Original Instructions

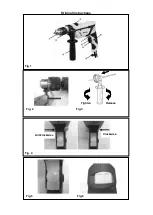

Mark off the centre of the hole using a centre punch.

Use a suitable lubricant for the material you are working on.

Begin drilling at a very low speed to prevent the bit from slipping off the starting point.

Always clamp sheet metal. Support thin metal with a block of wood to avoid distorting it.

Drilling masonry

For maximum performance, use high quality carbide-tipped masonry drill bits when drilling

holes in brick, tile, concrete etc.

Use the drilling setting initially then revert to the hammer action once the holes are

established.

Apply light pressure and medium speed for best results in brick.

Apply additional pressure and high speed for hard materials such as concrete.

When drilling holes in tile, practice on a scrap piece to determine the best speed and

pressure.

NOTE:

Reverse rotation during impact drilling may damage the drill and drill bit.

5. SERVICE & MAINTENANCE

Always disconnect the device before performing any adjustment or

maintenance operation. If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent in order to avoid a hazard.

Disconnect from the power supply immediately if the supply cord is damaged.

Take care not to expose this tool to the rain.

Cleaning

Avoid using solvents when cleaning plastic parts. Most plastic parts are susceptible to

damage from various types of commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust, etc.

Lubrication