19

CHANGING THE HIGH PRESSURE NOZZLE.

The high pressure nozzle fitted on the lance must

be changed from time to time, as this component

is subject to normal wear during use. Wear may

generally be detected by a drop in the working

pressure of the cleaner. To replace it, consult your

supplier and/or dealer for instructions.

OPERATIONS FOR USING ANTIFREEZE (fig.

17).

1)

Turn off the water supply (tap), disconnect the

hose and run the cleaner until it is completely

empty.

2)

Stop the water cleaner with the ON/OFF switch

in the “O” position (fig.10A).

3)

Prepare a container with the solution of an-

tifreeze.

4)

Immerse the tube in the container with the

anti-freeze solution.

5)

Start the water cleaner with the ON/OFF switch

in the “I” position.

6)

Start the cleaner and let it run until antifreeze

comes out through the lance.

7)

Suck up antifreeze with the detergent intake

system too.

8)

Switch off the cleaner and disconnect the electric

power by switching off the omnipolar switch,via

the omnipolar switch or by unplugging the plug

from the socket.

Anti-freeze may cause environmental pol-

lution. Always follow the instructions given

on the pack. (Dispose of carefully.)

CHECKING PUMP OIL LEVEL AND OIL CHAN-

GE.

From time to time check the oil level in the high

pressure pump by means of the sight glass (fig.

18A) or the dipstick (fig. 18B).

If the oil has a milky appearance, call the technical

service centre immediately.

Change the oil after the first 50 hours' work and

subsequently every 500 hours or once a year.

Proceed as follows:

1)

Unscrew the drain cap situated under the pump

(fig. 18C).

2)

Unscrew the cap with the dipstick (fig. 18).

3)

Let all the oil drain off into a container and

deliver it to an authorized oil collection and di-

sposal centre.

4)

Replace the drain screw and pour fresh oil

in through the filling cap on top (fig. 19A) until

it reaches the level indicated on the sight glass

(fig. 19B).

For water cleaners without oil drain bung,

contact our technical service centre for re-

placement.

Use only SAE 15 W40 oil.

CLEANING THE WATER FILTER

Clean the water intake filter regularly and free it

from any impurities (fig. 20).

