Regency Plateau

®

PTO30-11 Outdoor Gas Fireplace

e |

25

25

|

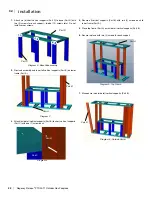

installation

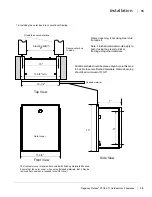

PTO60 WALL SWITCH AND BATTERY INSTALLATION

(INCLUDED WITH UNIT)

919-070

08/15/11

2

OUTDOOR SERIES

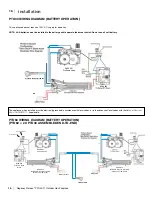

PTO60 / PTO100 WALL SWITCH INSTALLATION

(INCLUDED WITH UNIT)

Note: Each PTO30 / PTO50 comes with a wall switch. However, only

one

wall switch is required. The 2nd switch can either be discarded or saved as

a spare part.

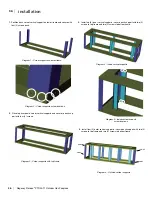

The units come with a low voltage wire and a battery extension wire in-

stalled on each burner.

1)

Run supplied wire to desired location - to a max. of 9 feet for both

burners.

2)

Install supplied electrical box in desired location.

3)

Remove center knock out from electrical box and install strain relief

(strain relief nut not required).

4)

Connect both sets of low voltage wires together from each burner - white

with white and black with black.

5)

Route low voltage wires and battery extension wire through the strain

relief.

Note:

Ensure the battery extension wires are approx. 8" in length inside the

electrical box.

This excess will ensure ease of battery replacement and servicing in

the future.

8)

Using silicone, completely seal strain relief to protect from water or moisture.

9)

Place supplied gasket on top of electrical box.

10)

Fasten cover to electrical box using supplied screws.

11)

Place switch in OFF position until fi nal installation is complete.

Center knock out

Slide 1st battery

pack to the right.

Strain Relief

6)

Attach low voltage wires to the switch - ensure to attach on the right side

of the switch. This will make it easier to remove the 2nd battery terminal

when replacing batteries. Fasten switch to right side of electrical box as

shown below.

7)

Install 4- AA batteries into each battery terminal. Ensure correct polarity.

Slide the fi rst battery terminal all the way to the right - until it is next to the

switch.

The 2nd battery terminal can be attached to the battery cover with the

supplied velcro.

NOTE:

PTO60 is two PTO30 units assembled end to end.

PTO100 is two PTO50 units assembled end to end.

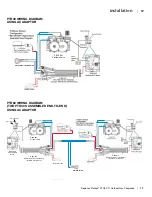

WARNING:

Failure to position the parts in accordance with these

diagrams or failure to use only parts specifically approved with this ap-

pliance may result in property damage or personal injury.

Summary of Contents for Plateau PTO30

Page 45: ...Regency Plateau PTO30 11 Outdoor Gas Fireplacee 45 45 notes ...

Page 50: ......

Page 51: ......