Forest Grove, Oregon 97116 USA

(503) 357-5607 or (800) 382-3765

General

Specifications

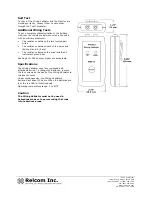

FBT-5

Fieldbus Wiring

Validator

Fieldbus wiring can be tested using the FBT-5 Wiring

Validator. It puts a DC voltage and fieldbus signals on

the wire pair. A Relcom Fieldbus Monitor, FBT-3, is

used to test the DC voltage, signal levels and noise

on the wiring. These tests can be performed on

existing instrumentation wiring, newly installed

fieldbus cable, or a fieldbus wiring system with wiring

blocks and terminators already installed.

Connection

Connect the FBT-5 using the clip leads at one end of

the cable. Connect the Terminator using the clip

leads to the other end of the cable. Connect the FBT-

3 to the Terminator. The red clips should connect to

the positive Fieldbus wire and the black clips to the

negative Fieldbus wire. If the wires are reversed, the

Monitor will not turn on.

Operation

The Wiring Validator has a push-button Power switch

that turns it on or off. If the Wiring Validator is

turned on with a single click of the Power button, it

stays on for about 5 minutes and then turns itself off

to save battery power. If the Wiring Validator needs

to be on indefinitely, push and hold down the Power

button for about 3 seconds.

The green light shows that the Wiring Validator is on.

•

If the green light blinks rapidly (about three

times per second) the Wiring Validator or the

Monitor is not attached to the wire pair being

tested or the connection is backwards.

•

If the green light blinks slowly (about once a

second) there is a good connection to the wire

pair, the Wiring Validator is in the battery save

mode and will automatically power down in five

minutes.

•

If the green indicator light is on continuously

there is a good connection and the Wiring

Validator will stay on until it is turned off.

When the Wiring Validator is turned on, the Monitor

powers up and shows the following readings.

•

Voltage should be between 9 and 10 Volts

•

Push the Monitor's mode button once to get the

LAS function. The LAS signal level reading should

say "OK" and show the signal level.

Signal Level (mV)

Wire Condition

350 or more

Excellent

200-350

Good

150-200

Marginal

150 or less

Not Good

•

Push the Monitor's mode button three time to

get the NOISE AVerage function. The reading

should say "OK" and show a noise reading.

Noise Level (mV)

Wire Condition

25 or less

Excellent

25-50

Good

50-75

Marginal

75 or more

Not Good

Wire System Testing

A fieldbus wire system with two terminators and

other wiring blocks installed can be tested before

devices are connected. This is done the same way as

the wire testing described above. The only difference

is that the Test Terminator is not used.

Note: The wiring system cannot have fieldbus devices

attached to it during the test. The Wiring Validator

can not power the fieldbus devices and its signal

generator will interfere with any data transmission

that the fieldbus devices might initiate.

If the wiring system has the two terminators required

for fieldbus operation, the wiring system test will

have results comparable to the testing the wire by

itself. If, however, not enough terminators or too

many terminators have been installed, the measured

signal levels will be different. The chart below shows

the relative changes:

Terminators

LAS Signal (mV)

0

999

1

961

2 (correct number)

760

3

637

Error Conditions

If the outputs of the Wiring Validator are shorted, the

red Low Battery light blinks on and off. (As the Wire

Validator is attached to wires, the Low Battery

indicator may blink on momentarily). If the battery is

low, the red light is on continuously.