8

20 min.

Cleaner

Cle

an

er

Cle

an

er

Cleaning and Maintenance

Proceed as follows:

Remove the PUR cartridge from the

applicator.

Unscrew the nozzle adapter from

the warm glue cartridge.

Use a pointed tool to open the outlet of

the PURcleaner cartridge.

Screw the nozzle adapter on the

screw thread of the cleaner cartridge.

Insert the cleaner cartridge in the

applicator. Please ask the glue

producer for the cleaning agent

suited for the glue used by you.

Allow about 20 minutes for the

applicator to warm up the cleaner.

Flush the nozzle adapter with

cleaner until you see cleaning

agent come out steadily.

Remove the cleaner cartridge from the applicator and

unscrew the nozzle adapter and nozzle from the cleaner

cartridge while it is still warm.

Caution: Hot cleaning agent may flow out!

Allow the cleaner cartridge to cool and keep it for further

use.

Never fill soiled glue into the melting tank. If you observe

all advices given in the operating manual, the glue

applicator does normally not need cleaning. The

nonreactive glue contained in the applicator will remelt

and can be used for glueing again.

The working temperature of the respective glue may be

taken from the technical datasheet which can be

procured from the producer of the glue. This temperature

must not be exceeded, otherwise the glue may coke in

the glue applicator. Hotmelts on a polyamide basis are

particularly sensitive. If the glue has coked, the applicator

should be cleaned.

Never clean the applicator with solvent, benzine,

benzene, toluene, acetone, turpentine, etc. risk of

explosion!

When reactive PUR hotmelt glues are used, the adapter

and the nozzles must be flushed thoroughly. For this, use

a special cleaning agent in 310ml cartridges. Please ask

your glue supplier for the cleaning agent suited for the

hotmelt used by you.

If the applicator is used very often, we recommend to

have it maintained regularly. For this, fix a date with our

service department.

Cleaning the Nozzle/Nozzle

Adapter after having

applied PUR HotMelt Cartridges

(TR 700 / 70 / 80)

Warning: risk of burns!

For your own safety you are advised to

wear protective gloves and safety goggles

when replacing nozzles.

When the applicator will not be used for a longer time,

we recommend that you clean the nozzle/the adapter

because reactive PUR hotmelts may harden within a

short time and cannot melt any more.

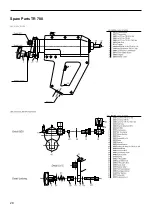

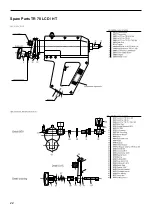

Summary of Contents for TR 50.4 25

Page 16: ...1 4 Spare Parts TR 50 4...

Page 18: ...1 6 Spare Parts TR 55 LCD HT...

Page 20: ...1 8 Spare Parts TR 60 LCD HT...

Page 22: ...20 Spare Parts TR 700...

Page 24: ...22 Spare Parts TR 70 LCD HT...

Page 26: ...24 Spare Parts TR 80 LCD HT...