17

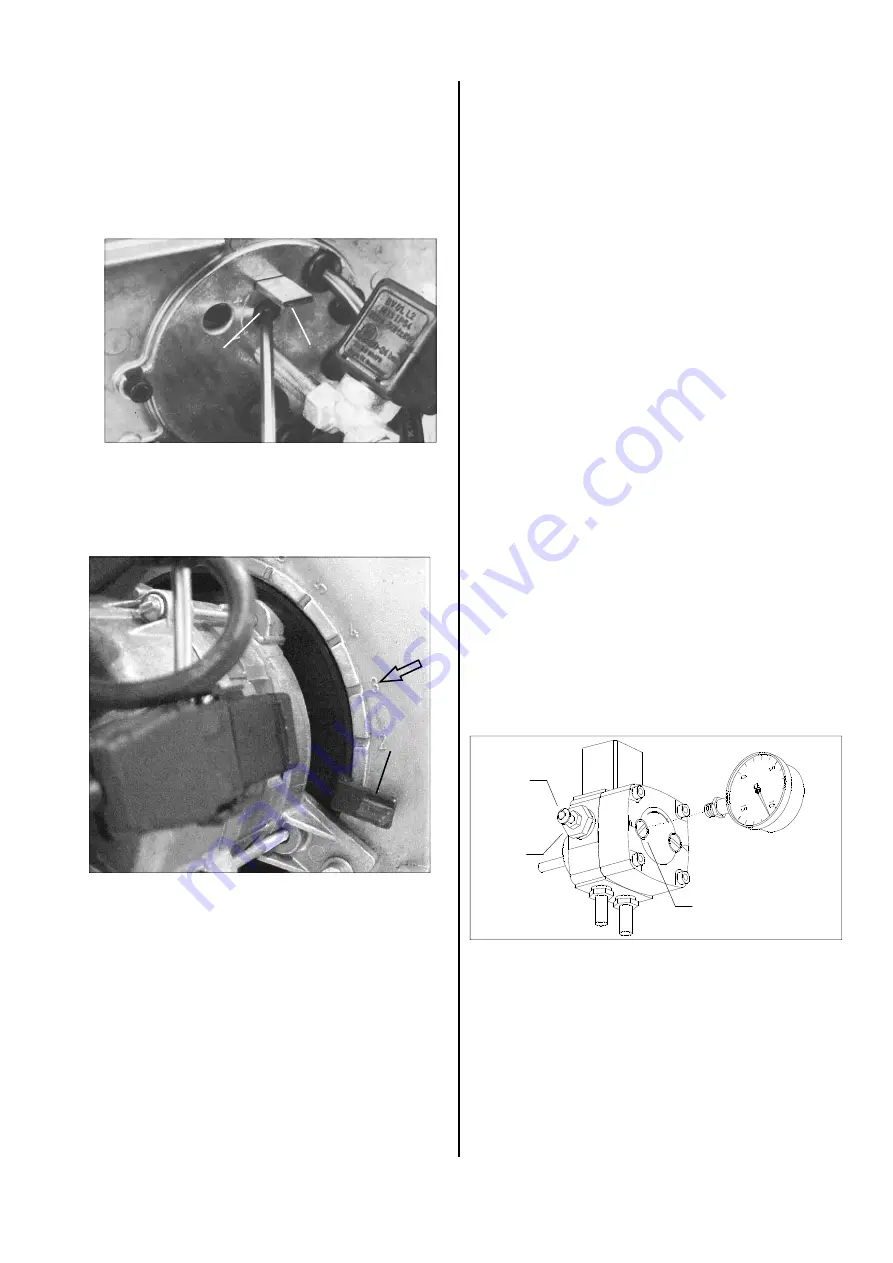

Secondary air setting (nozzle stock)

1. Set the nozzle stock (2) to the approx. 1.5 marking us-

ing the adjusting screw (1).

2

1

Adjusting the air inlet nozzle

1. Lock the adjust lever (3) of the air inlet nozzle in the

locking position (3) (see arrow).

3

Important information

◊

All specifications only serve as presettings and must

be readjusted or adapted according to the local con-

ditions during the exhaust emission analysis. The

settings can be made only if the chimney has been

properly installed!

◊

On principle, the equipment must be operated at the

nominal load.

◊

To guarantee the optimum function of the burner,

please note that annual maintenance must be per-

formed according to DIN 4755. For this purpose, you

should conclude a maintenance contract.

1. Remove the stopper on the "P" measuring connec-

tion and mount the oil manometer (seal!).

2. Open all oil shut-off fittings.

3. Switch on the burner using the operating switch.

4. Set the required oil pressure via the adjusting screw

(4) after loosening the counter nut (5).

Clockwise:

Increase pressure

Counterclockwise:

Reduce pressure

5. After making the pressure setting, secure the adjust-

ing screw using the counter nut (5).

Measuring the combustion gases

Every stationary combustion plant must be checked by

measuring the exhaust emission values according to

the first Bundesimmissionsschutzverordnung

(1.BImSchV) (German Air Pollution Act).

The owner is obliged to have the combustion plant

monitored by measurements performed by the local

chimney sweep up to four weeks after commissioning.

In addition, according to §§ 9 and 15 of 1. BImSchV, the

emission values must be checked annually by the local

chimney sweep (oil derivatives, soot, exhaust emis-

sions).

Setting the pump pressure

For initial burner operation and after each time the

burner is serviced, the oil pressure must be adjusted or

checked.

Never operate the pump without oil!

P

4

5

6. Switch on the unit using the operating switch.

7. Dismantle the oil manometer and replace the stop-

per (seal!).

Additional pump information

◊

Perfect fuel quality is absolutely necessary for the lu-

brication of the pump gear.

Never suction up water residue or fine dust that

tends to harden (such as cement).

◊

Never let the unit run with a dry pump for a longer

period of time.

Summary of Contents for CLK 20

Page 2: ......