2

DRAIN VALVE OPTION

(According to Local

Plumbing Code.) 3/4 inch rigid copper piping must be

installed from the steam generator location to a drain.

Ensure that all water is able to drain from all sections

of the drain line at all times. Ask dealer for automatic

drain details.

ELECTRICAL - WATTS, WIRE AND FUSE SIZES

According to local electrical code. Use copper wire only.

Must be installed by qualified Electrician.

STEAM GENERATOR:

JR-3

JR-4

WATTS

6,000

9,000

Hz

60

60

Phase

1

1

208 VOLTS

Fuse/Breaker Size

40 Amp

60 Amp

Copper Wire - Supply

#8 AWG

#6 AWG

Copper Wire - Switch

#22 AWG

#22 AWG

240 VOLTS

Fuse/Breaker Size

40 Amp

50 Amp

Copper Wire - Supply

#8 AWG

#6 AWG

Copper Wire - Switch

#22 AWG

#22 AWG

Check to ensure that the supply voltage (either 208V or

240V) is compatible with the voltage listed on the

steam generator identification label (below water

supply). The fuses or circuit breaker must be of

adequate size to carry the necessary amperage to

operate the steam generator.

Select a convenient location in the steam room, within

20 feet of the steam generator, (5 feet up from the

finished floor,

away from the area above the steam

nozzles

) to install the Quick Touch Timer (found in the

appliance electrical box) and cord set packaged with

steam unit. Cut a 7/8 inch hole in the wall material and

pass the female end of the cord set through the wall for

final installation.

OR

, the Time and Temperature

Control with remote may be installed

(purchased

separately)

. ASK DEALER FOR DETAILS.

There is one copper “2 wire and ground power cable”,

class 1 wire, and one factory supplied “25 foot control

wire”, class 2 wire, to be run to the steam generator:

a -

Run a copper power supply cable, 2 wire and

ground of adequate gauge to carry the

necessary amperage from the fuse or circuit

breaker to the steam generator location.

b -

Run the factory supplied “25 ft cord set” from the

steam generator location to the Timer Control

location. Leave sufficient length at each end of

cord set for the final installation connections.

SEE

“CAUTION 8, 9 and 10

".

THE ELECTRICAL

”SUPPLY”

FOR THE STEAM

GENERATOR

CAN NOT

BE SWITCHED DIRECTLY

BY THE TIMER CONTROL SUPPLIED WITH THE

STEAM GENERATOR.

Use Copper Supply Wire Only

.

The copper power supply cable must run directly, from

the fuse or circuit breaker to the steam generator. The

factory supplied cord set must be run directly from the

steam generator to the Timer Control. The Timer

Control activates a contactor in the steam generator,

through the class 2 voltage circuitry.

STEAM PIPING TO BATH OR SHOWER

(½ inch rigid

copper pipe required) Install two ½ inch rigid copper pipes

(maximum 20 feet each) from the steam generator to where

they will enter the steam bath area, in a location where the

steam will not burn anyone. Insulate the steam pipes for

maximum efficiency. WARNING STEAM NOZZLE IS HOT

The end of the steam pipes in the steam room should each

have a ½ inch female pipe thread fitting that is attached to

something solid, (example: a “wingback 90 elbow” used to

rough in a shower head). For steam nozzle location

purposes during rough-in, install ½ inch iron pipe nipples

into the two female fittings (hand tight) so they will protrude

through the wall into the steam room. After the finished

walls are in place, the iron nipples are to be replaced by

brass nipples the appropriate length. See

“FINAL

INSTALLATION STEAM PIPING”

and

Fig, 3

.

