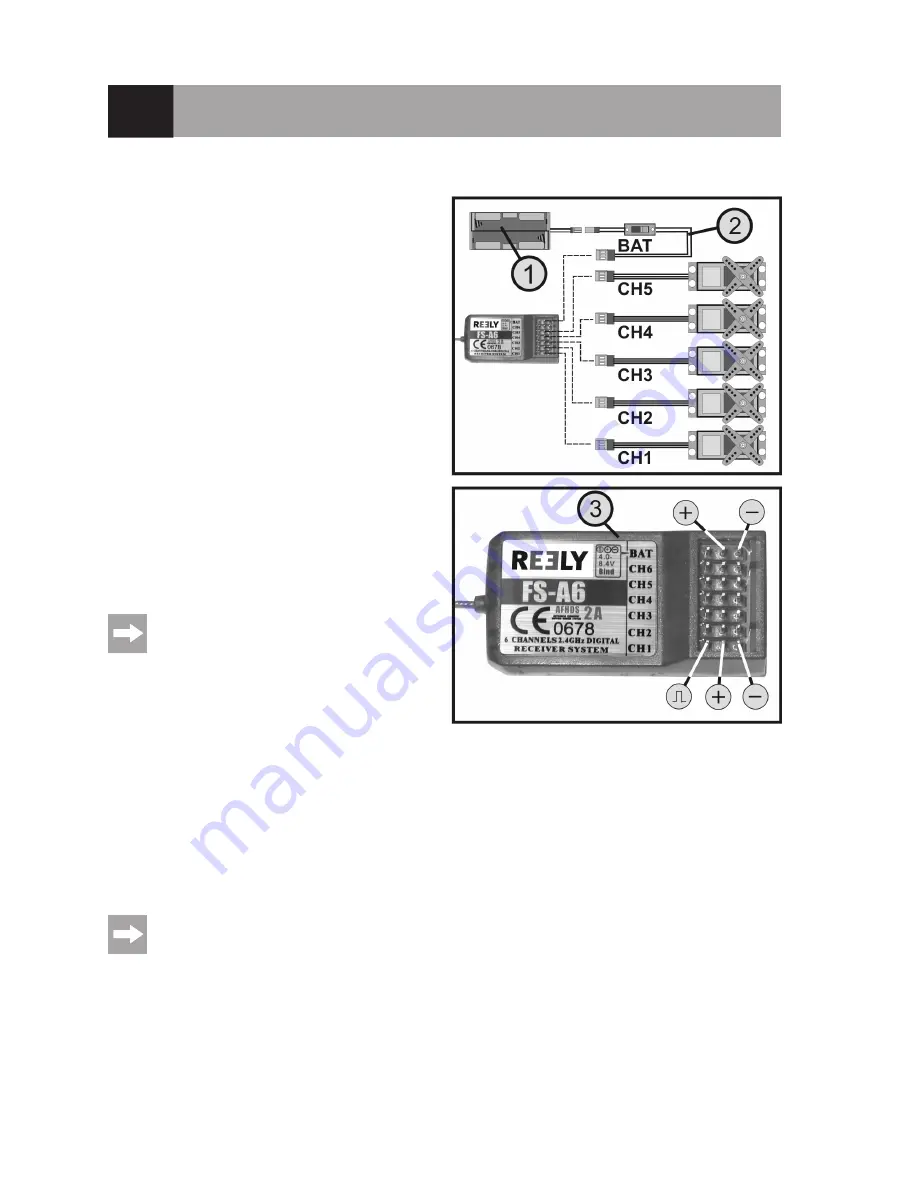

a) Receiver Connection

The receiver offers the possibility of connecting 5 servos

(receiver output "CH1", "CH2", "CH3", "CH4" and "CH5")

that are later assigned the following control functions in

the model:

"CH1" = Aileron/roll servo

"CH2" = Elevator/nod servo

"CH3" = Throttle servo/flight controller/speed controller

"CH4" = Rudder/tail servo

"CH5" = Special function

The receiver output "CH5" can be used for special func-

tions such as landing flaps, spoiler flaps, retractable land

-

ing gear or switching functions.

The receiver output "CH6" is not used, since the transmit-

ter only transmits the first five channels.

At the "BAT" connection, a battery box (1) or a receiver

battery with switch cable (2) is connected if no flight con

-

troller or speed controller with BEC switch is used.

When using servos with high power demand,

we recommend to always use a receiver battery

pack.

The connections are designed for JR plug connectors. If

required, Futaba plugs can be used as well, if a key file or

a sharp knife is used to remove the narrow guide bridge

at the plug.

When connecting servos and speed controllers, always make sure of correct polarity of the plug connectors. The plug-

in connection for the positive lead (yellow, white or orange, depending on the manufacturer) must be connected to the

inner (left) pin contact. The plug-in connection for the negative lead (black or brown, depending on the manufacturer)

must be connected to the outer (right) pin contact.

First, switch on the transmitter and then the receiver. If the binding function is working correctly, the red LED indicator

in the receiver (see figure 5, item 3) lights up and the five servos react to the movements of the control levers. Verify

correct receiver function and then switch the receiver off again.

If the servos do not react and the LEDs in the receiver do flash, perform binding (see chapter 20).

Figure 5

Summary of Contents for HT-5

Page 1: ...Operating instructions Remote Control HT 5 2 4 GHz Item No 1414497 Version 04 16 ...

Page 16: ...16 Figure 10 ...

Page 21: ...21 Figure 14 ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 31: ...31 ...