English

EN

5.4. Overheating protection

The welding power source has a thermal overload trip

which operates if the temperature becomes too high,

interrupting the welding current and lighting a yellow

indicating lamp on the front of the power source.

The thermal overload trip resets automatically when

temperature has fallen.

5.5. MMA Welding

All welding parameter controls are placed on the

welding power source front panel.

Plug the power cord into a 230 V single phase mains

socketm macking sure that is earthed.

• Ref.1 Switch - on for the invertor ignition / “ON”

LED indicator.

• Ref. 2 LED indicating inverter blockage due to

overheating.

• Ref. 3 MMA / Lift Arc switcher for choosing the

mode of operating

Electrodes 1,60 mm (1/16”): minimum current 30A

maximum current 50A.

Electrodes 2,00 mm (5/64”): minimum current 40A

maximum current 70A.

Electrodes 2,50 mm (3/32”): minimum current 70A

maximum current 110A.

Electrodes 3,25 mm (1/8”): minimum current 110A

maximum current 140A.

Electrodes 4,00 mm (5/32”): minimum current 140A

maximum current 180A.

• Ref. 4 Ref. 5 Connect positive (+) and negative

(-) connectors to the earth cable and electrode

holder. Rutile electrodes need the electrode holder

be connected to negative pole (-) while basic

electrodes need the electrode holder connected

to positive pole (+). In any case, for each type

of electrode consult the instructions printed on

electrode box.

s

5.5.1. MMA welding current settings

WMEm 1

36

welding power source has an adjustable

welding current from 20 to 120 Amps.

WMEm 156

and

WMEm 157 Limited edition

welding

power source has an adjustable welding current from

20 to 140 Amps.

WMEm 176

and

WMEm177 Limited edition

welding

power source has an adjustable welding current from

20 to 160 Amps.

