Heat of condensation

The energy transferred from

the condenser to the air is

composed of:

1. Heat energy extracted from the

evaporator.

2. Electrical drive power.

3. The heat of condensation re-

leased through the condensation

of water vapour.

For the change from a liquid to

a gaseous state, energy is neces-

sary. This energy is termed heat of

evaporation. It does not cause any

rise of temperature, it is only nec-

essary for the change from a liquid

to a gaseous state. Vice versa,

energy is released during the liq-

uefaction of gas, which is termed

heat of condensation.

The amount of heat of evaporation

and condensation is the same.

For water, this is:

2250 kJ/kg (.18 kJ = 1kcal)

This shows that a relatively large

amount of energy is released

through the condensation of water

vapour.

If the moisture to be condensed is

not introduced through evapora-

tion in the room itself, but from

outside, e.g. via ventilation, the

heat of condensation released in

the process contributes towards

room heating. In drying processes,

the heat energy is recirculated,

which is consumed during evapo-

ration and released during con-

densation. The supplied air during

dehumidification creates a large

amount of heat energy, which is

expressed as a rise of temperature.

The time necessary for drying

normally does not depend only on

the unit capacity, but is rather de-

termined by the rate at which the

material or parts of the building

release their moisture.

Safety Instructions

The units were subjected to ex-

tensive material, functional and

quality inspections and tests prior

to delivery.

The unit can however constitute

a hazard if used improperly by

untrained persons or not for the

intended purpose.

The following information must be

observed:

■

The units must not be installed

or operated in locations subject

to explosion hazards

■

The units must not be installed

and operated in oil, sulphur,

chlorine or salt containing at-

mospheres

■

The units must be installed up-

right and stable

■

The units must not be subjected

to a direct jet of water

■

The air inlet and outlet must

always be kept free

■

The intake guard grilles must

always be free of dirt and loose

objects

■

The units must not be covered

during operation

■

Never insert objects in the unit

■

The units must not be trans-

ported during operation

■

The units must only be trans-

ported with drained condensate

containers and dry evaporator

■

All electric cables outside the

units must be protected against

damage (e.g. due to animals)

■

The condensate containers

must be drained prior to each

change of location

CAuTIOn

Only specially authorised firms

may carry out work on the re-

frigeration system and electri-

cal equipment.

CAuTIOn

Extension of the connecting

cable may only be carried

out by authorised electricians

taking into account the unit

power consumption, cable

length and local use.

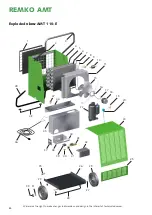

REMKO AMT