U1500E-11 Gas Fireplace | 7

Framing & Finishing

Important:

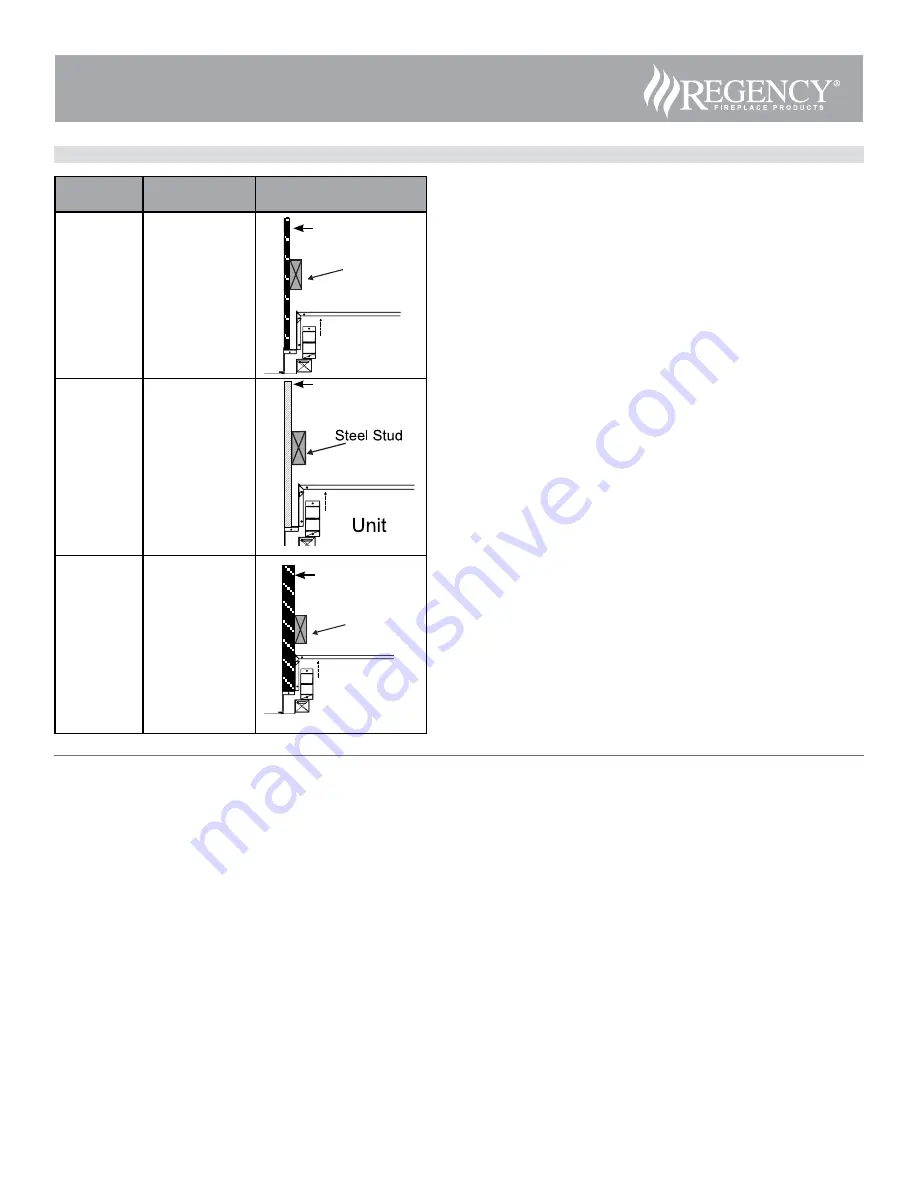

Determine the nailing strip position by determining the facing material being used.

Examples:

1/2" non-combustible wall board for clean finish =1" adjustment.

1/2" non-combustible wall board + 1/2" tile = 1" of finished material

= 1/2" adjustment.

Note:

Depending on the material used for finishing, the nailing strips must be set ac-

cordingly so that the finished material is always at the 1-1/2" edge of the flange.

Note : If material such as brick, stone, etc extends past the depth of 1-1/2" when

finishing around the faceplate ( Inner/Outer faceplate/Verona glass surround), the

minimum opening dimensions around the faceplate must be adhered to ensuring

for the removal of the faceplate and for the safe operation of this appliance. See

framing and finishing in this manual for details.

If only using the inner door trim to create a clean edge finish on all 4 sides,

non combustible material may extend beyond the 1 1/2" face to give you a

recessed look.

If the material below the appliance which only requires combustible material

extends beyond the 1 1/2" lip, ( ie: a hearth in front of the appliance) non com-

bustible material must be used. Combustible material cannot extend beyond

the bottom lip of the fireplace.

If using the finishing trim for clean face design, the maximum allowable depth

is 1 1/2" .The finishing trim will not fit if it exceeds 1 1/2".

IMPORTANT

Regency Fireplace Products are designed, produced, tested and certified to the highest industry standards.

The finishing of the walls surrounding your Regency Horizon Fireplace is as critical as the installation itself.

The temperatures around linear gas fireplaces are typically higher than would be acceptable for combustible materials. Your Regency

Horizon Fireplace is no exception to this rule. Therefore, the units are specified with non-combustible required materials to specific

dimensions above and around the units. This is due to these areas reaching higher temperature levels than required/acceptable for a

combustible material. To obtain the best, most durable finish around your fireplace, this calls for a high level of care and attention to the

preparation and finish around this appliance, using only the highest quality materials, able to withstand the temperatures produced.

By following the installation instructions in the manual exactly, you will increase your chances of a damage free finish.

While every precaution is taken in providing the recommendations on preparation and finish, given the variations in paint quality, with

temperature limits and workmanship in application, Regency is unable to guarantee the life of the joint compounds, paint or any other

finish materials or workmanship applied to or used in any application surrounding the fireplace. This includes framing as well as finishing.

Over time natural convection from any fireplace can cause discoloration in the area directly above the appliance. Lower quality paints,

under-prepared finishes, poor applications, and any framing discrepancies or in the installation can cause this discoloration process to

be expedited.

Discoloration is not the responsibility of Regency Fireplace Products. This is out of the control of Regency Fireplace Products Ltd.,

therefore not covered under any part of the warranty policy.

While discoloration is not the responsibility of Regency Fireplace Products, we believe careful attention to the recommendations provided

here will result in an aesthetically pleasing result free of issues outlined above.

U1500E-11 Gas Fireplace

Finished

Material

Nailing Strip

Position

1/2"

(13mm)

1"

(25mm)

1"

(25mm)

1/2"

(13mm)

1-1/2"

(38mm)

0" (flush)

Unit

Steel Stud

Unit

Steel Stud

Finished material

Finished material

Finished material