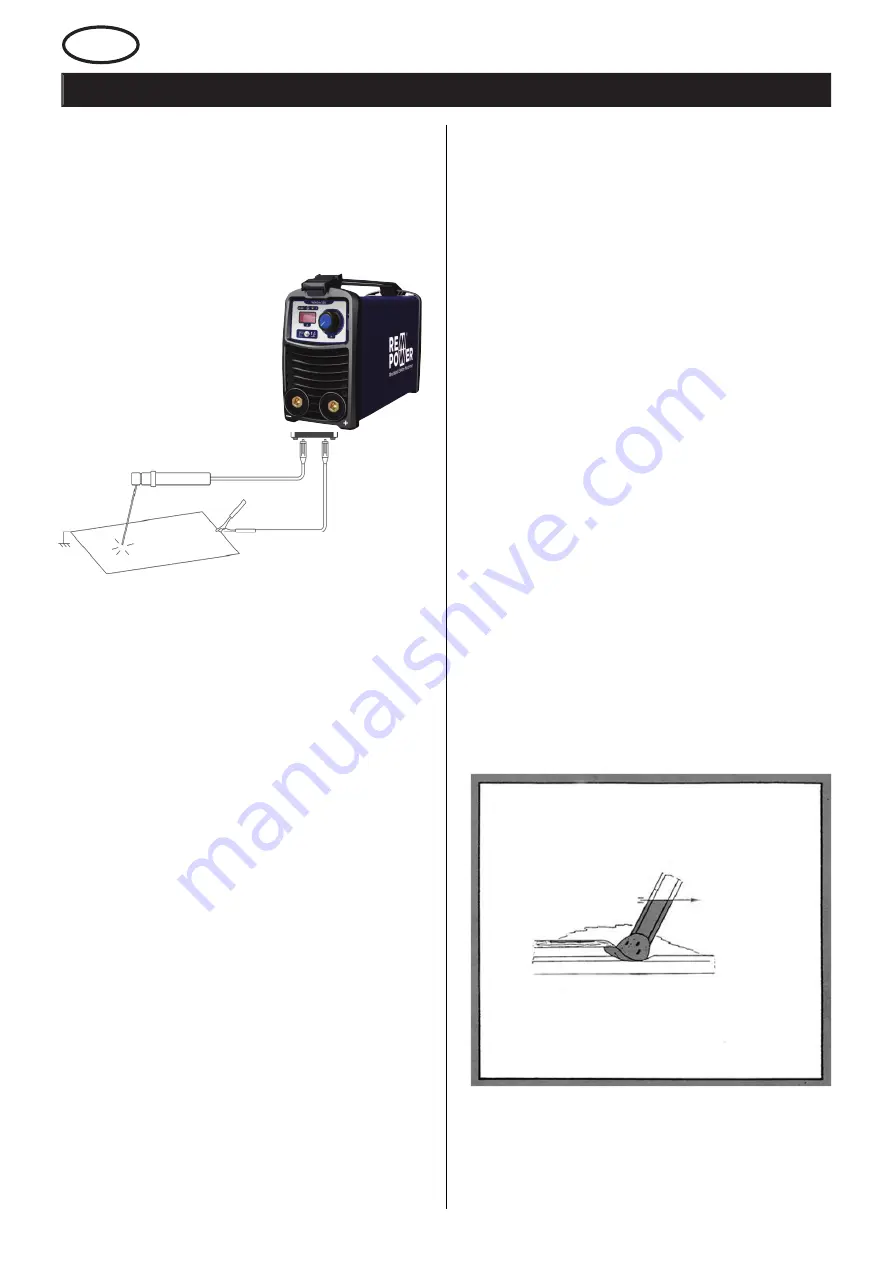

5.5.2. Striking the arc

Arc welding with coated electrodes is fusion procedure

that uses an electric arc as a source of heat. This is

formed between the extremities of coated electrode an

d a base material.

The heat developed by the arc melts the base material,

the rod and part of the coating. The remaining part of it

burns into smoke, creating an atmosphere that protects

the welding bead from the oxidizing action of the air.

The part of the coating that enters the welding bath

separates from the metal, moving to welding bath

where it forms the slag which contributes in protecting

against air.

The procedure can be done in all welding positions.

5.5.3. Manipulation of electrode

In MMA welding, there are three motions to being

matched in the end of electrode: the electrode moving

to the molten pool along axes; a small oscillation mayb

e necessary to achieve the desired width of the melt

pool; the electrode moving along welding way.

The operator can choose the manipulation of electrode

based on welding joint sharp, welding position,

electrode specification, welding current and operation

kill, etc.

CORE

COATING

SLAG

PENETRATION

WELDING DIRECTION

DEPOSIT LIFT BY THE WELD WELDING BEAD

BASE MATERIAL

11

Та

ше

в

-

Га

лв

ин

г

ОО

Д

www.tashev-galving.com

Summary of Contents for WMEm 136

Page 3: ...w w w t a s h e v g a l v i n g c o m...

Page 14: ...14 w w w t a s h e v g a l v i n g c o m...

Page 24: ...24 w w w t a s h e v g a l v i n g c o m...

Page 34: ...34 w w w t a s h e v g a l v i n g c o m...

Page 44: ...44 w w w t a s h e v g a l v i n g c o m...

Page 46: ...1 1 2 3 4 1 1 2002 96 EC 1 2 46 w w w t a s h e v g a l v i n g c o m...

Page 47: ...1 3 47 w w w t a s h e v g a l v i n g c o m...

Page 54: ...1 1 2 3 4 1 1 BG 2002 96 EC 1 2 54 w w w t a s h e v g a l v i n g c o m...

Page 55: ...1 2 BG 55 w w w t a s h e v g a l v i n g c o m...

Page 61: ...6 2 7 MCB 8 Elektro Maschinen Elektro Maschinen 9 BG 61 w w w t a s h e v g a l v i n g c o m...

Page 64: ...w w w t a s h e v g a l v i n g c o m...

Page 69: ...w w w t a s h e v g a l v i n g c o m...