Installation

Vacuum spray degassing — 06.07.2016 - Rev. B

English — 17

6.1

Installation conditions

6.1.1

Incoming inspection

Prior to shipping, this device was carefully inspected and packed. Damages during transport cannot be excluded.

Proceed as follows:

1. Upon receipt of the goods, check the shipment for

•

completeness and

•

possible transport damage.

2. Document any damage.

3. Contact the forwarding agent to register your complaint.

6.2

Preparatory work

Condition of the delivered device:

•

Check all screw connections of the device for tight seating. Tighten the screws as necessary.

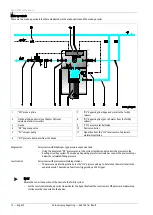

Preparing the connection of the device to the plant system:

•

Barrier-free access to the plant system.

•

Level and solid placement surface for the device.

•

Frost-free, well-ventilated room.

– Room temperature > 0 - 45 °C.

•

Drain for drain water.

•

Filling connection.

– DN 15 according to DIN 1988 T 4.

•

Electric connection.

– 230 V~, 50 Hz, 16 A with upstream ELCB (tripping current: 0.03 A).

Summary of Contents for Servitec 30

Page 2: ......

Page 56: ...Annex 56 English Vacuum spray degassing 06 07 2016 Rev B...

Page 57: ......