5

│

REGULUS - DUO N P Thermal Stores - www.regulus.eu

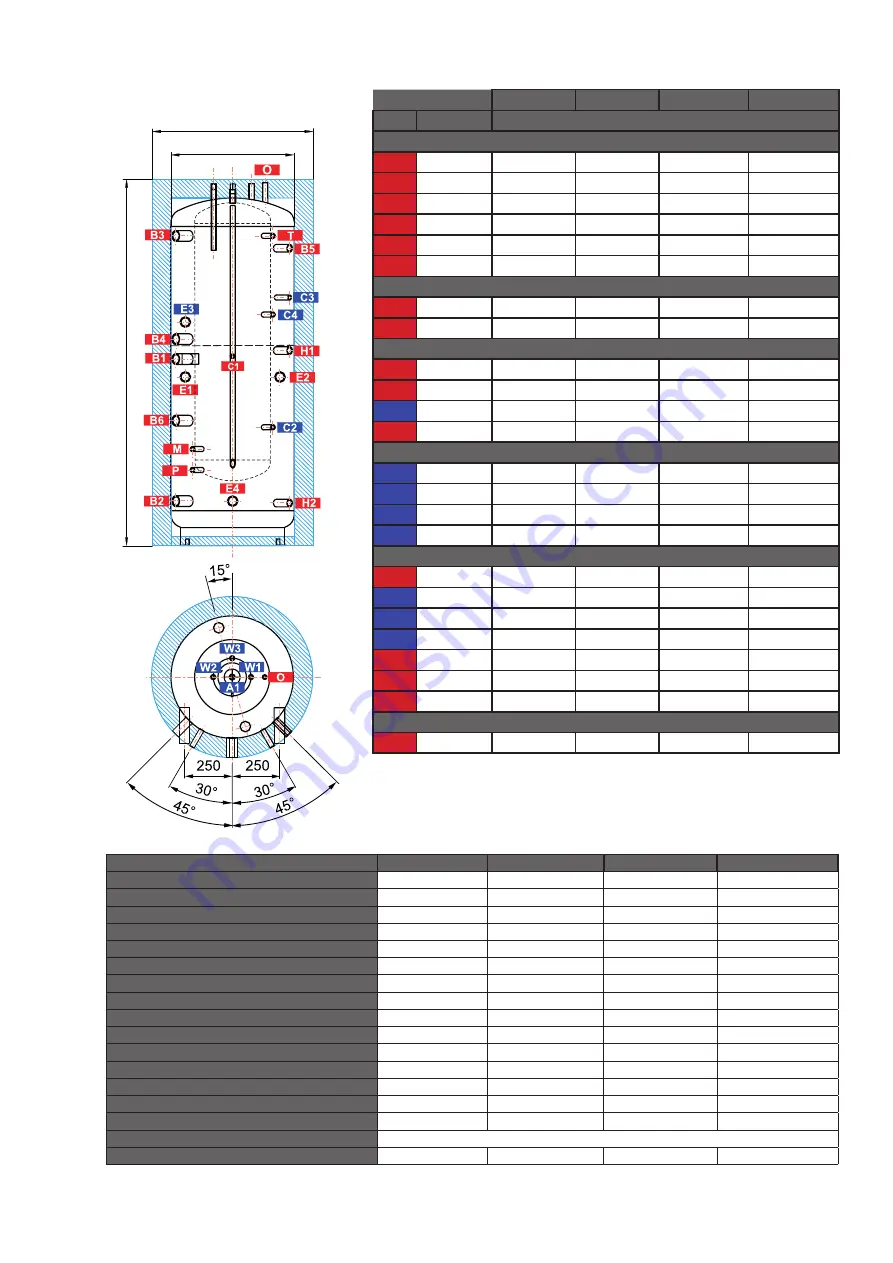

Regulus DUO 600/200 N P, 750/200 N P, 1000/200N P, 1700/200 N P Thermal Stores

DUO 600/200 N P DUO 750/200 N P DUO 1000/200 N P DUO 1700/200 N P

pos. connection

height [mm]

Heat sources

B1

G 6/4"F

985

960

1115

1150

B2

G 6/4“F

235

255

300

335

B3

G 6/4"F

1635

1655

1700

1675

B4

G 6/4"F

1090

1065

1220

1255

B5

G 1"F

1570

1590

1635

1610

B6

G 6/4"F

660

635

785

820

Heating system

H1

G 1"F

1030

1005

1160

1195

H2

G 1"F

225

245

290

325

Electric heating elements

E1

G 6/4"F

890

865

1020

1055

E2

G 6/4"F

890

865

1020

1055

E3

G 6/4"F

1180

1055

1310

1295

E4

G 6/4"F

235

255

300

335

DHW heating

W1

G 1"M

1935

1980

2080

2080

W2

G 1"M

1935

1980

2080

2080

W3

G 1“M

1935

1980

2080

2080

A1

G 1“F

1935

1980

1980

1980

Control and safety

C1

G 1/2"F

1000

975

1130

1165

C2

G 1/2"F

625

615

740

775

C3

G 1/2"F

1310

1285

1440

1425

C4

G 1/2"F

1220

1195

1350

1335

T

G 1/2"F

1635

1655

1700

1675

M

G 1/2"F

510

510

510

510

P

G 1/2"F

400

400

400

400

Air release

O

G 1/2"F

1915

1960

2060

2060

DUO 600/200 N P DUO 750/200 N P DUO 1000/200 N P DUO 1700/200 N P

Code - tank

19147

19141

19143

19137

Code - insulation

19330

19333

19334

19354

Standing loss

102 W

118 W

130 W

175 W

Total tank volume

559 l

757 l

903 l

1682 l

Fluid volume in tank

385 l

583 l

729 l

1508 l

Volume of immersed DHW tank

174 l

174 l

174 l

174 l

Max. working temperature in tank

95 °C

95 °C

95 °C

95 °C

Max. working temperature in DHW tank

95 °C

95 °C

95 °C

95 °C

Max. working pressure in tank

3 bar

3 bar

3 bar

3 bar

Max. working pressure in DHW tank

6 bar

6 bar

6 bar

6 bar

Tank diameter

650 mm

750 mm

800 mm

1100 mm

Tank diameter with insulation

850 mm

950 mm

1000 mm

1300 mm

Tank overall height

1935 mm

1980 mm

2080 mm

2080 mm

Tipping height without insulation

1970 mm

2040 mm

2120 mm

2200 mm

Empty weight

126 kg

147 kg

167 kg

225 kg

Electric heating element

type ETT-C, F, M, P

Number and max. length of heating elements

4 x 500 mm

4 x 650 mm

4 x 720 mm

4 x 1050 mm

Průměr nádrže s izolací

Průměr nádrže

Celková výška

Tank diameter with insulation

Tank diameter

Overall height