28

BA 90M-P140M-P160M(D) 0802/dfe

6 Shipping

– Cool the unit.

– Switch off the unit, actuate the main switch, and unplug the power cord.

– Remove all hoses from the unit.

Before shipping the unit, evacuate the unit completely using the blow-out device (

→

Service).

Blow out the cooler as follows to avoid the danger of freezing (cooling hose collapse) at low temperatures:

1

Switch on the unit: Actuate the main switch and press the

“

ON/OFF

”

key.

2

Adjust the set-point value to 0 °C at the controller.

3

Ensure that the cooler’s solenoid valve is open.

4

Blow out the cooler using compressed air at a maximum pressure of 6 bar.

5

Switch off the unit by pressing the “ON/OFF” key, actuate the main switch and unplug the power cord.

6

Do not tip the unit. Heat transfer fluid remaining in the unit could run out, soaking the insulation.

7

Use the original packing material. Mark the top clearly.

6.1 Disposal

1

Evacuate the unit completely and dispose of in accordance with local regulations.

2

The unit may also be sent back to Regloplas in Switzerland for disposal.

7

Optional equipment

7.1

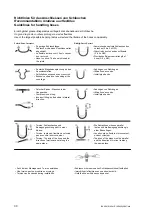

Consumer evacuation by means of suction (RT50 control system only)

The heat transfer fluid is suctioned through the consumer by means of underpressure created by reversing the pump’s

direction of rotation.

In suction mode, the heat transfer fluid in the consumer will enter the sewage system through the cooling water out-

let.

Pressing the Suction key initiates the suction program, in which the consumer connected to the unit is evacuated via

the pump by means of suction.

Suction is possible only when the temperature of the heat transfer fluid is below the programmed run-out temperature

value (RT50 Programming Instructions, Section 7.2, P 4.3). If this is not the case, the unit will first cool the fluid to this

value.

The suction program can be interrupted by pressing the “ON/OFF” key.

Pressing the key again (wait until

OFF

shows in the display) returns the unit to normal operation.

7.2 Switching from indirect to direct cooling in Models P140M and P160M(D)

To increase the cooling capacity at temperatures below 80 °C, the unit switches to direct cooling at this temperature.

In direct cooling, the heat exchanger is not in operation, and the cooling water mixes with the circulating water in the

temperature control circuit.

(Model 90M is available only with direct cooling.)

7.3 Flow rate measurement with the RT50 control system

Using the

key, go to “Display actual value”. Press the same key once again to display the flow rate. Return to the

operating level by pressing the same key one more time.