Technical data

18 — English

Reflexomat XS — 02.16.2022 - Rev. A

If the water level in the primary vessel falls below minimum, a fault message is

output from the controller and displayed in the app as well as via LEDs on the

control panel.

Note!

Additional equipment for topping up water,

4.5

Scope of delivery

The scope of delivery is described in the shipping document and the content is

shown on the packaging.

Immediately after receipt of the goods, please check the shipment for

completeness and damage. Please notify us immediately of any transport

damage.

Basic pressure-maintaining equipment:

•

One 80-litre expansion vessel and one compact design control unit.

•

"LIS" weight measuring cell for filling level measurement.

•

Cap valve

•

Mains cable with plug (230V~)

4.6

Optional equipment and accessories

•

For make-up with water

–

Solenoid "Fillvalve" with ball valve and Reflex Fillset for make-up

with potable water.

•

Fillset Impulse with FQIRA+ contact water meter for make-up with potable

water.

•

Fillsoft for softening or demineralisation of the make-up water from the

potable water system.

–

Fillsoft is installed between Fillset and the device. The device

controller evaluates the make-up quantities and signals the required

replacement of the softening cartridges.

•

Fillguard for conductivity monitoring

–

If the Fillguard is fitted, the capacity of the Fillsoft Zero

demineralisation cartridge can be monitored based on the

conductivity.

•

Optional expansions for Reflex controllers:

–

RS-485 interface with Modbus RTU (integrated).

–

Servitec S

–

Fillcontrol

Note!

Separate operating instructions are supplied with accessories.

5

Technical data

5.1

Control unit

Permissible ambient temperature

+5 – +40 °C

Degree of protection

IP 42

Noise level

72 dB

Electrical power

max. 250 W

Electrical supply

230 V / 50 Hz

Fusing

4 A

Electrical voltage control unit

230 V / 2 A

Number of RS-485 interfaces

1

Weight

28 kg

Permissible operating temperature

0 – 70 °C

Permissible flow temperature

90 °C

Operating pressure

0.5 - 3.5 bar

Safety valve (PSv max)

