Installation

20 — English

Reflexomat XS — 02.16.2022 - Rev. A

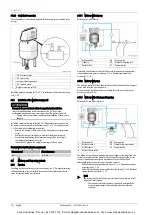

6.3.2.2

Control unit connection

The connections are located on a manifold in the housing (pre-assembled in the

factory).

1

"PIS" pressure sensor

2

"SV" safety valve

3

Compressed air connection

4

"PV" solenoid valve

5

Weight measuring cell "LIS"

Install the weight measuring cell,

6.3.3 "Installation of the weight measuring

6.3.3

Installation of the weight measuring cell

ATTENTION

Damage to the pressure load cell due to unprofessional installation

Incorrect installation may result in damage to the "LIS" level sensor,

malfunctioning and incorrect measurements from the pressure load cell.

•

Comply with the instructions regarding the installation of the pressure

load cell.

Install the weight measuring cell for the "LIS" filling level measurement, when

the primary vessel is located in the final position,

19. Comply with the following instructions:

•

Remove the transport safety device at the mounting foot of the primary

vessel.

•

Replace the transport safety device with the weight measuring cell.

•

Avoid shock-type loading of the load measuring cell by, for example,

subsequent alignment of the vessel.

•

Install the M12 plug on the weight measuring cell. (hand-tight)

Standard values for filling level measurements:

Primary vessel

Measuring range

80 l

0 – 4 bar

6.4

Make-up and degassing variants

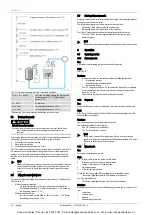

6.4.1

Function

The filling level in the primary vessel is measured by the "LIS" weight measuring

cell and evaluated in the controller. When the water level falls below the set

value, the external make-up is activated.

6.4.1.1

Make-up without pump

Reflexomat XS with Fillvalve.

1

Reflexomat XS

WC

Make-up line

2

Fillvalve

LIS

Weight measuring cell

3

Reflex Fillset

EC

Expansion line

Preferably, you should use the Reflex Fillset with integrated system separator

when using potable water for make-up,

6.4.1.2

Make-up with pump

The make-up systems, Reflex Fillcontrol Auto or Reflex Fillcontrol Auto Compact

can be used for make-up with a pump.

Water make-up with Fillcontrol Auto is suitable for make-up at high system

pressures of up to 8.5 bar.

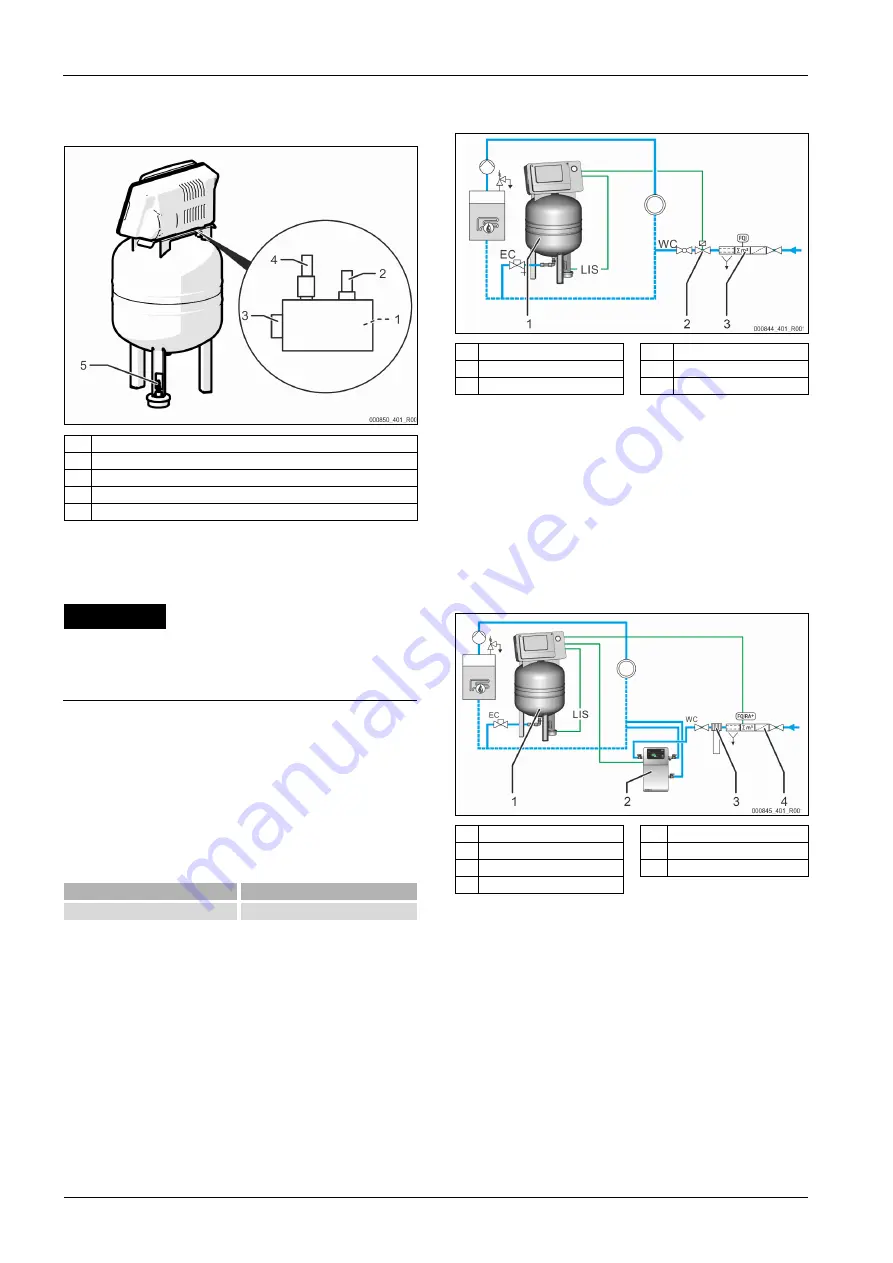

6.4.1.3

Make-up with softening and degassing

Reflexomat XS and Reflex Servitec S.

1

Reflexomat XS

WC Make-up line

2

Reflex Servitec S

LIS Filling level measurement

3

Reflex Fillsoft

EC Expansion line

4

Reflex Fillset Impulse

The Reflex Servitec S degassing and make-up unit degasses the water from the

system circuit and the make-up water. The automatic make-up for the system

circuit is controlled by the pressure maintenance system. Reflex Fillsoft

additionally softens or demineralises the make-up water.

•

Reflex Servitec degassing and make-up unit,

•

Reflex Fillsoft softening system and Reflex Fillset Impulse,

Note!

In a setup with a Reflex Fillsoft water treatment system, always install

the Reflex Fillset Impulse.

•

The controller evaluates the make-up quantity and signals the

necessary replacement of the softening or demineralisation

cartridge.

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz