28

|

City Series ACB60E

installer's information

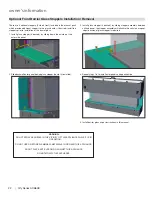

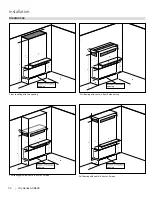

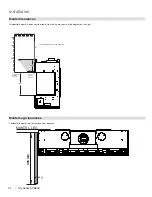

Access Panel Removal

The front access panels (x3) and one (x1) on the right side

(facing unit front) may be removed for ease of hooking up gas

and electrical--prior to finishing. Once complete ensure that the

access panel is reinstalled prior to any finishing.

See locations in diagram to the right.

Note: Once the finished material is installed, these access

panels are no longer accessible.

Access panel removal

The front access panels (x3) may be removed for ease of

hooking up gas and electrical--prior to finishing. Once complete

ensure that the access panel is reinstalled prior to any finishing.

See locations in diagram to the right.

Note: Once the finished material is installed, these access

panels are no longer accessible.

tooltip

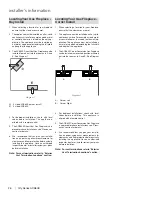

Gas connection

Electrical

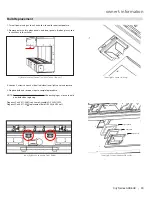

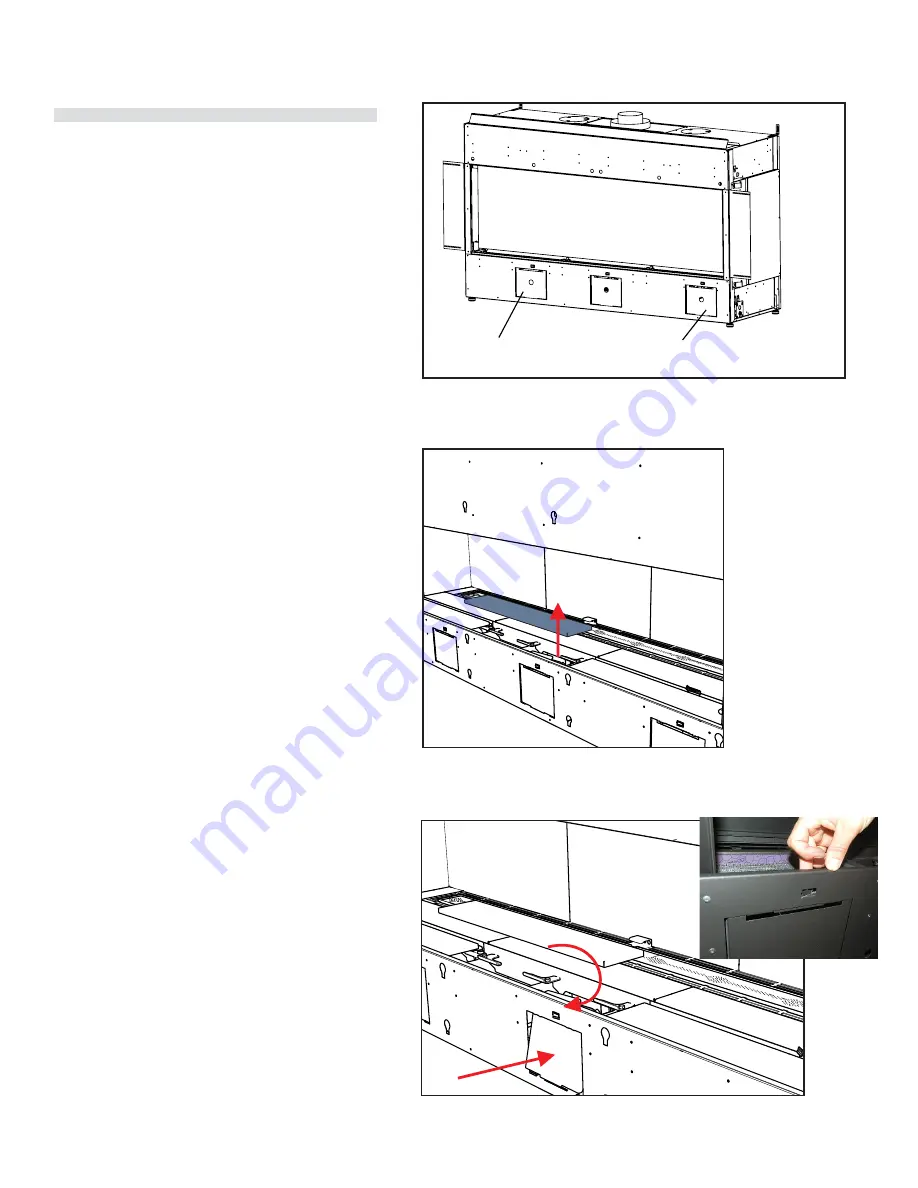

1. Identify access panel to be removed, remove corresponding

outer trim panel by lifting up and off (centre panel shown

below).

2. From inside the unit--push in tab to release the access

panel at the top.

3. Push the access towards the inside of the unit, lift up from

the bottom to release bottom tabs, when clear, lift out of unit.

4. Reverse steps to reinstall access panel.

tooltip

tooltip

1. Identify access panel to be removed, remove corresponding

outer trim panel by lifting up and off (centre panel shown

below).

2. From inside the unit—push in tab to release the access

panel at the top.

3. Push the access towards the inside of the unit, lift up from

the bottom to release bottom tabs, when clear, lift out of unit.

4. Reverse steps to reinstall access panel.

Summary of Contents for City ACB60E

Page 95: ...City Series ACB60E 95 notes ...

Page 102: ...102 City Series ACB60E notes ...

Page 103: ...City Series ACB60E 103 notes ...