6 bar

Heating capacity

Up to approx. 400 kW

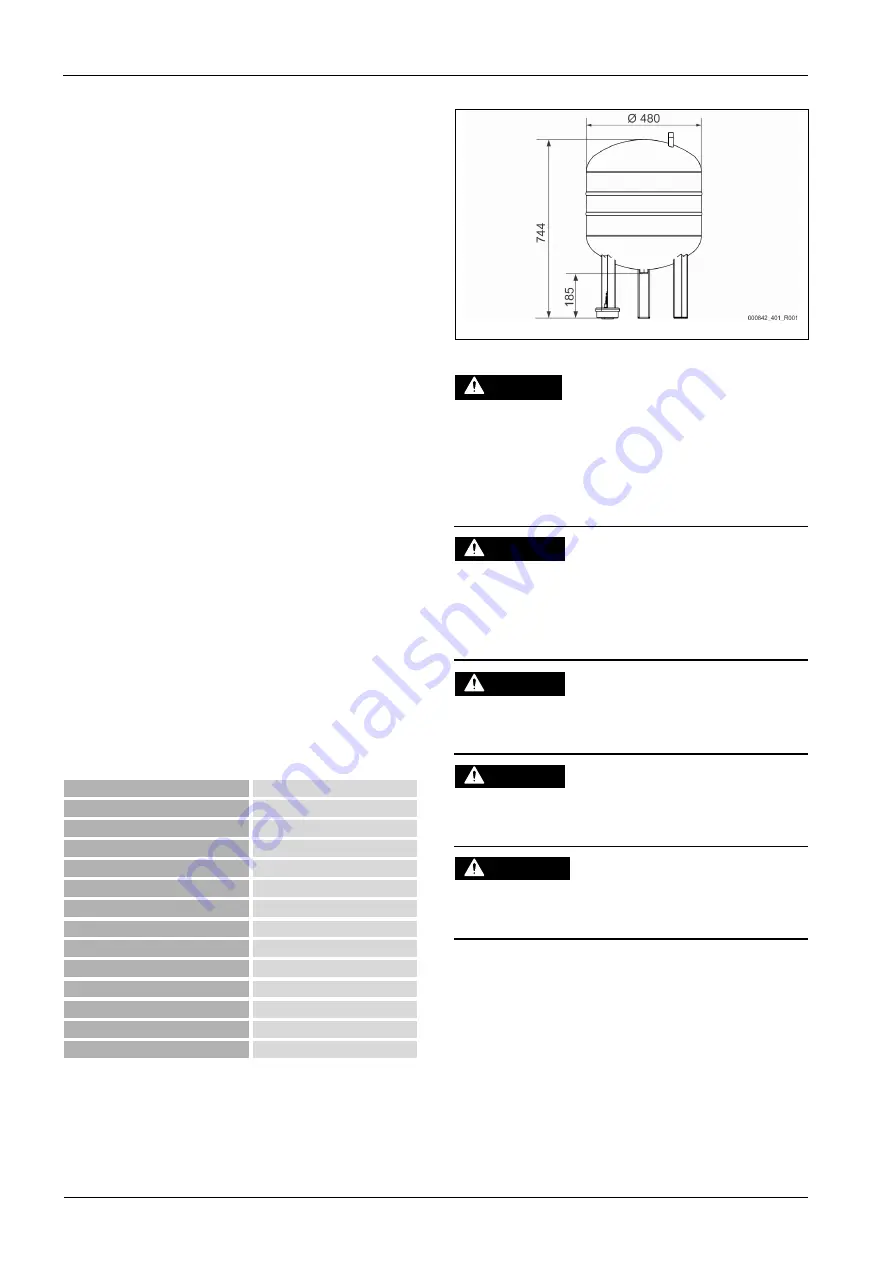

5.2

Vessel

Vessel without controller (volume 80 l)

6

Installation

DANGER

Risk of serious injury or death due to electric shock.

If live parts are touched, there is risk of life-threatening injuries.

•

Ensure that all phases of the mains power supply to the product are

disconnected prior to installation.

•

Ensure that the system is secured and cannot be reactivated by other

persons.

•

Ensure that installation work for the electric connection of the device is

carried out by an electrician, and in compliance with electrical

engineering regulations.

CAUTION

Risk of injury due to pressurised liquid

If installation, removal or maintenance work is not carried out correctly, there

is a risk of burns and other injuries at the connection points, if pressurised

hot water or hot steam suddenly escapes.

•

Ensure proper installation, removal or maintenance work.

•

Ensure that the system is de-pressurised before performing installation,

removal or maintenance work at the connection points.

CAUTION

Risk of burns on hot surfaces

Hot surfaces in heating systems can cause burns to the skin.

•

Wear protective gloves.

•

Please place appropriate warning signs in the vicinity of the device.

CAUTION

Risk of injury due to falls or bumps

Bruising from falls or bumps on system components during installation.

•

Wear personal protective equipment (helmet, protective clothing,

gloves, safety boots).

WARNING

Risk of injury due to heavy weight

The devices are heavy. Consequently, there is a risk of physical injury and

accidents.

•

Use suitable lifting equipment for transportation and installation.

Note!

Confirm that installation and start-up have been carried out correctly

using the installation and commissioning certificate. This action is a

prerequisite for the making of warranty claims.

–

Have the Reflex Customer Service carry out commissioning and

the annual maintenance.

6.1

Installation conditions

6.1.1

Incoming inspection

Prior to shipping, this device was carefully inspected and packed. Damages

during transport cannot be excluded.

Proceed as follows:

1.

Upon receipt of the goods, check the shipment for

–

completeness and

–

possible transport damage.

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz