U37-1 Regency

®

ULTIMATE Rear Vent Direct Vent Freestanding Gas Stove

9

INSTALLATION

COMBUSTION AND

VENTILATION AIR

The combustion air from this appliance is drawn

from outside the building through the outer fl ue.

Extra provision for combustion air inside the

room is not required.

VENTING

The Regency

®

Direct Vent System (Horizontal

Termination Kit (640-944) and the Vertical

Termination with the Co-linear Flex System in

combination with the ULTIMATE Direct Vent-

Rear Freestanding Gas Stoves (U37-NG1 and

U37-LP1) have been tested and listed as direct

vent heater systems by Warnock Hersey.

The Horiz. Termination Kit (640-944) includes

everything required for a straight through the

wall installation, or add a 45

o

elbow for a corner

installation. If a snorkel termination is required,

the Simpson Dura-Vent Direct Vent System

Model DVGS terminals are available.

INSTALLATION

CHECKLIST

1)

Locate your appliance. Refer to the following

sections:

a. Clearances to Combustibles

b. Locating your Ultimate Gas Stove

c. "Venting" to "Rigid Pipe Venting -

Vertical Terminations" sections.

2)

Install venting. See "Planning Your Venting

Installation" to "Vertical Termination with

Co-Linear Flex System" sections.

3)

Make gas connections. Refer to the "Gas

Connection" section.

Test the pilot. Must be as per diagram in the

"Maintenance Instructions" section.

4)

If necessary, convert from Natural Gas to

Propane. Refer to the "Conversion Kit from

NG to LPG" section.

5)

Installl standard and optional features. Refer

to the following sections where applicable:

a. Log Set Installation

b. Door Installation

c. Louver Installation

d.

Wall

Thermostat

e. Remote Control

6)

Final check. Refer to the "Final Check" sec-

tion.

Before leaving this unit with the customer, the

installer must ensure that the appliance is fi r-

ing correctly and

operation fully explained

to customer.

This includes:

1)

Clocking the appliance to ensure the correct

fi ring rate (rate noted on label) after burning

appliance for 15 minutes.

2)

If required, adjusting the primary air to ensure

that the fl ame does not carbon. First allow

the unit to burn for 15-20 min. to stabilize.

CAUTION: Any alteration to the product that

causes sooting or carboning that results

in damage is not the responsibility of the

manufacturer.

MANUFACTURED

MOBILE HOME

ADDITIONAL

REQUIREMENTS

1)

Ensure that structural members are not cut

or weakened during installation.

2)

Ensure proper grounding using the #8 ground

lug provided.

3)

Appliance must be anchored to the fl oor with

the supplied anchoring methods.

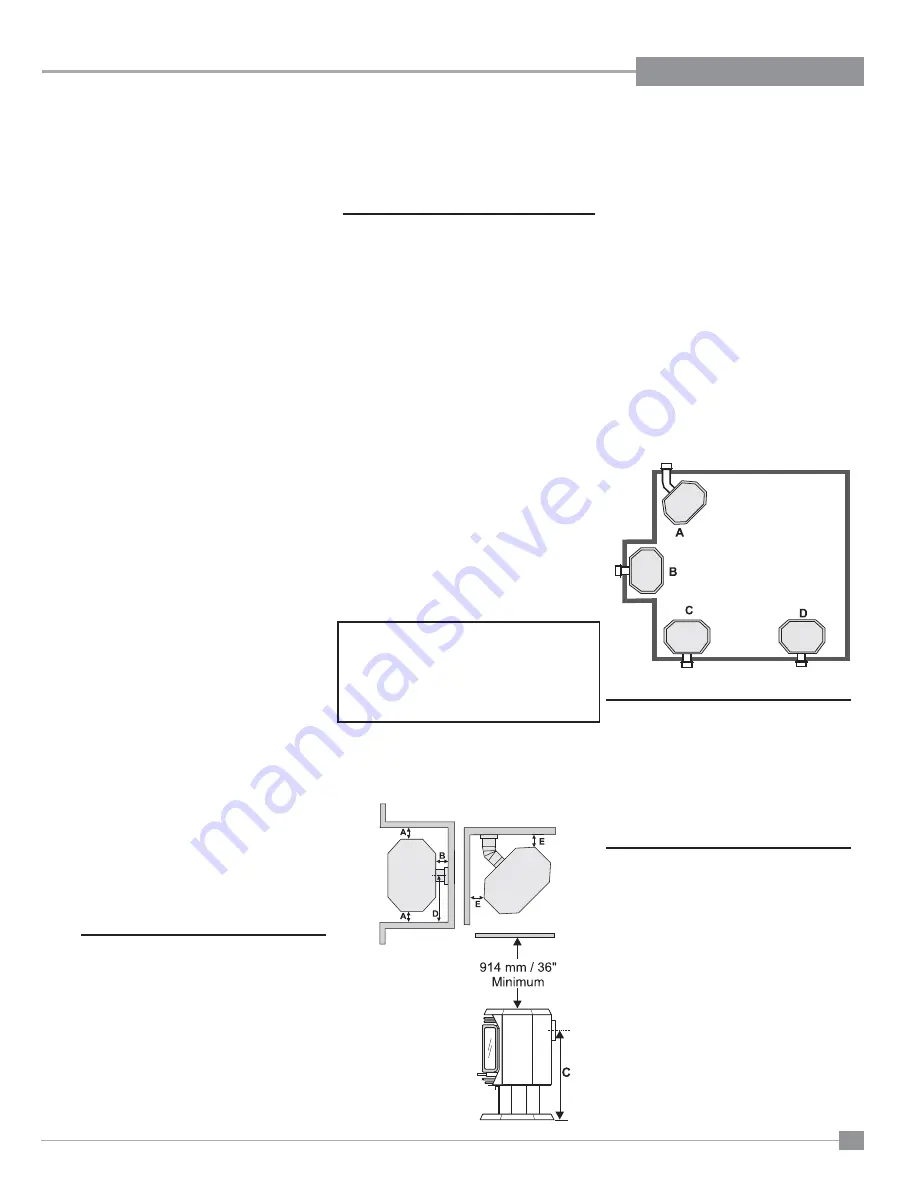

CLEARANCES TO

COMBUSTIBLES

The clearances listed are MINIMUM distances.

Measure the clearance to both the appliance and

the chimney connector.

The farthest distance is

correct if the two clearances do not coincide.

For example, if the appliance is set as indicated

in one of the diagrams but the connector is too

close, move the stove until the correct clearance

to the connector is obtained.

This appliance may be installed only with the

clearances as shown in the situations pictured.

Do not combine clearances from one type of

installation with another in order to achieve

closer clearances.

This unit can be installed on a solid combustible

surface like a wood fl oor. This unit can also be

installed directly on carpeting or vinyl when the

bottom pedestal cover plate (provided with unit)

is installed.

Use the minimum clearances shown in the dia-

grams below:

Clearances

A Side Wall to Unit

7-1/2" / 190 mm

B Back Wall to Unit

3" / 76 mm

E Side Wall to Unit

4-1/2" / 114 mm

Reference Dimensions

C Floor to Flue Centerline

25" / 635 mm

D SideWall to Flue Centerline20-1/2" / 521 mm

LOCATING YOUR

GAS STOVE

When selecting a location for your stove, ensure

that the clearances listed above are met as well

as ensuring that there is adequate accessibility

for servicing and proper operation.

For Vent Termination requirements, see the

"Exterior Vent Terminal Locations" section.

This appliance is Listed for bedroom installations

when used with a Listed Millivolt Thermostat.

Some areas may have further requirements,

check local codes before installation.

This appliance is Listed for Alcove installations,

maintain minimum Alcove clearances as follows,

minimum ceiling height of 66"(1.7m), minimum

width of 41"(1.0m) and a maximum depth of

36"(0.9m).

Minimum ceiling height

is 36" / 914 mm from

top of unit.

A) Cross

Corner

B)

Flush with Wall/Alcove

C) Flat on Wall Corner

D) Flat on Wall