Device Description

The units are designed for univer-

sal and problem-free dehumidifica-

tion.

Owing to their compact size, they

are easy to transport and install.

The units operate according to the

condensation principle and feature

a hermetically sealed refrigeration

system, low noise and mainte-

nance circulating fan, operating

hour counter and connecting cable

with plug.

Fully automatic electronic con-

trol, condensate container with

integrated overflow protection

(not with AMT 110-E) as well as

connections for direct condensate

removal ensure trouble-free con-

tinuous use.

The units comply with the fun-

damental safety and health re-

quirements of the permanent EU

regulations.

The units are reliable and easy to

operate.

unit applications

The units are used wherever

dehumidication is necessary

and consequential damage (e.g.

through mould formation) is to be

prevented.

The units are also suitable for dry-

ing and dehumidification of:

■

New buildings, industrial build-

ings

■

Cellar rooms, storage rooms

■

Archives, laboratories

■

Weekend homes,

caravans

■

Bathrooms, washrooms and

changing rooms, etc.

As soon as the frost (ice) has de-

frosted and the temperature at the

sensor rises again, the unit switch-

es back to normal dehumidification

operation.

At a sufficiently high room tem-

perature, the gill surface is not cold

enough for the formation of frost

so that defrosting is unnecessary.

This makes dehumidifiers particu-

larly economical in operation.

At the condenser (heat exchang-

er), the cooled and dehumidified

air is reheated and blown back into

the room via the air outlet.

The conditioned, drier and heated

air mixes with the room air again.

Due to the constant circulation of

the room air through the unit, the

relative humidity in the room is

gradually reduced to the required

humidity (% R.H).

Depending on the room tem-

perature and humidity, only about

30-40% of electrical energy is

required depending on the unit

cooling capacity.

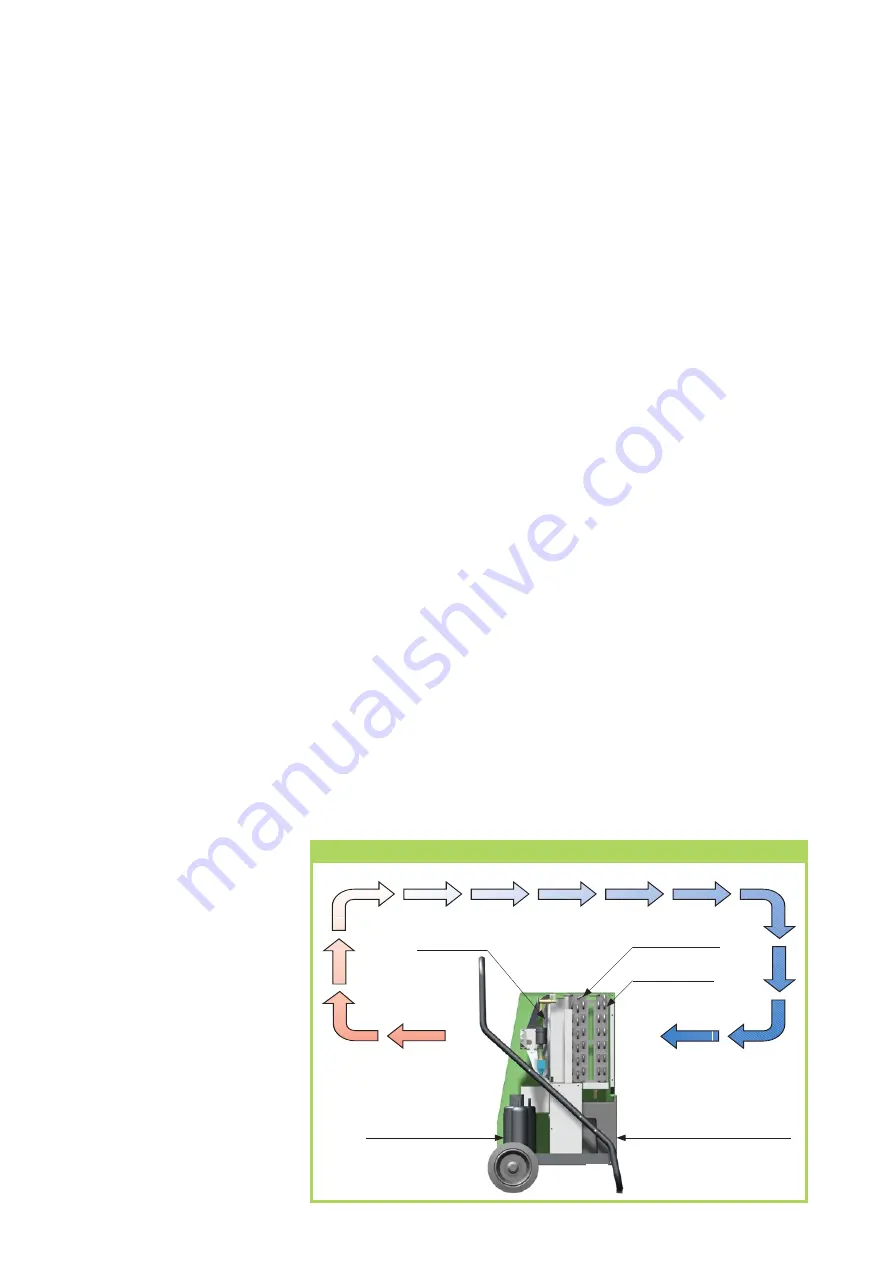

Sequence of functions

The electronic control is activated

when the unit is switched on.

The green pilot light in the switch

illuminates.

Owing to automatic pressure

equalisation, the units start with

a delay of about 10 seconds and

then operate in continuous duty.

The circulating fan sucks the moist

room air via the dust filter, evapo-

rator and downstream condenser.

At the cold evaporator, heat is

extracted from the room air and

cooled to below the dew point.

The water vapour contained in the

room air deposits as condensate or

frost on the evaporator fins.

When the temperature sensor

measures a specific minimum value

here, a timer is activated with a

delay of 30 minutes.

If during this time the evaporator

temperature does not rise again,

the cooling circuit is switched to

hot gas defrost after the time has

elapsed.

During the defrost phase, the cir-

culating fan is off.

Diagram of the mode of operation of a REMKO dehumidifier

Condensate con-

tainer

Moist room air

Dehumidified

Room air

Compressor

Condenser

Evaporator

Fan

8

REMKO AMT