Manual - TC.P Quadro

Commissioning

2016-08-05

60/330

V04.52

3

3.2.4.5. Output connection/load connection

The output connections are laid to the rear side of the device as current

bars.

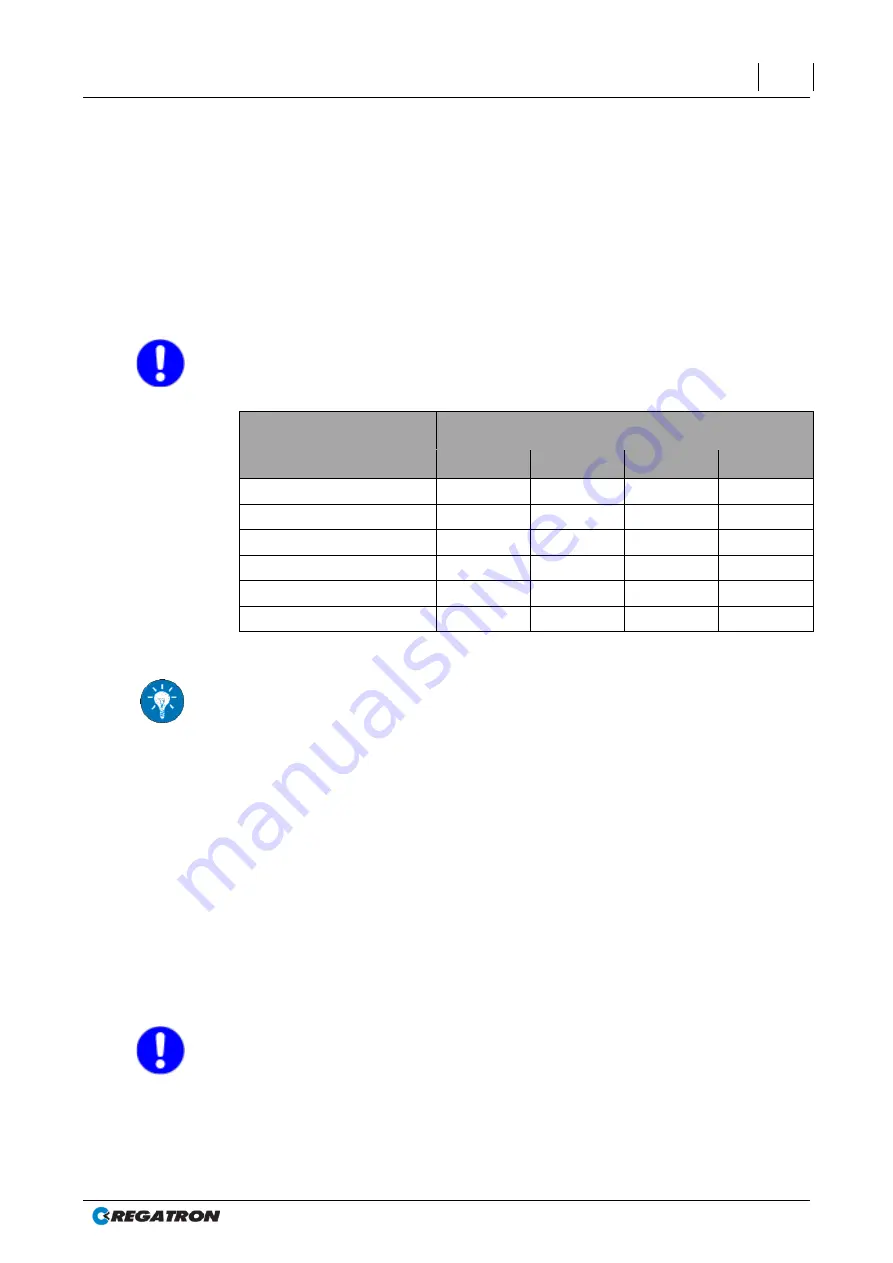

For the load connection you must pay attention to the following aspects:

Use a cable cross-section to suit the device power and nominal

voltage.

(See Table 35, 60.)

Screw cable to current bars using cable lugs

Hole diameter: 9 mm

Follow the standards applicable to the related application and type of

cable laying. The values in the table are only a recommendation.

Nominal voltage

on the output

Cross-section [mm

2

] - load cable

TC.P.10

TC.P.16

TC.P.20

TC.P.32

50 V

50

70

95

150

100 V

35

50

70

70

200 V

16

25

35

50

500 V

4

10

16

25

1000 V

2.5

4

6

10

1200 V

2.5

4

6

10

Table 35

Cross-section sizing for the load cable as a function of the output voltage.

For cable lengths of more than 5 m the next size cross-section up

should be selected to keep the voltage drop over the load cable in lim-

its.

3.2.4.6. System-internal CAN communication (X101/102)

TopCon power supplies that are operated in a multi-unit system require

system-internal communication via the related interfaces X101/X102.

The tasks of the individual TopCon power supplies and their peripheral

modules, e.g. RCUs and series controllers are controlled via the CAN

communication. At the same time the CAN communication is used for

communication between the system master and the slaves assigned.

The interfaces X101 and X102 have the following tasks:

CAN interface, for the communication

Interlock connection

The related interface must always be “terminated”, i.e. fitted with the re-

lated dummy plugs or a bus connection.