Trouble Shooting

The units were manufactured us-

ing the latest production methods

and tested repeatedly for perfect

function. If faults should still occur,

the unit must be checked against

the following list.

The unit does not start.

■

Check the operating switch set-

ting. The green pilot light must

illuminate

■

Check the supply connection

and local system fuse 230V/1~/

50Hz

■

Check the mains plug and mains

cable for damage

■

Check the level in the conden-

sate container and the container

for correct seating. (not for AMT

110-E)

■

Check the hygrostat setting (ac-

cessory).

The setting must be lower

than the relative humidity in

the room in which the unit is

installed

■

Check the adapter plug of the

hygrostat for damage and cor-

rect seating

The red (Fault) pilot light il-

luminates

■

The cooling circuit is overloaded

or overheated

■

Before restarting the unit, the

cause of the fault must first be

located.

To be noted is that the unit re-

starts automatically after cooling

down

The unit operates, but no

condensate forms

■

Check the room temperature.

The operating range of the unit

is between 3°C and 32°C

■

Check the humidity, min. 40%

RH necessary

■

Check the dust filter for clog-

ging and clean or replace as

necessary

■

Check the evaporator and

condenser fins for clogging and

clean if necessary

■

Check the evaporator for pos-

sible icing/frost formation.

If this is the case, the automatic

defrost function and tempera-

ture sensor must be checked

■

If the unit does not operate cor-

rectly despite the checks carried

out, an authorised specialist

company should be notified

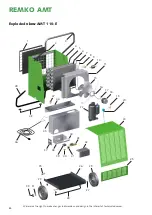

Cleaning the units

For cleaning the interior of the unit

and to gain access to the electri-

cal components, it is necessary to

open the unit housing.

1. Remove the two fixing screws

[B].

2. Lift the housing part and hang

out the front tabs.

3. Clean the condenser fins either

by blowing out, suction or with

a soft brush.

4. Clean the evaporator fins, e.g.

with a luke-warm soap solution

or similar.

5. Do not use a direct water jet.

6. Rinse with clean water to re-

move adhering soap residues.

7. Clean the inner surfaces of the

unit and fan impeller.

8. Clean the condensate trap and

connection.

9. After cleaning, the unit must be

dried.

Pay special attention to the

electrical components!

10. Refit all removed parts correctly

in reverse order.

11. Carry out a functional check

and safety test on the unit.

nOTE

Particular care must be taken

when cleaning the exchanger

as the fine aluminium fins bend

very easily.

CAuTIOn

Only specially authorised

firms may carry out work on

the refrigeration system and

electrical equipment.

nOTE

Adjustment and maintenance

tasks may be performed only

by authorised expert

personnel!

CAuTIOn

After completing all work on

the units, an electrical safety

test must be carried out in

accordance with VDE 0701.

B

B

1

REMKO AMT