24

Regency Horizon™ HZ42STE Gas Fireplace

INSTALLATION

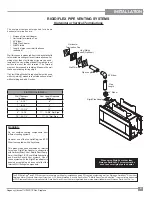

• Vent must be supported at offsets.

• Firestops are required at each fl oor level and

whenever passing through a wall.

• Maintain clearances to combustibles as listed in

the "Clearances" section.

•

Refer to the "Vent Restrictor Position" section for

details on how to change the vent restrictor from

Set 0 (factory setting) to Set 1 to Set 2 or Set 3 if

required.

Note: Must use optional fl ue adaptor when using

Rigid Pipe (Part # 510-994).

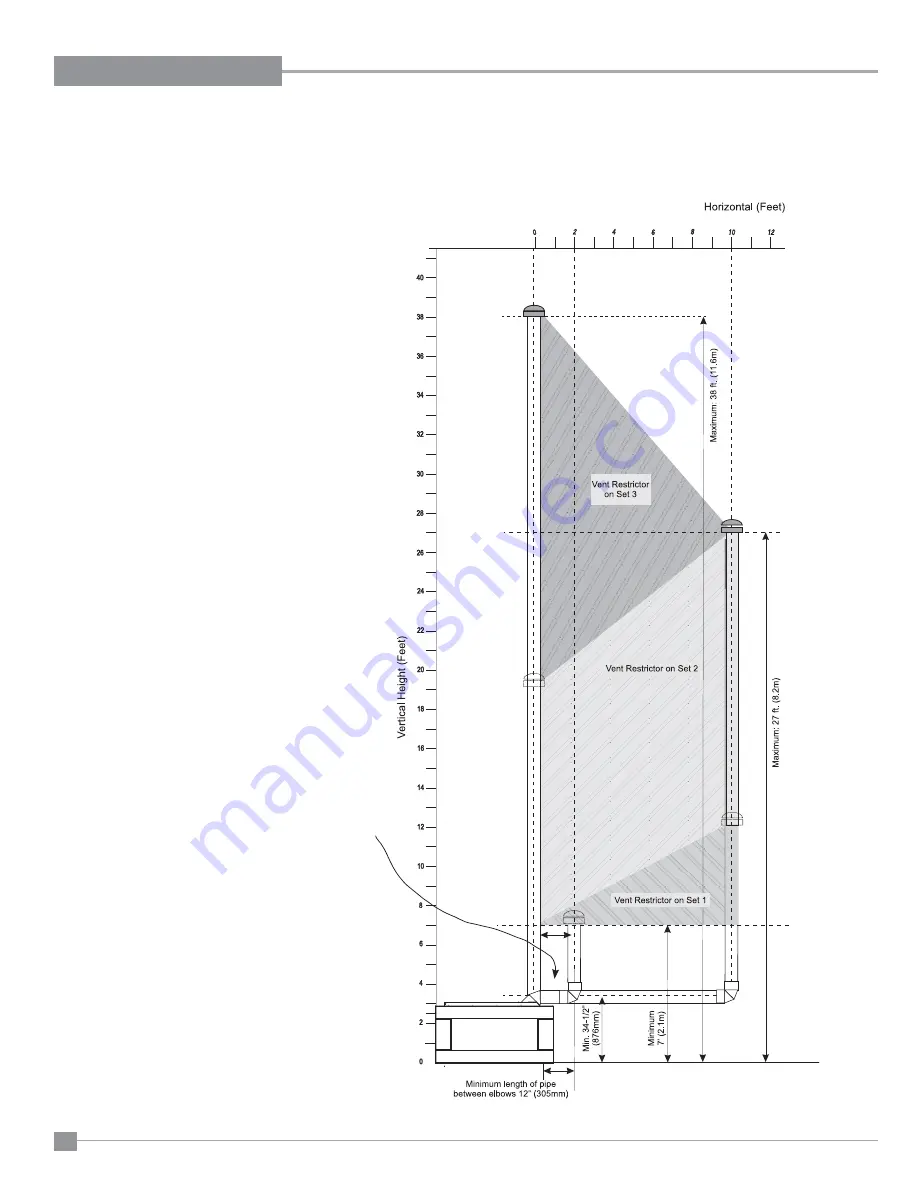

VENTING ARRANGEMENT FOR VERTICAL TERMINATIONS

The shaded area in the diagram shows all allowable combinations of straight vertical and offset to vertical terminations, using one 90

o

elbows, with

Rigid

Pipe Venting Systems

for Natural Gas. Two 45

o

elbows

equal to one 90

o

elbow. Maximum of two 45

o

elbows allowed.

Please note: min. 1 foot horizontal

required before 90

o

elbow.

(No back to back elbows.)