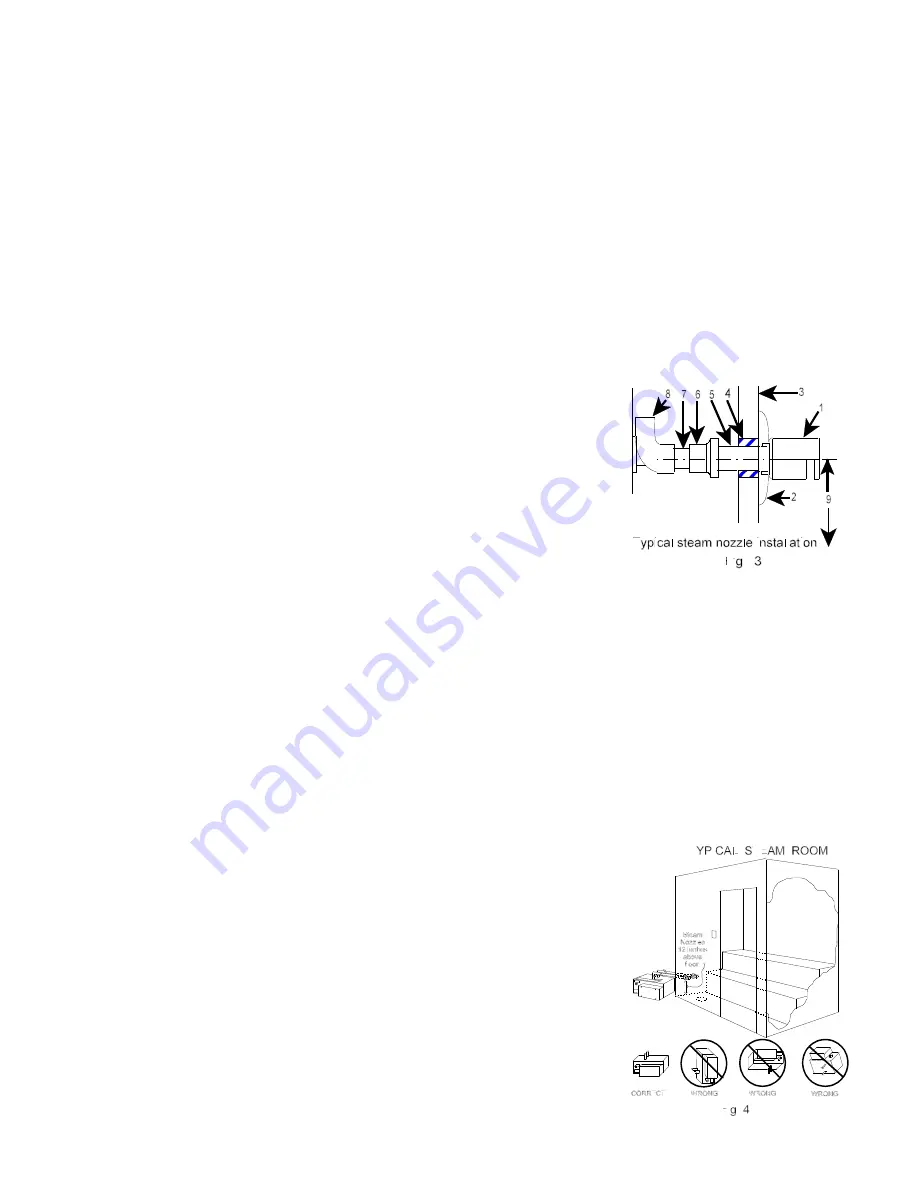

1 - Steam Nozzle

2 - Escutcheon

3 - Finished Wall

4 - Sealer (silicone)

5 - ½” Brass Nipple

6 - ½” C x FIP. Adapter

7 - ½” Rigid Copper Pipe

8 - ½” CxC Wing Elbow

9 - 12" from steam pipe

to steam room floor.

Warning: Steam Nozzle is HOT

In a shower or steam room the centre of the brass nipples

and steam nozzles must be 12 inches above the finished

floor, and in a location away from the users pathways,

where the steam will not burn anyone, preferably on the

same wall as the shower head. See

“Figure 4"

.

If the steam nozzles are installed too low, the steam will

strike the floor (may cause damage to tile grout) and

condense into water before it can heat and steam the room.

Installing the steam nozzles correctly, in the lower part of

the room ensures a more even distribution of the heat and

steam.

It is not recommended

to place the steam

nozzles under a bench,

as there is a distinct

possibility that someone

sitting on the bench

could inadvertently put

their feet underneath it

and be burned. When

the steam nozzles are

under a bench it is

sometimes impossible

for the heat and steam

condensate to circulate

throughout the room.