VISION VXL

24

8540615 • 19/12/2014 • Rev.8

CHECKOUTS AND MAINTENANCE

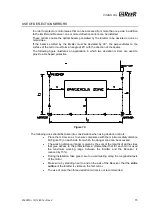

VERIFICATION OF BARRIER EFFICIENCY

Before each work shift or just after switching on, check the correct operation of the

photoelectric barrier.

Proceed as follows, intercepting the beams using the appropriate test object (available on

request).

The correct test object must be used for testing, depending on the barrier resolution.

See page 26 for the correct ordering code.

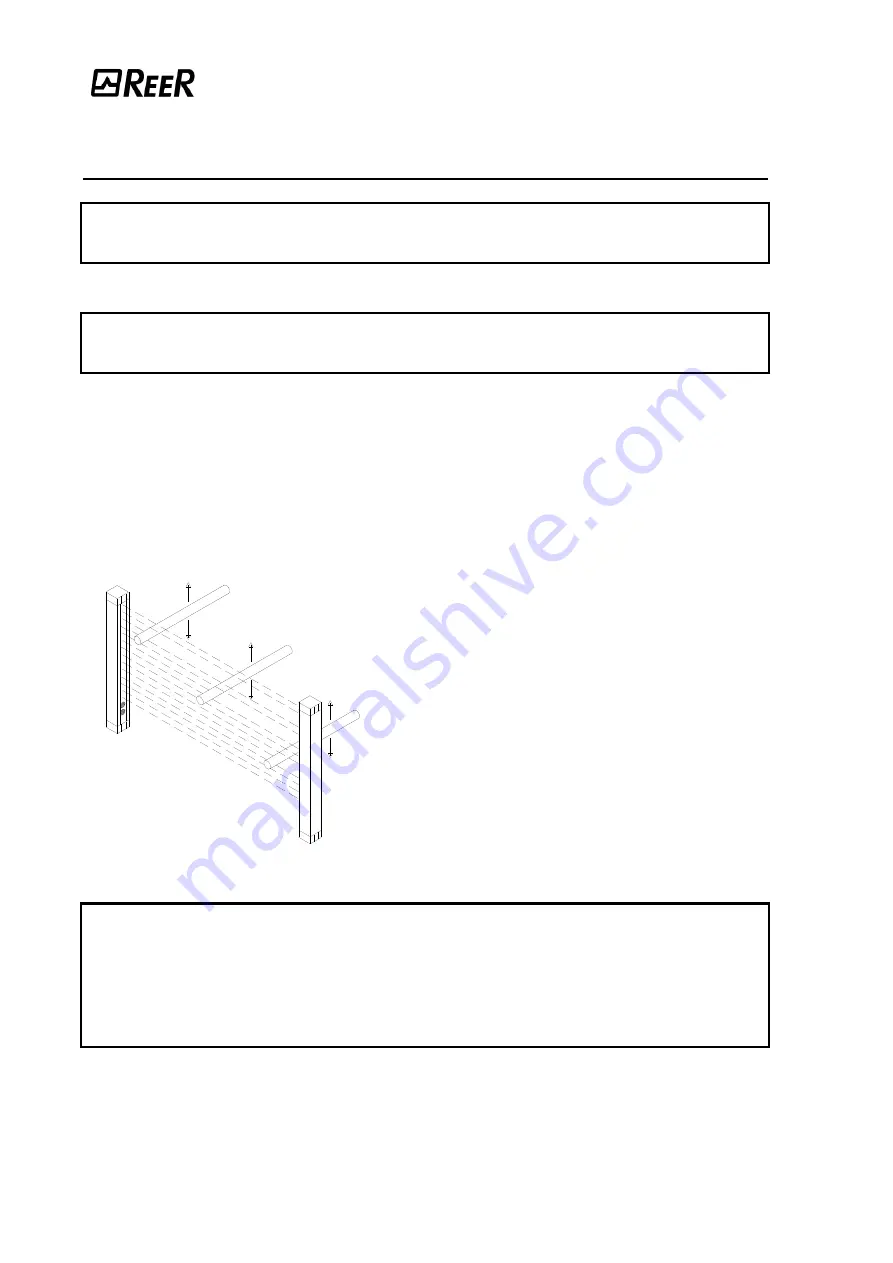

Introduce the test object into the protected area and move it slowly, starting

from the top and moving down (or vice versa), first in the centre and then in the

vicinity of both the Emitter and the Receiver.

Multibeam models:

Intercept each beam with an opaque object, first in the center of the detection

zone and then close to the emitter and the receiver.

Make sure that during each stage of the test object’s movements the red LED

on the Receiver is always on.

Figure 21

The VISION VXL barrier does not require any specific

maintenance operations; however, periodic cleaning of

the front protective surfaces of the Emitter and Receiver

optics is recommended.

Wipe using a clean, damp cloth; in particularly dusty

environments, after cleaning the front surface, the use

of an anti-static spray is recommended.

Never use abrasive or corrosive products, solvents

or alcohol

, which could damage parts. Do not use

woollen cloths, that could electrify the front surface.

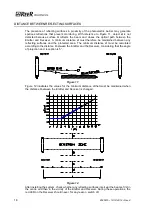

Grooving or fine scratching of the front plastic surfaces can increase the amplitude

of the emission angle of the light curtain, jeopardising detection efficiency in the

presence of lateral reflecting surfaces.

It is therefore fundamental to pay particular attention during the cleaning phases of

the curtain front window, especially in environments where abrasive dusts are

present. (E.g. cement factories, etc).