411

3. Verify that jumper J8 is properly positioned for your reference signal.

4. Apply AC input power and then press the Start button.

WARNING

ADJUSTMENT OF THE PROCESS INTERFACE BIAS POTENTIOMETER

COULD RESULT IN ZERO SPEED OPERATION OF THE CONTROLLER. THE

DRIVE IS INTENDED TO OPERATE AT A PREDETERMINED MINIMUM SPEED

UNLESS DISCONNECTED FROM THE POWER SOURCE. IF THE APPLICA

TION REQUIRES ZERO SPEED OPERATION WITHOUT SUCH DISCONNEC

TION, THE USER IS RESPONSIBLE FOR ASSURING SAFE CONDITIONS FOR

OPERATING PERSONNEL BY PROVIDING SUITABLE GUARDS, AUDIBLE OR

VISUAL ALARMS, OR OTHER DEVICES. FAILURE TO OBSERVE THIS PRE

CAUTION COULD RESULT IN BODILY INJURY.

5. Command minimum reference from your process control unit and

adjust PI BIAS to the desired minimum operating speed or torque.

6. Increase the process control reference signal to maximum and

adjust PI GAIN to the desired maximum operating speed or torque.

It may be necessary to repeat Steps 5 and 6 until proper maximum

and minimum speed or torque are attained because these

adjustments interact.

7. Press the Stop switch and wait for the motor to completely stop.

Adjust Rate Potentiometer(s)

With Speed Control models:

Adjust RATE 1 and RATE 2 for desired acceleration and deceleration

rates.

With Torque Control models:

1. Set J401 for Fast or Slow rate range:

NOTE:

F (Fast) setting is used for finer resolution at faster rates.

S(Slow) - 3.5 to 40 seconds

F(Fast) - 0.3 to 3.5 seconds

2. Adjust RATE 1 for the desired acceleration rate.

3. Adjust RATE 2 for the desired deceleration rate.

Summary of Contents for DC2 VS series

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

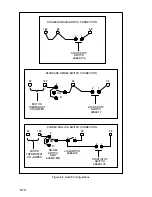

Page 31: ...3 16 419 519 TB2 Motor Mounted D C Tachometer Figure 3 8 D C Tachometer Connection...

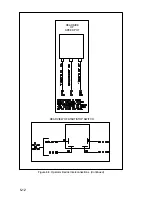

Page 48: ...5 6 Figure 5 1 Wiring Diagram of Basic Speed Controller 0 57210 30...

Page 49: ...5 7...

Page 51: ...5 9 J4...