Regency FG39-1 FireGenie Freestanding Gas Stove

19

INSTALLATION

918-578

12/20/06

4

PG121-1 / PG131-1 / FG39-1

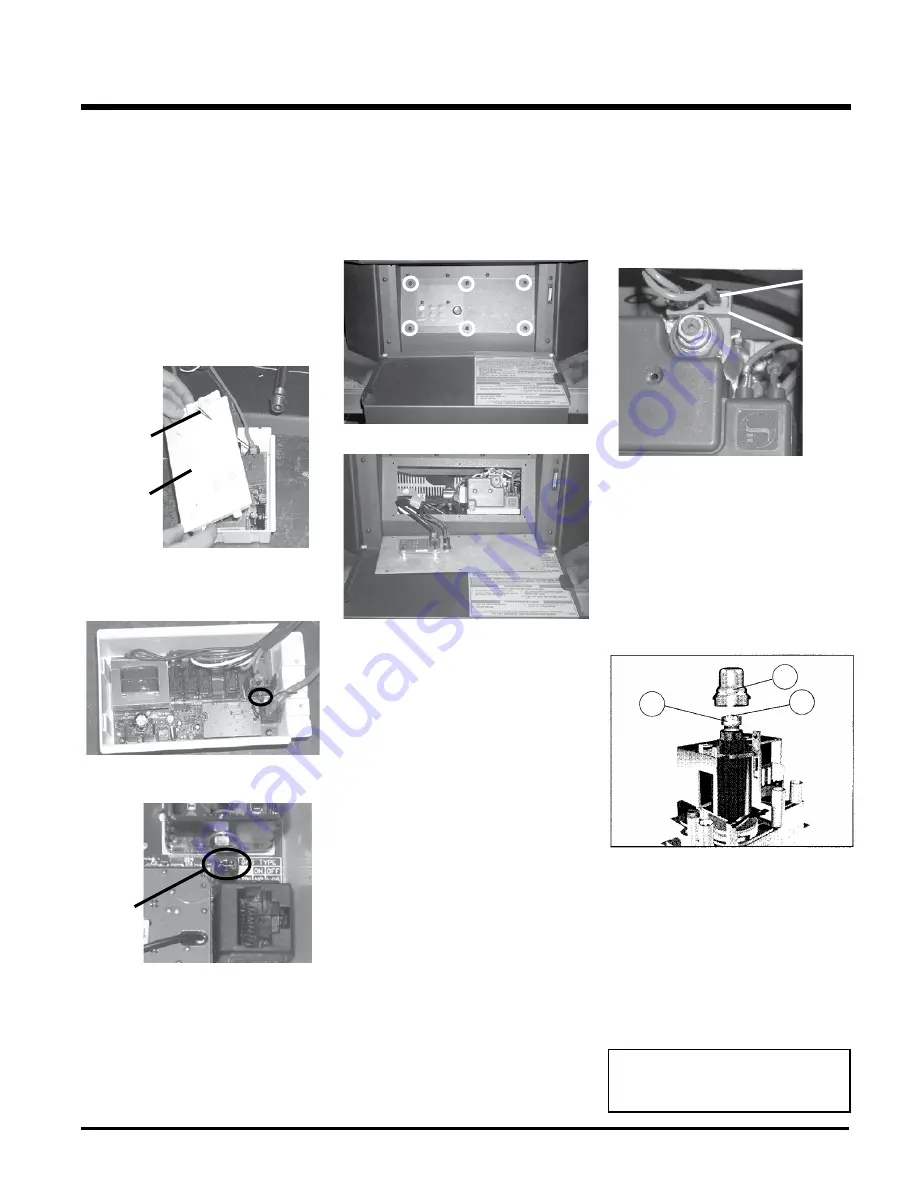

12)

Stick the conversion label "This unit has

been converted to LPG" over top of the

serial number decal.

13)

Replace the yellow "NG" label with the red

"LPG" label.

14)

Carefully pull out the control box.

Note:

The control box is held in place by

velcro.

15)

Remove the control box cover by undoing

the 3 screws. Maneuver through antenna.

Control Box

Cover

Antenna

17)

Stick the conversion label "This unit has

been converted to LPG" on the control box

cover.

18)

Reverse steps 15, 14 & 11.

19)

Open the bottom door and remove the front

panel by undoing the 6 screws.

16)

Remove the jumper using a plier.

After carrying out all adjustments, block

the setting screws with paint, taking care

not to obstruct the breather orifi ce of the

pressure.

Put back the modulator plastic cap.

WARNING:

To ensure the correct opera-

tion of the modulator it is necessary that

the plastic cap (A) is returned to its original

location.

Cable

Electric

Modulator

21) Adjusting the Outlet Pressure

All the adjustments must be carried out in

the following order:

Remove the modulator plastic cap (A) using

needle nose pliers.

Maximum pressure:

Turn the unit ON to

its highest input rating. Screw in the nut (B)

to increase the outlet pressure and screw

it out to decrease it. Use a 10 mm wrench.

NOTE:

The outlet pressure must be set to

maximum 2.65 kPa.

20)

Turn on the gas supply and plug in the power

cord.

Installer Notice:

These instructions must be left

with the appliance.

22)

At the end of all setting and adjustment

operations, check electrical insulation and

gas leaks.

23)

Reverse step 19.

24)

Check operation of fan and fl ame control.

25)

Check for proper fl ame appearance and

glow on logs.

C

B

A

Minimum pressure:

Remove one of the

cables connected to the electric modulator.

Keeping the nut (B) blocked, screw in the

screw (C) to increase the pressure and screw

it out to decrease it. Use a screwdriver 6 x

1 blade.

NOTE:

The outlet pressure must be set to

minimum 0.74 kPa.

Jumper

Jumper Location