Installation

Fillcontrol Auto Compact — 20.10.2020 - Rev. D

English — 7

1

Contact water meter (optional accessory)

2

Reflex Fillsoft softening system (optional accessory)

3

Fillcontrol Auto Compact

WC Make-up line to the device

DC Make-up line to the system circuit

LIS Filling level monitoring

•

External signal cable to the Levelcontrol make-up variant

LS Insufficient water switch

PIS Pressure sensor

•

For the Magcontrol make-up variant

Prepare the connection as follows:

1.

Select the "DN" nominal diameter for the make-up lines.

•

At a length of up to 10 metres: DN 15.

•

At a length beyond 10 metres: DN 20.

Flexibly connect the make-up lines.

2.

Flexibly connect the "DC" make-up line to the pump's shut-off valve.

3.

Connect the "DC" make-up line to the system circuit.

4.

Flexibly connect the "WC" make-up line to the shut-off valve of the mains

separator tank.

5.

Connect the "WC" make-up line to the external fresh water main.

The make-up lines are connected.

Note!

Use a pressure reducer in the "WC" make-up line if the mains water

pressure exceeds 6 bar.

Note!

For selecting the make-up variants, see chapter 6.4 "Switching and

make-up variants" on page 7 .

6.4

Switching and make-up variants

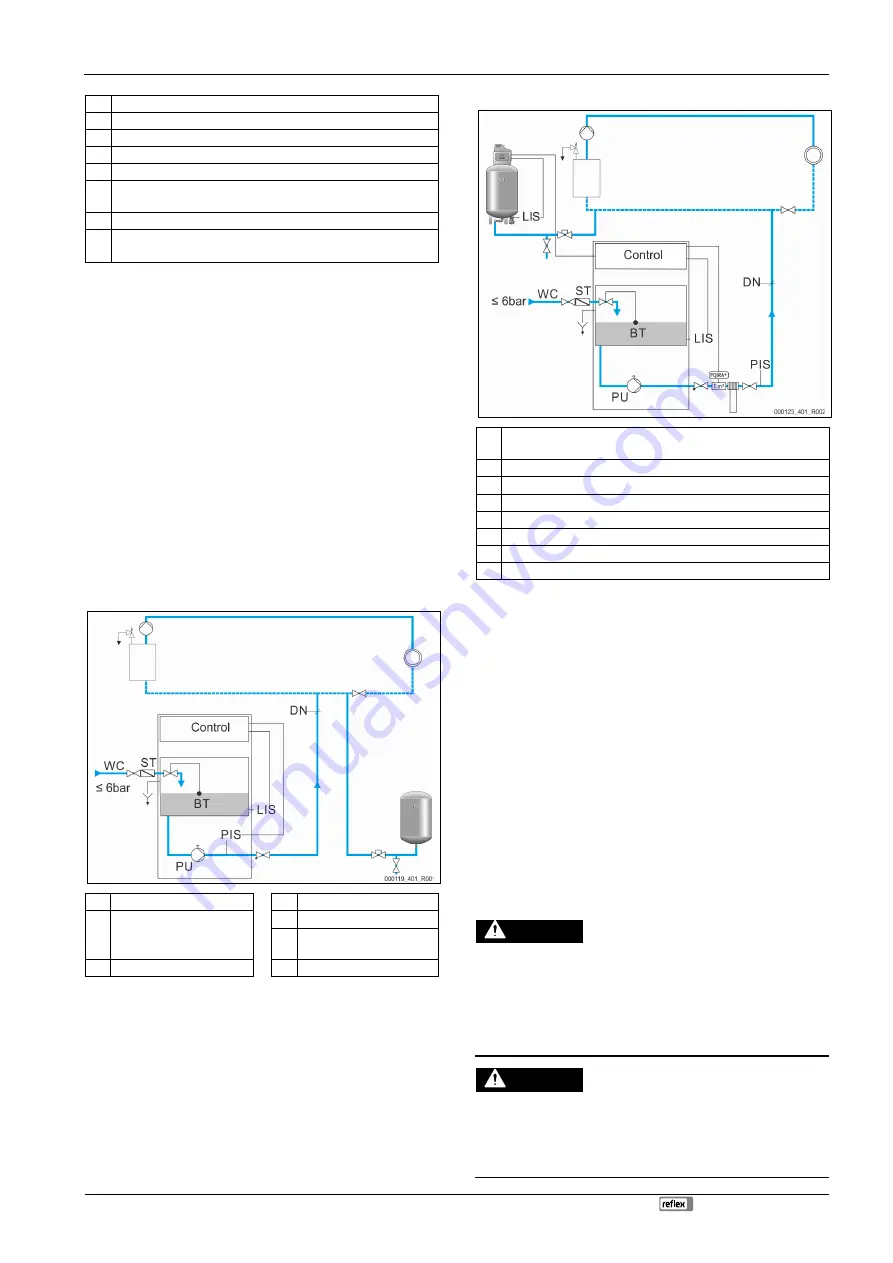

"Magcontrol" pressure-dependent water make-up into the system circuit

WC Make-up line to the device

PU Pump

ST Dirt trap at the shut-off valve

of the mains separator tank

PIS Pressure sensor

DN Nominal diameter of the

make-up line

BT Mains separator tank

LS Insufficient water switch

Water make-up to system circuits with a diaphragm expansion vessel.

The device must be installed in the vicinity of the diaphragm expansion vessel to

ensure that the filling pressure for the fresh water make-up is recorded by the

"PIS" pressure transducer in the device. For calculating the filling pressure, see

chapter 7.2 "Determining the P

minimum operating pressure for the controller"

on page 9 .

"Levelcontrol" level-dependent water make-up into the system circuit.

LIS Level sensor

–

To monitor the filling level in the pressurisation unit

WC Make-up line to the device

ST Dirt trap at the shut-off valve of the mains separator tank

BT Mains separator tank

PU Pump

PIS Pressure sensor

LS Insufficient water switch

DN Nominal diameter of the make-up line

Water make-up to system circuits with a pressurisation unit.

Pressurisation units are equipped with filling level monitors. When the filling

level falls below the minimum level, the pressurisation unit sends a signal to the

device controller. The controller activates the pump. The system circuit is

replenished with fresh make-up water.

Note!

For setting the make-up variants, see chapter 9.2.1 "Customer menu" on

page 12 .

Note!

You may combine the device with softening systems (e.g. Reflex

Fillsoft); available as optional accessories, see chapter 4.6 "Optional

equipment and accessories" on page 5 .

When using a Reflex Fillsoft, the PIS pressure transducer is installed downstream

of the fitting and other installed components, such as a water meter. This

prevents malfunctions when measuring the pressure.

Remove the PIS pressure transducer from the device and fit it in the

corresponding position in the system circuit. To do so, use a T-piece as a

connector in the piping system.

6.5

Electrical connection

DANGER

Risk of serious injury or death due to electric shock.

If live parts are touched, there is risk of life-threatening injuries.

•

Ensure that the system is voltage-free before installing the device.

•

Ensure that the system is secured and cannot be reactivated by other

persons.

•

Ensure that installation work for the electric connection of the device is

carried out by an electrician, and in compliance with electrical

engineering regulations.

DANGER

Risk of serious injury or death due to electric shock

Some parts of the device's circuit board may still carry 230 V voltage even

with the device physically isolated from the power supply.

•

Before you remove the covers, completely isolate the device controller

from the power supply.

•

Verify that the main circuit board is voltage-free.