8540581 - 29/09/2010 - Rev.10

27

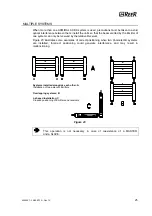

DISTANCE BETWEEN REFLECTING SURFACES

The presence of reflecting surfaces in proximity of the photoelectric barrier may generate

spurious reflections that prevent monitoring. With reference to Figure 25, object

A

is not

detected because surface

S

reflects the beam and closes the optical path between the

Emitter and Receiver. A minimum distance

d

must therefore be maintained between any

reflecting surfaces and the protected area. The minimum distance

d

must be calculated

according to the distance

l

between the Emitter and the Receiver, considering that the angle

of projection and reception is 4°.

Figure 25

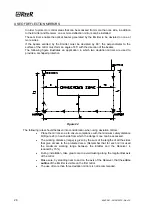

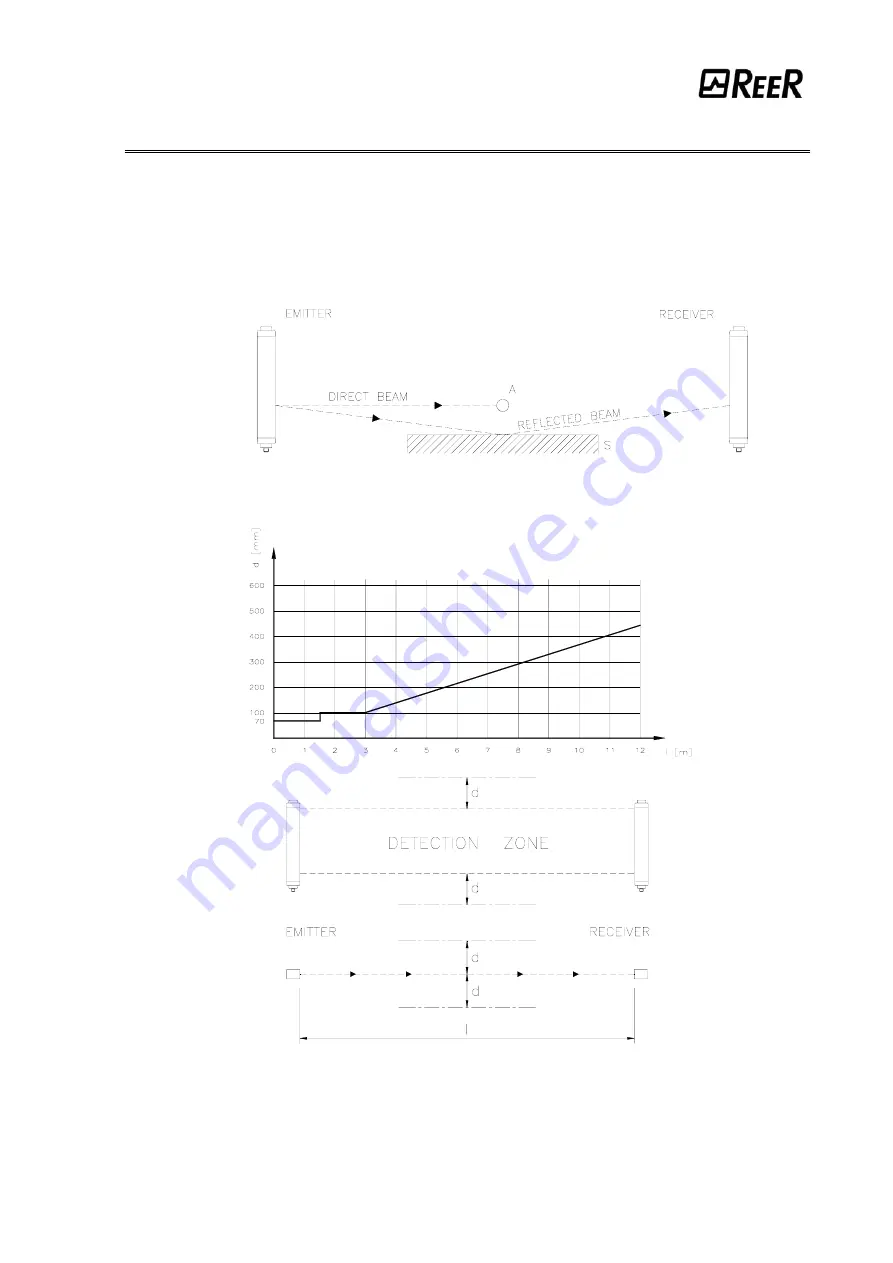

Figure 26 illustrates the values for the minimum distance

d

that must be maintained when

the distance

l

between the Emitter and Receiver is changed.

Figure 26

After installing the system, check whether any reflecting surfaces intercept the beams, first in

the centre and then in the vicinity of the Emitter and Receiver. During these operations, the

red LED on the Receiver should never, for any reason switch off.