38

|

Regency

®

U39E-11 ULTIMATE™ Freestanding Gas Stove

installation

10.15.18

919-939

E

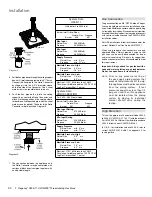

6 Place Front Right Log E on the two pins as shown.

Cutout

Notch

F

E

A

7. Place the notch in Center Log F over

Log E and across the cut-out on Log A.

Notch

A

G

E

F

8. Position notch in Front Right Log G on Log F and push the

bottom right edge against the bracket on the burner tray.

E

Bracket

The bottom right edge of Log G must sit

snugly against the bracket

Side

View

G

9. Take the Embaglow, (steel wool like material) lightly separate

it and set a small amount over the visible burner ports in

front and between the front left log and the log under the

“Y” log, indicated in the picture.

IMPORTANT

: DO NOT compress this material down on the

burner ports.

Embaglow

10. Next, take the white Platinum Ember material (provided)

and gently separate the layers until you have a fi ne layer

to place onto the Embaglow (steel wool type media).

Platinum Embers