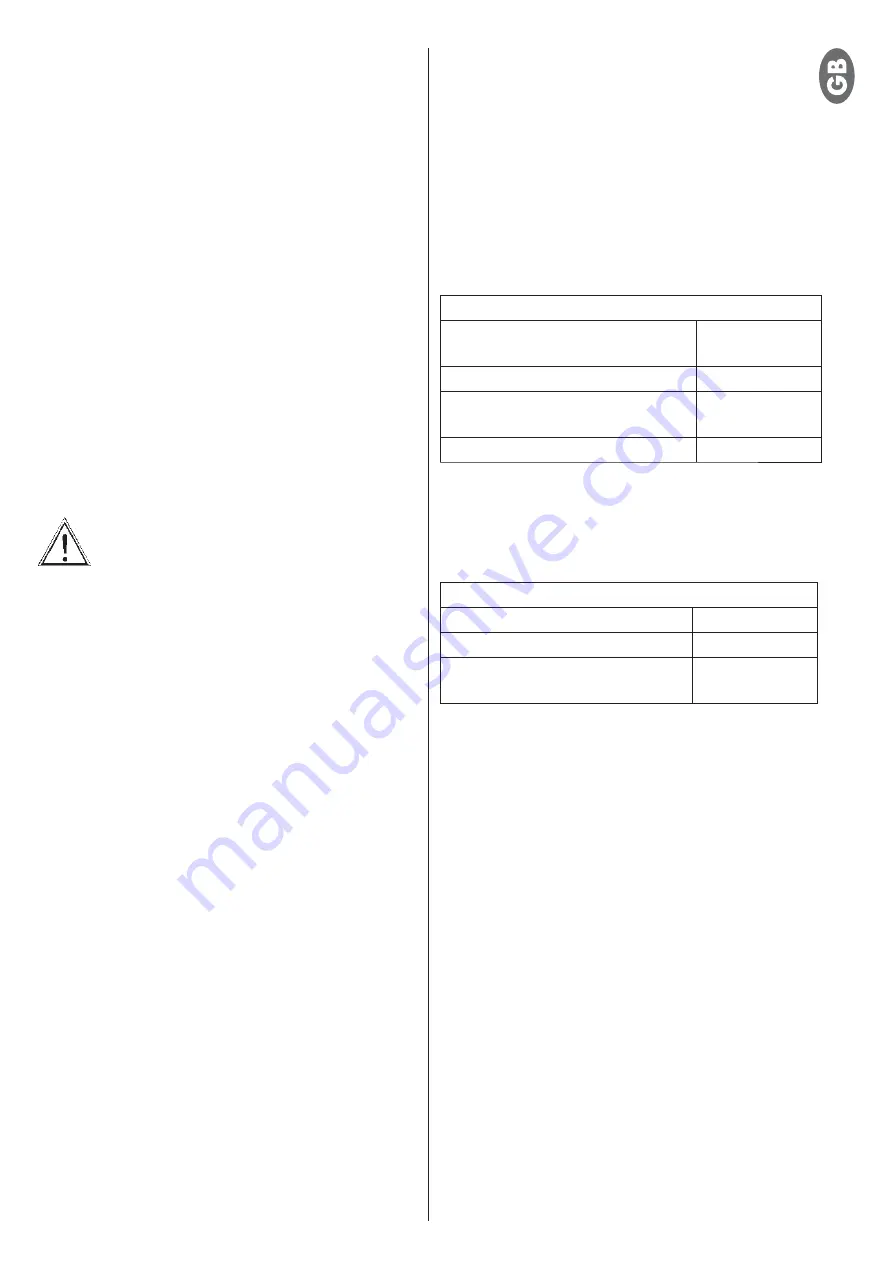

TABLE OF ROUTINE MAINTENANCE TO BE

PERFORMED BY THE USER.

Description of operations:

Check power cable - pipes -

high pressure connectors:

Each use

Ist oil change in H.P. pump:

A f t e r 5 0

Subsequent changes in H.P.

pump:

E v e r y 5 0 0

hours

Clean water filter

E v e r y 5 0

Description of operations:

Change seals on H.P. pump:

E v e r y 5 0 0

Change lanze nozzle:

E v e r y 2 0 0

Calibrate and check the safety

devices:

Once a year

TABLE OF EXTRAORDINARY MAINTENANCE

TO BE PERFORMED BY THE TECHNICAL

SERVICE CENTRE.

IMPORTANT:

These intervals refer to normal working condi-

tions. For heavy duty use decrease the interval

for each job.

For maintenance and/or repairs, use only

original spare parts which offer the grea-

test characteristics of quality and reliability.

Failure to use original spare parts absol-

ves the manufacturer from all liability and

transfers it to the person carrying out the

operation.

PERIODS OF INACTIVITY

If the machine is to remain inactive for a long

period, disconnect the supply sources, drain the

tank(s) of all the operating fluids and protect any

parts that could be damaged by the accumulation

of dust.

Grease the parts that could be damaged by drying

out, such as the supply hoses.

Summary of Contents for HDEm 662

Page 1: ...HDEm 662 HDEm 962 D EN CZ LV E P DK N SF GR HU ET LT SLO PL RU...

Page 3: ......

Page 85: ...84 i CE Fig 1 Fig 2 Fig 3 Fig 4 I IEC 60364 1 3 kW kW 1 72...

Page 86: ...85 25 250 bar 360 3600 PSI IEC 60364 1 3 mm 3 kW Total stop O 6 7 12 5...

Page 87: ...86 3 Kw 8 8 2 8 BAR 29 116 PSI 50 C 122 F 8C...

Page 88: ...87 3 Kw 3 Kw 1 8 1 2 10 3 4 5 8 Total stop O 13 A B 1 8 2 3 10 simbolo 4 Total stop...

Page 89: ...88 1 2 3 1 2 3 4 8 1 08 7 5 4 1 2 3 16 C...

Page 90: ...89 1 2 6 3 4 5 6 7 8 18 18 50 500 1 18C 2 18 3 4 19 6 W40 20 1 50 500 50 50 200...

Page 148: ...147...

Page 149: ...148 7RWDO 6WRS o p...

Page 150: ...149 c...

Page 151: ...150 o 7RWDO 6WRS o p o p 7RWDO 6WRS...

Page 152: ...151 PXOWLUHJ...

Page 153: ...152 o p o p 6...

Page 154: ...153...

Page 155: ......

Page 164: ...Notes...

Page 165: ......

Page 166: ......