19

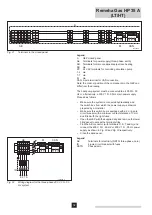

The following table indicates which jumpers need to be

FRQ¿JXUHGWRJHWKHUZLWKWKHDGGUHVVLQWKHGHYLFH

Unit

address

Jumper 1

position

Jumper 2

position

Jumper 3

position

Jumper 4

position

0

OFF

OFF

OFF

OFF

1

OFF

OFF

OFF

ON

2

OFF

OFF

ON

OFF

3

OFF

OFF

ON

ON

4

OFF

ON

OFF

OFF

5

OFF

ON

OFF

ON

6

OFF

ON

ON

OFF

7

OFF

ON

ON

ON

8

ON

OFF

OFF

OFF

9

ON

OFF

OFF

ON

10

ON

OFF

ON

OFF

11

ON

OFF

ON

ON

12

ON

ON

OFF

OFF

13

ON

ON

OFF

ON

14

ON

ON

ON

OFF

15

ON

ON

ON

ON

Table 04 Address table

6.4.5 LED signals for CAN-OT interface

If several faults occur simultaneously, the LED signalling

will display each fault in order of priority, until the problem is

resolved. The following list shows the order of priority. LED

status 0 has the highest priority.

LED on

No errors

OpenTherm and CAN-bus communication

working

/('ÀDVKHV

2x: No OpenTherm communication

3x: No CAN-bus communication

4x: Incorrect CAN-bus address settings

5x: Internal error

6x: CAN device is not supported

LED off

No voltage

Faulty

Table 05 LED signals for CAN-OT interface

6.4.6 Setting CAN-bus address on the Gas HP heat pump

In order to operate several heat pumps in a CAN-bus network

combined with CAN-OT interfaces, each heat pump must be

allocated a clear code. This can be done by setting parameter

40 in menu 5 for the heat pumps.

3DUDPHWHULVWKHSULQWHGFLUFXLWFRGHDQGLGHQWL¿HVWKH

device in the CAN network. Each heat pump is given a unique

code, independent of its position in the system. The value

that needs to be set for parameter 40 is the numerical code

assigned to the device and can vary from 0 to 478.

Set parameter 40 as follows:

1. Remove the front casing of the heat pump by unscrewing

and removing the screws.

2. Remove the cover plate of the electrical panel to be able to

access the set-up button.