PAGE 102

OPERATOR’S MANUAL ULTRA GUIDANCE PSR ISO

CHAPTER

PSR TAC

7.2.

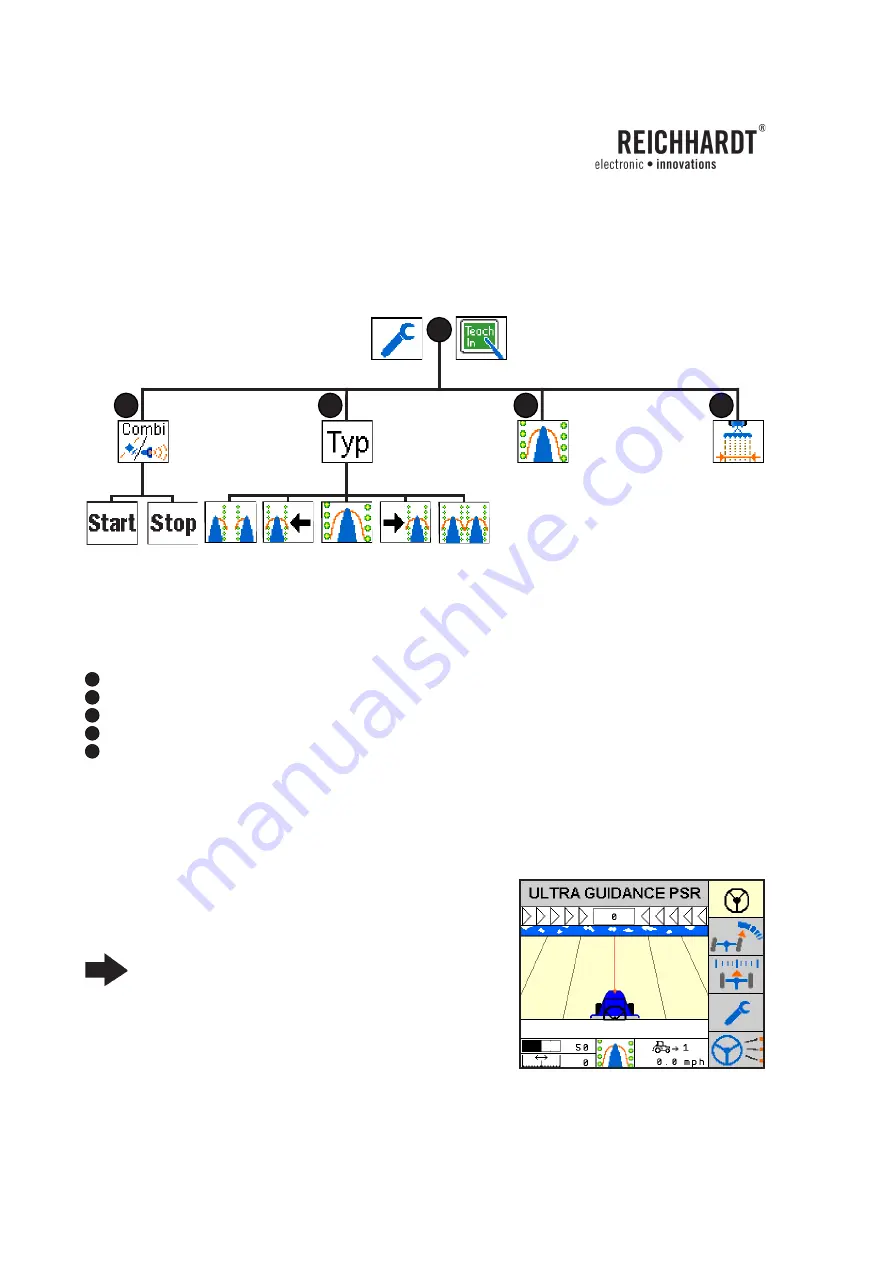

Menu structure PSR TAC

A

= Main menu PSR TAC

B

= TAC sensor calibration

C

= Set working width

D

= Joint use of PSR TAC – PSR SKY

E

= Types of TAC sensors

7.3.

Main screen PSR TAC

Display:

Main screen

Set drive mode according to the adjoined picture (see chapter

4.5.).

Advice!

In drive mode PSR TAC the distance shows a

slight deviation of the vehicle to the left or right of the

guide line.

Picture 178:

Main screen PSR TAC

Picture 177:

Menu structure PSR TAC

A

D

E

B

C