250

Chapter 8

FIBERGLASS & GELCOAT

Routine maintenance is the only practical way to keep the

surface of your boat looking shiny and new. Most objects

left outdoors will gradually deteriorate from exposure to

the sun, water, dust and pollution. Such outdoor expo

-

sure can cause your boat’s gelcoated surface to change

or fade. Darker colors tend to fade more rapidly than

lighter colors because they absorb more of the sun’s rays

(ultraviolet and infrared).

Basic maintenance includes monthly washing of the

boat’s surface to remove normal accumulation of soil and

stain. Use a mild detergent such as dishwasher powder

or liquid. Do not use automatic dishwasher detergent.

Avoid any kind of alkaline cleaners such as tri-sodium

phosphate (TSP), abrasives, bleaches and ammonia.

For best results use cleaners that are recommended for

fiberglass.

When the washing and waxing as recommended does not

restore the shine it may be necessary to use a fine rubbing

compound. Do not apply rubbing compound in direct

sunlight. A power buffer at lower speeds does an excel

-

lent job to remove impurities from the gel coat that cause

dulling. Use light pressure and keep the buffer moving.

Re-wax after compounding to buff the surface.

“Hairline cracks” or “spider webbing” could develop in

the gelcoat surface of a hull or deck. This can be caused

by impact or other factors. Small air pockets or gouges

may also occur through normal

wear.

These do not affect

the strength of the hull or deck and can be repaired by

yourself, a marine professional or a Regal dealer.

The affected area should be chipped or sanded away and

a thin layer of color matched gelcoat applied. This layer

is then sanded smooth and buffed to its original luster.

Most minor scratches, nicks, and dents can be removed

by compounding the surface. Marine type compounds can

be found at most auto body supply stores.

Specify a number 25 which is a coarser compound up to a

number 55

being less coarse. Various glazes and polishes

are available as needed. Ask your marine professional or

Regal dealer for more information. Fiberglass hulls are

strong but they can be damaged. A fiberglass hull has vir-

tually no internal stresses. Thus when a part is broken or

punctured, the rest of the hull retains its original shape. A

severe blow will either be absorbed or result in a definite

localized break. A break of this nature should be checked

and repaired by a marine professional or a Regal dealer.

MINOR REPAIRS

You will need the following materials for minor repairs:

•

Gelcoat

•

Clear Liquid Catalyst

•

Putty Knife

•

Razor Blade

•

Fine Sandpaper (400,600,1000)

•

Wax Paper (to cover repair area)

It is recommended that you wax the gelcoat surface twice

yearly to prevent loss of gloss and to protect the finish.

Use only waxes for fiberglass and follow the label instruc-

tions. Apply a 3’ x 3’ section at a time using clean applicator

cloths or a buffing bonnet. When a haze develops, use a

power buffer at low speeds (1200-2000 rpm) to remove

the haze. Keep the buffer moving to avoid heat build-up.

Never wax gelcoat in direct sun.

Summary of Contents for 26 EXPRESS

Page 1: ...OWNER S MANUAL 26 EXPRESS 26 XO 4 2019...

Page 28: ...28 Chapter 2 NAVIGATION LIGHT RULES...

Page 50: ...50 Chapter 3...

Page 51: ...51 Rules Of The Road...

Page 73: ...73 Systems TYPICAL 12 VOLT HELM SWITCH PANELS PORT SWITCH PANEL STARBOARD SWITCH PANEL...

Page 121: ...121 Systems...

Page 122: ...122 Chapter 4...

Page 123: ...123 Systems...

Page 124: ...124 Chapter 4...

Page 125: ...125 Systems...

Page 126: ...126 Chapter 4...

Page 127: ...127 Systems...

Page 128: ...128 Chapter 4...

Page 129: ...129 Systems...

Page 130: ...130 Chapter 4...

Page 153: ...153 Engine Controls REGAL 26 XO TANK LABEL...

Page 177: ...177 Engine Controls SEA STAR STEERING SYSTEM SCHEMATIC OVERVIEW...

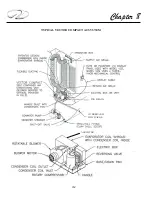

Page 262: ...262 Chapter 8 OVERBOARD DISCHARGE PAN DRAIN TYPICAL VECTOR COMPACT AC SYSTEM AIR FILTER...

Page 275: ...275 Cosmetic Care Maintenance...

