11

U20/E21 Gas Insert Zero Clearance Kit

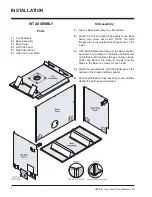

INSTALLATION

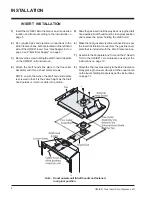

Diagram 4

10) Attach the brass trim to the faceplate by drilling a

1/8" (3mm) hole through the faceplate using the

hole in the trim as a guide. Fasten the trim to the

faceplate panels using the plated screws. #10

x1/2". See diagram 4 detail 'B'.

11) Attach the faceplate panels to the insert body

using the 4 remaining black screws. See diagram

4 detail 'A'. These screws will also fasten the

insert to the Zero Clearance sides.

12) Push the logo plate into the two holes in the

bottom left corner of the faceplate.

Note: This faceplate and Hearth Trim Assembly

replaces the standard Assembly as shown

in the U20/E21 Installation Manual.

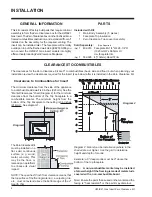

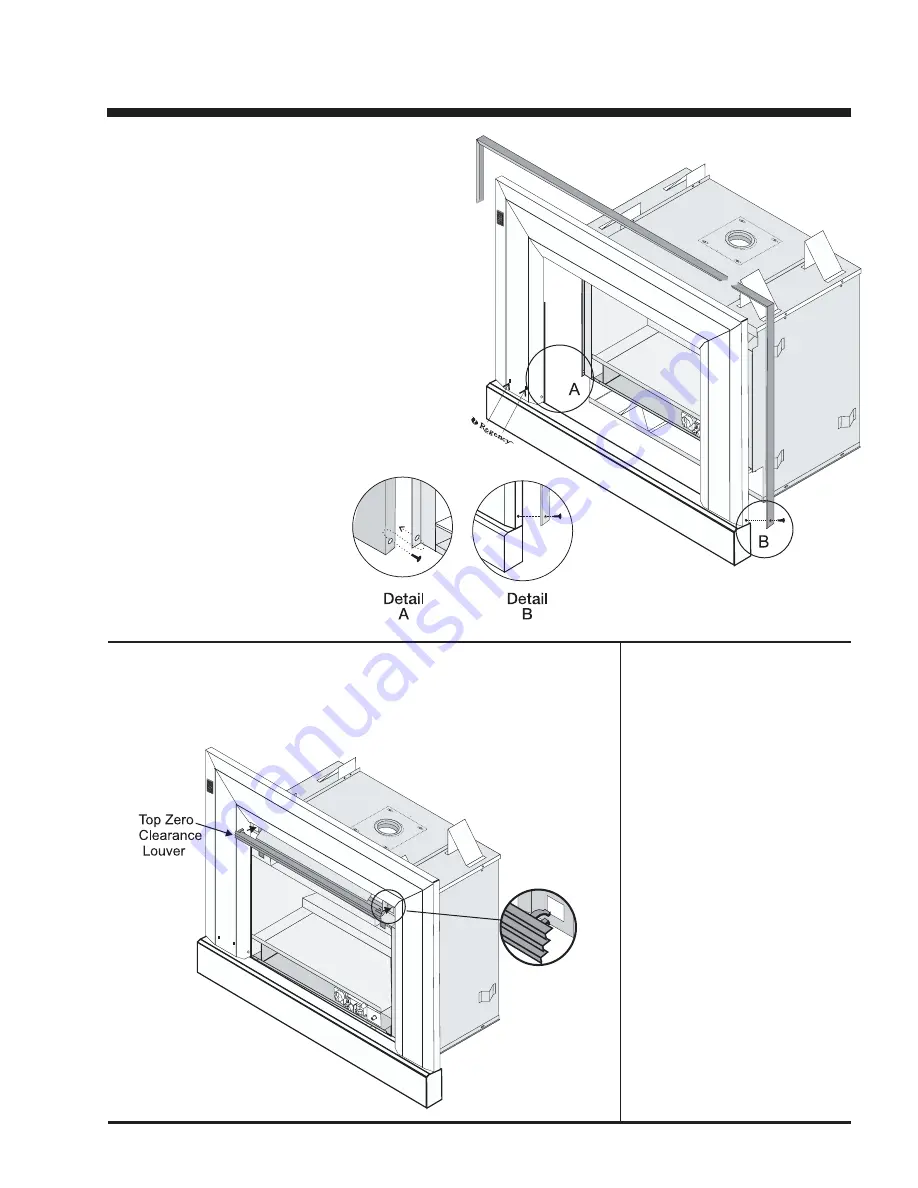

FINISHED FACING

NOTES

Install finished facing surface

of 1/2"(13mm) thickness on

framing. Drywall 1/2" (13 mm)

thick can extend flush with the

appliance on all three sides of

the front face. The height at

which the mantle must be

installed above the top louver

depends on the depth of the

mantle. If the mantle is to be

painted, use a heat resistant

paint to prevent discolouration.

ZERO CLEARANCE TOP LOUVER

Attach the Top louver assembly to the Zero Clearance box by placing the

louver clamps into the square hole on the louver holding brackets.

Summary of Contents for Energy E21

Page 12: ...Printed in Canada ...