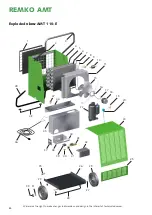

Cleaning the dust filter

Lightly push the guard grille

upwards, pull out and remove

downwards.

Remove the exposed dust filter.

If lightly soiled, the dust filter can

be cleaned by carefully blowing

out or by suction.

For heavy fouling, the filter can be

rinsed in a luke-warm (max. 40°C)

soap solution.

Subsequently rinse thoroughly

with clear water and allow to dry!

It must be ensured that the dust

filter is completely dry and undam-

aged prior to refitting.

The units must only be operated

with the dust filter fitted.

■

Observe the regular care and

maintenance intervals.

■

Depending on the particular

operating conditions, the units

must be inspected annually

as required, however, at least

once by an expert for their safe

working condition

■

Keep the units free of dust and

other deposits

■

Clean the devices only with a

dry or moistened cloth

■

Do not use a direct water jet

such as a high-pressure clean-

er, and so on!

■

Do not use caustic cleaning

agents or cleaning agents con-

taining solvents

■

Only use suitable cleaning

agent, even in case of heavy

soiling

For convenient transport, the units

are provided with two large wheels

and an ergonomically shaped

transport and protective handle.

This can easily be removed if

required.

The following must be observed

for unit transport:

1. Prior to a change of location

switch off the unit and discon-

nect the mains plug from the

socket-outlet.

2. Empty the condensate

container.

3. As long as there is still moisture

on the evaporator or water in

the condensate container, the

units must only be transported

in an upright position.

unit transport

Maintenance and Care

All moving parts are provided with

low-maintenance permanent lubri-

cation. The refrigeration system is

a hermetically sealed system and

must only be repaired by author-

ised specialist companies.

CAuTIOn

The mains cable must never

be used for pulling or fixing

purposes.

nOTE

Regular care and maintenance

is a basic precondition for a

long useful life and trouble-

free operation of the unit.

CAuTIOn

Before carrying out all work on

the units, the mains plug must

be removed from the socket-

outlet.

nOTE

Heavily clogged dust filters

must be replaced with

new ones.

Only original spare parts

must be used.

nOTE

Attention must be paid to

dripping condensate.

After switching off the unit,

the evaporator can continue to

defrost under the influence of

the ambient temperature.

CAuTIOn

Regularly check air inlet and

air outlet as well as the dust

filter for fouling.

Regularly check air inlet and

air outlet for fouling.

CAuTIOn

1