52

|

Regency

®

E18 Gas Fireplace Insert

|

52

installation

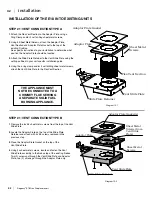

LOG TRAY INSTALLATION

LOG SET INSTALLATION

919-190

10/03/12

1

E18

LOG TRAY INSTALLATION

1. Remove the Log Burner Tray from the box. Hang the front

burner cover on the front edge of the burner tray. Place the Log

Burner Tray on the Glass Burner Tray.

LOG SET INSTALLATION

2. Screw the Log Burner Tray to the Glass Burner Tray.

3. Install the Log Burner the same way as the Glass Burner (see

installation manual for instructions).

4. Fill the Log Burner with 2lbs of black glass crystals.

2. Place Log B at the front left of the Log Tray.

Read the instructions below carefully and refer to the images. If the logs

are broken do not use the unit until they are replaced. Broken logs can

interfere with pilot operation.

Improper positioning of the logs may create carbon build-up and can

alter the unit's performance which is not covered under warranty.

Log Kit #619-935 contains the following pieces:

1. Place Log A over the two posts at the back of the log burner.

Installation of Panels must be completed before

installing the log set.

* Log instructions shown with Black Enamel Panels

A

A

B

A

Rear Log

B

Front Left Log

C

Front Right Log

D

Left Side Log

E

Right Side Log

946-675

2lb Fireglass

946-669

Platinum Embers

946-708

Embaglow Embers

1C Ember Lava

616-515

Log Tray Assembly

Screws x 2

Summary of Contents for E18-LP

Page 1: ......

Page 74: ...Regency E18 Gas Fireplace Insert 73 73 notes ...

Page 75: ...74 Regency E18 Gas Fireplace Insert 74 notes ...