Page 294: ...294 Chapter 9 HOT WATER HEATER...

Page 298: ...298 Chapter 9 STEREO DIAGNOSTIC CHART...

Page 299: ...299 Troubleshooting STEREO DIAGNOSTIC CHART...

Page 300: ...300 Chapter 9 STEREO DIAGNOSTIC CHART...

Page 303: ...303 Troubleshooting THRUSTER BOW...

Page 304: ...304 Chapter 9 TYPICAL WINDLASS...

Page 321: ...321 Technical Information TECHNICAL DRAWINGS...

Page 325: ...Technical Information 322 26 EXPRESS GALVANIC ISOLATOR WIRING...

Page 326: ...Technical Information 323 TYPICAL NMEA 2000 NETWORK COMPONENTS...

Page 328: ...Technical Information 325 26 EXPRESS TYPICAL DC GROUND CIRCUITRY...

Page 329: ...Technical Information 326 26 EXPRESS TYPICAL TRIM TAB SWITCH CIRCUITRY...

Page 330: ...Technical Information 327 26 EXPRESS TYPICAL GFCI CIRCUITRY...

Page 331: ...Technical Information 328 26 EXPRESS TYPICAL FIRE EXTINGUISHER GROUND CIRCUITRY...

Page 332: ...Technical Information 329 26 EXPRESS TYPICAL STEREO BLUETOOTH WIRING EARLIER...

Page 333: ...Technical Information 330 26 EXPRESS TYPICAL SWITCH PANEL HARNESS PLUG CIRCUITRY...

Page 334: ...Technical Information 331 26 EXPRESS TYPICAL SWITCH PANEL CIRCUITRY...

Page 335: ...Technical Information 332 26 EXPRESS BATTERY MANAGEMENT PANEL FRONT CIRCUITRY...

Page 336: ...Technical Information 333 26 EXPRESS BATTERY MANAGEMENT PANEL REAR CIRCUITRY...

Page 337: ...Technical Information 334 26 EXPRESS DOMESTIC 120 VOLT MAIN AC PANEL...

Page 338: ...Technical Information 335 26 EXPRESS OVERSEAS 230 VOLT MAIN AC PANEL...

Page 339: ...Technical Information 336 26 EXPRESS DOMESTIC 120 VOLT MAIN AC PANEL...

Page 340: ...Technical Information 337 26 EXPRESS GALLEY ELECTRIC BREAKOUT 1...

Page 341: ...Technical Information 338 26 EXPRESS GALLEY ELECTRIC BREAKOUT 2...

Page 342: ...Technical Information 339 26 EXPRESS GALLEY ELECTRIC BREAKOUT 3...

Page 343: ...Technical Information 340 26 EXPRESS GALLEY ELECTRIC BREAKOUT 4...

Page 344: ...Technical Information 341 26 EXPRESS GALLEY ELECTRIC BREAKOUT 5...

Page 345: ...Technical Information 342 26 EXPRESS GALLEY ELECTRIC BREAKOUT 6...

Page 347: ...Technical Information 344 26 EXPRESS MACHINERY LAYOUT PROFILE VIEW EXPLODED...

Page 348: ...Technical Information 345 26 EXPRESS MACHINERY LAYOUT TOP VIEW EXPLODED...

Page 353: ...Technical Information 350 26 EXPRESS TYPICAL BOW PLAN WINDLASS...

Page 359: ...Technical Information 356...

Page 360: ...Technical Information 357...

Page 361: ...Technical Information 358...

Page 362: ...Technical Information 359...

Page 363: ...Technical Information 360...

Page 364: ...Technical Information 361...

Page 365: ...Technical Information 362...

Page 366: ...Technical Information 363...

Page 367: ...Technical Information 364...

Page 368: ...Technical Information 365...

Page 369: ...Technical Information 366...

Page 370: ...Technical Information 367...

Page 371: ...Technical Information 368...

Page 373: ...Technical Information 370...

Page 374: ...Technical Information 371...

Page 375: ...Technical Information 372...

Page 376: ...Technical Information 373...

Page 377: ...Technical Information 374...

Page 379: ...Technical Information 376...

Page 381: ...Technical Information 378...

Page 382: ...Technical Information 379...

Page 383: ...Technical Information 380...

Page 384: ...Technical Information 381...

Page 386: ...Technical Information 383...

Page 387: ...Technical Information 384...

Page 388: ...Technical Information 385...

Page 389: ...Technical Information 386...