unit operation with hose con-

nection

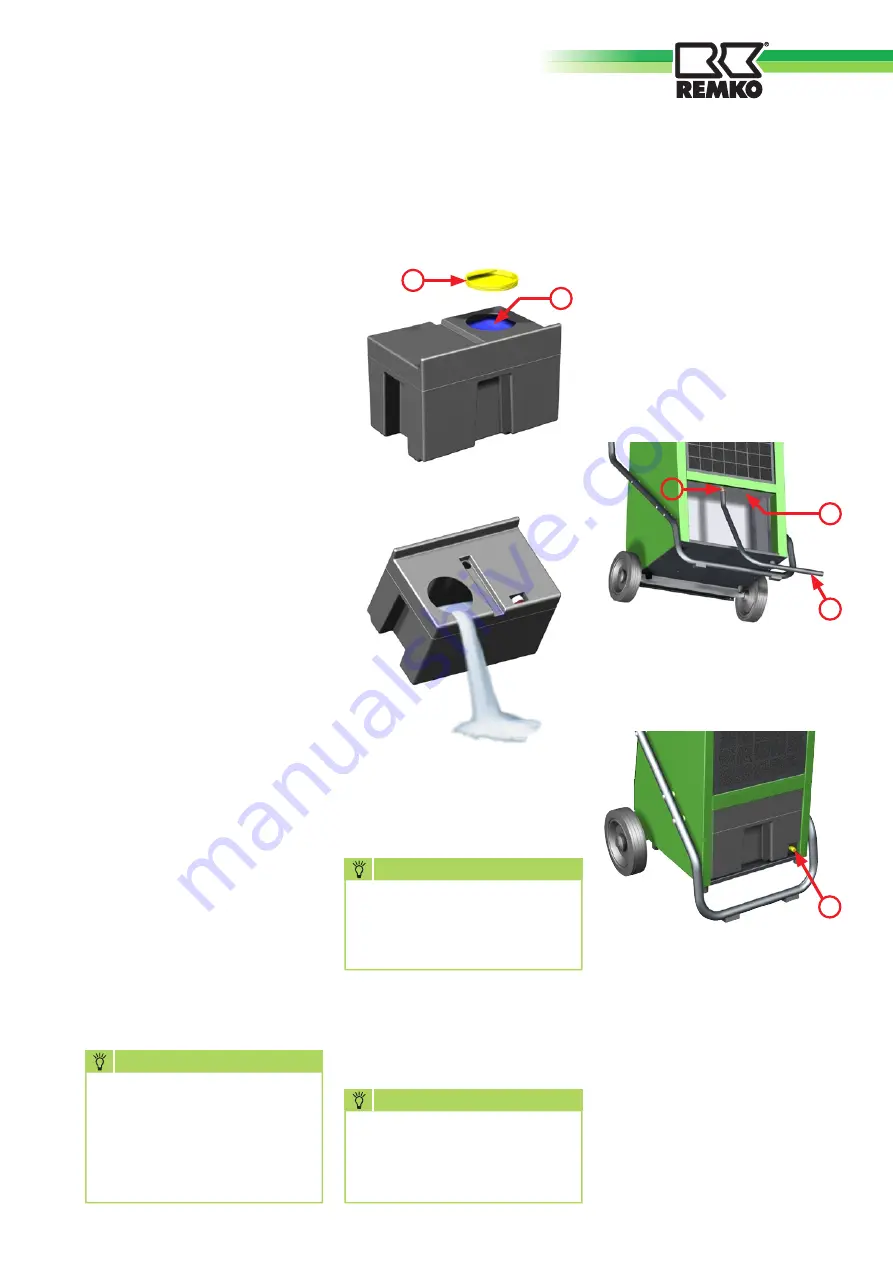

The condensate traps [K] of the

AMT 55 and 80-E are provided

with a connection [A].

A standard water hose [S] can be

connected to this connection after

removing the condensate con-

tainer.

The discharge hose [S] is not

contained in the factory scope of

supply.

With the AMT 40-E, connection of

the hose takes place directly to the

connection [D] of the condensate

container.

For unit operation, the condensate

container must always be placed

correctly in the AMT 40-E.

The condensate must preferably

be discharged to a lower located

outlet in unsupervised continuous

duty.

When using a collecting container

(container, bucket, etc.), the unit

must be installed at a raised level.

Further ideas, see next page!

3. Carefully place the container

outside the unit and open the

sealing cover [F] of the drain

opening [E].

4. Pour the water into a drain.

5. Close the drain opening [E]

again and carefully place the

emptied condensate container

back in the unit.

6. Switch on the unit again via the

operating switch [2].

Condensate

Depending on the air tempera-

ture and relative humidity, the

condensed water drips steadily or

only during the defrost phases in

the condensate trap or condensate

container.

Via a connection (not with AMT

40-E and 110-E), the condensate

flows into the condensate con-

tainer located below.

In the condensate container is a

float switch which interrupts dehu-

midification via a water stop switch

when the container is full.

For protection against unintention-

al shut-off with splashing water,

etc., this protective unit initially

switches off with a delay of 10

seconds. The unit switches off and

the yellow pilot light on the control

panel lights up.

The procedure for emptying the

condensate container is as follows:

1. Set operating switch [2] to posi-

tion “0” (Off).

Otherwise, the units AMT 55-E

and AMT 80-E would immedi-

ately restart after the container

is removed.

2. Remove the filled condensate

container.

For this purpose, lift the con-

tainer slightly via the recessed

handle and carefully pull out.

nOTE

The AMT 40-E units are only

functional with correctly

placed condensate container.

nOTE

After each emptying, the

condensate container including

float switch must be checked

for any damage, fouling, etc.

nOTE

Attention must be paid to

dripping condensate.

After switching off the unit,

the evaporator can continue to

defrost under the influence of

the ambient temperature.

D

E

F

A

S

K

11