12

F37 Regency

®

Rear Flued Room Sealed Freestanding Gas Heater

System Data - F37

Burner Inlet Orifi ce Sizes:

NG LPG

Burner

#37

#52

Max. Input Rating

31.7 mj

Min. Input Rating

16 mj

Supply Pressure

NG

min.

1.13kPa

LPG

min.

2.75kPa

Manifold Pressure

NG

.89

kPa

LPG

2.55

kPa

GAS CONNECTION

The gas connection is a 1/2" NPT Male

Thread. Copper can be used or other con-

nections approved by AG 604.

When using copper or fl ex connectors use only

approved fi ttings. Always provide a union so

that gas lines can be easily disconnected for

burner and/or valve servicing. Flare nuts for

copper lines are usually considered to meet

this requirement.

Important: Always check for gas leaks with a

soap and water solution or gas leak detector.

Do not use open fl ame for leak testing.

Note: Prior to any pressure testing of

the gas supply piping system

that exceeds test pressures of

3.45 kPa, this appliance must

be disconnected from the pip-

ing system. If test pressures

equal to or less than 3.45 kPa

are used then this appliance

must be isolated from the piping

system by closing its individual

manual shut-off valve during the

testing.

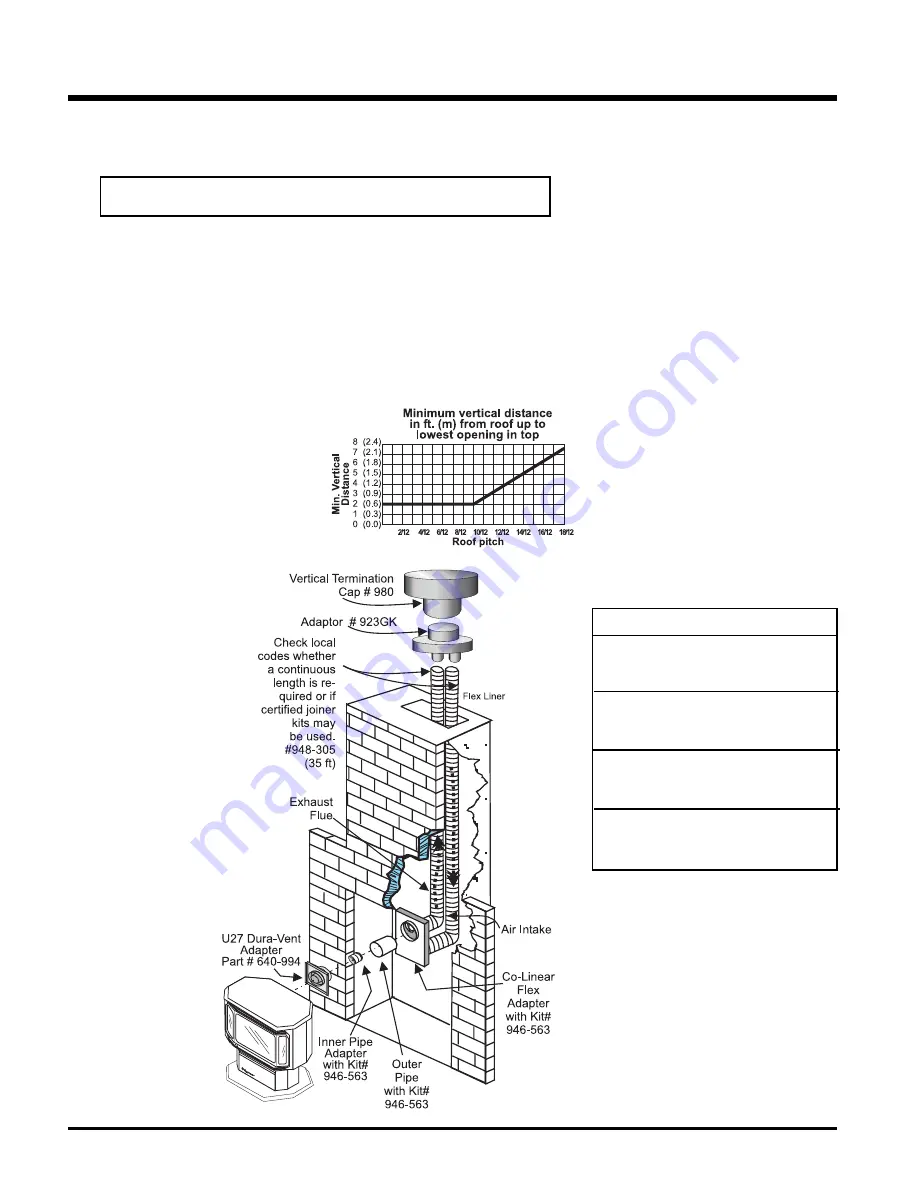

VERTICAL TERMINATION WITH

CO-LINEAR FLEX SYSTEM

THE APPLIANCE MUST NOT BE CONNECTED TO A CHIMNEY FLUE SERVING

A SEPARATE SOLID FUEL BURNING APPLIANCE.

This appliance is designed to be attached to two 3" (76mm) co-linear aluminium fl ex running the

full length of the chimney. See the Flueing Arrangements chart in the "Flue Arrangement" sec-

tion for minimum and maximum fl ue lengths. See chart below for minimum distances from roof.

Periodically check that the fl ue is unrestricted.

Masonry chimneys may take various contours which the fl exible liner will accommodate. However,

keep the fl exible liner as straight as possible

, avoid unnecessary bending.

The Air Intake pipe must be attached to the inlet air collar of the termination cap.

Required Parts:

Part #

Description

946-529

Co-linear DV Vertical Termination Cap

948-305

3" Flex - 35 ft.

640-994 F37

Dura-Vent

Adapter

946-563

Co-Axial to Co-Linear Adapter Kit

which contains the following:

Co-linear

Flex

Adapter

(270-585)

Outer

Pipe

(946-257)

Inner

Pipe

Adapter

(946-219)

Approved Caps

980 Vertical

Termination

Cap

923GK 3"

Co-linear

Adapter

with

fl

ashing

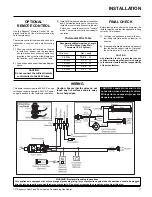

INSTALLATION