Regency GF900C Gas Fireplace

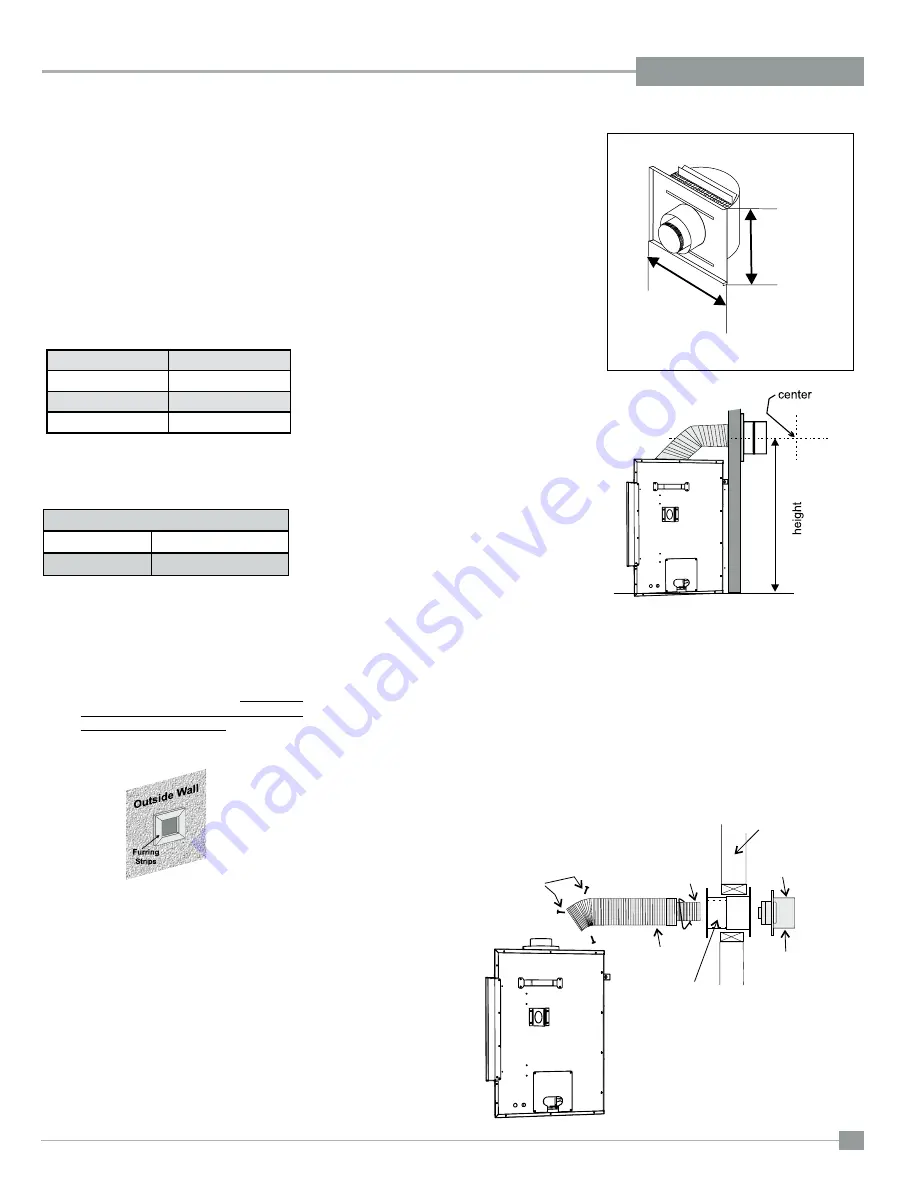

25

INSTALLATION

1)

Locate the unit in the framing, rough in the gas

(preferably on the right side of the unit). Locate

the centerline of the termination and mark wall

accordingly. Cut an square hole in the wall - see

chart (inside dimension).

Note: If installing termination on a siding cov-

ered wall, a vinyl siding standoff or vinyl

furring strips must be used to ensure that

the termination is not recessed into the

siding.

2)

Level the fireplace and fasten it to the framing

using nails or screws through the nailing strips.

3)

Assemble the vent assembly by applying Mill

Pac to the inner flue collar of the termination and

slipping the inner flex liner over it at least 1-3/8"

(35mm). Fasten with the 3 screws (drilling pilot

holes will make this easier). Apply Mill Pac or

high temperature silicone to the outer flex pipe

and slip it over the outer flue collar of the vent

terminal at least 1-3/8"(35mm) and fasten with

the 3 screws.

11”

(279mm)

11”

(279mm)

ASTROCAP

DIMENSIONS (946-523/P)

Minimum Vent Clearances

to Combustibles

UNIT INSTALLATION

WITH HORIZONTAL

TERMINATION

4" X 6-5/8"

(

102MM X 175MM)

VENTING

(Flex Vent Systems)

NOTE: Horizontal sections must be supported

at intervals not exceeding 3 feet (0.9

meter). (Flame picture and performance

will be affected by sags in the liner).

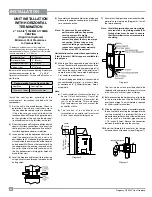

4)

Separate the 2 halves of the wall thimble and

securely fasten the one with the tabs to the

outside wall making sure that the tabs are on

top and bottom. Fasten the other thimble half

to the inside wall. The thimble halves slip inside

each other and can be adjusted for 2 x 4 or 2

x 6 walls.

5)

Slip the assembled liner and termination

assembly through the thimble making sure the

termination cap faces up (there are markings

on the cap indicating which way is up). This will

position the termination cap with proper down

slope for draining water. Fasten the cap to the

outer wall with the 4 supplied screws.

6)

Pull the centre inner and outer flex liner out

enough to slip over the flue collars of the

fireplace. (You may wish to cut the liner shorter

to make it more workable.) Do not bend liner

more than 90

o

.

The liners must slip over the

collars a minimum of 1-3/8".

7)

Apply Mill Pac over the fireplace inner flue

collar and slip the inner flex liner down over it

and attach with 3 supplied screws.

8)

Do the same with the outer flue collar and outer

flex liner.

9)

Apply a bead of silicone between the thimble

and termination and around the outer edge of

the terminal at the wall in order to keep the

water out.

IMPORTANT:

Do not locate termination hood

where excessive snow or ice buildup may

occur. Be sure to check vent termination

area after snow falls, and clear to prevent

accidental blockage of venting system. When

using snow blowers, make sure snow is not

directed towards vent termination area.

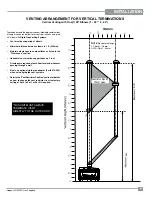

* Clearances noted below must be maintained;

except when passing through a wall, ceiling or at the

termination where the use of a firestop or wall thimble

reduces clearance to 1" (25mm).

Below are the recommended framing dimensions

(inside measurements) for the 4" x 6-5/8" rigid

vent terminations - for use with a firestop or wall

thimble.

Horizontal Top*

3" (76mm)*

Horizontal Side

2 " (51mm)

Horizontal Bottom

2" (51mm)

Vertical Vent

2" (51mm)

Termination

Cap

Wall Thimble 2 pieces

(10" (254mm)

Outer Diameter)

2” x 4” or 2” x 6”

6-7/8" (173mm)

dia. air intake

4" (102mm) dia. flue pipe

with spring spacer

Screws

(3 per

connection)

Screws

(4 per

connection)

CL

CL

39”

(991mm)

Min.

of hole

Using Fle

x System

Recommended Framed Opening Size

Vent Size

Framing Size

102mm x 175mm

254mm x 254mm