Regency B36XTCE Gas Fireplace

45

INSTALLATION

B

E

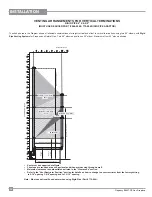

A

B

D

Notch location on underside

of Log A

(runs from back - front)

Right Peg - Log E

6)

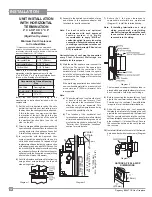

Position Log D with the fl at side toward Log E.

Fit Log D into right peg on Log E.

D

5)

Place Log A on the front right side of the burner. Position the notch

on the bottom right side of the log into the right side of the grate.

Slide Log A back towards Log E until the fl at surface on Log A rests

up against the tabs on the burner and grate - this maintains a

necessary gap between Logs A & E.

Note:

Use the notch on the bottom of Log A as a guide -see below.

Tabs on

burner &

grate

Back of Log A

A

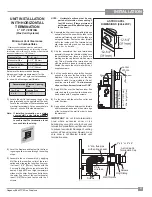

7)

The notch on the bottom of Log D rests against the knot on

Log A (as shown below).

A