Description of the device

Vacuum spray degassing — 06.07.2016 - Rev. B

English — 13

4.5

Scope of delivery

The scope of delivery is described in the shipping document for the initial shipment and the content is shown on the packaging.

Immediately after receipt of the goods, please check the shipment for completeness and damage. Please notify us immediately of any

transport damage.

Basic degassing equipment:

•

Device

•

3 ball valves for degassing and makeup connections

•

Operating manual

4.6

Optional equipment and accessories

The following optional equipment and accessories are available for this device:

•

Fillset for make-up with water.

– Fillset with integrated backflow preventer, water meter, dirt trap, and locking mechanisms for the "WC" make-up line.

•

Fillset Impulse with FQIRA+ contact water meter for make-up with water.

– If the Fillset Impulse with FQIRA+ contact water meter is installed in the make-up line, you can regulate the entire make-up

quantity and the soft water capacity of Fillsoft softening systems. The operational reliability of the device is assured and

prevents the automatic make-up during major water loss or small leaks.

•

Fillsoft for softening the make-up water from the public water network.

– Fillsoft is installed between Fillset and the device. The device controller evaluates the make-up quantities and signals a

required replacement of the softening cartridges.

•

Enhancements for the device controller.

•

Use the RS-485 interface to retrieve various data from the controller and to communicate with control centres or other

devices.,see chapter 6.5.2.1 "Connecting the RS-485 interface" on page 28 . You need the following items for the

communication of the RS-485 interface with control centres or other devices:

– Bus modules for the communication with control centres

– Lonworks Digital

– Lonworks

– Profibus-DP

– Ethernet

– I/O module for standard communication

•

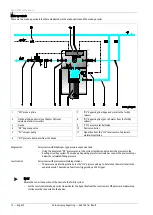

Reflexomat for system with pressure-maintaining stations.

– The Reflexomat and device combination is preferred. Despite the degassed network, Reflexomat assured an extremely elastic

operation at constant pressure. Make-up is executed depending on the water level measured with the "LIS" level sensor of the

Reflexomat in the expansion tank of the pressure maintaining station. For a make-up request, the Reflexomat controller

activates a 230 V signal to the device controller.

•

Gas discharge measurement for an optimised degassing operation.

Notice!

Separate installation, operation, and maintenance instructions are supplied with the accessories and optional equipment.

Summary of Contents for Servitec 30

Page 2: ......

Page 56: ...Annex 56 English Vacuum spray degassing 06 07 2016 Rev B...

Page 57: ......