6

Information on the safety devices

The safety devices are equipped with a sensor monitor-

ing feature and are resistant to cold down to -20°C . Be-

low -20°C, it switches off; when the temperature ri ses

above this temperature, it switches on again.

When the sensor or capillary tube is damaged or when

an excess temperature of approximately 220°C is

reached, the filling medium is emptied and the safety de-

vice switches off. The controller is no longer operable

and must be replaced.

If it is necessary to replace the STB, only the original

REMKO spare part should be used.

◊

Make sure to install and mount the device carefully.

◊

Do not bend the capillary tubes in the direct vicinity

of solder points.

◊

When installing the capillary tubes, be careful not to

damage or bend them too sharply.

◊

The sensors may only be mounted in the mounting

strap.

◊

The sensors must always be free of dust and dirt.

Installation Regulations

When the equipment is in use, the safety guidelines of

the employers' liability insurance associations, the re-

spective country construction ordinances, and the burn-

ing appliance regulations basically apply.

◊

Avoid underpressure or overpressure in mounting

rooms since these states always lead to combus-

tion-technical problems.

◊

Make sure the fresh air supply has been adapted to

the respective fan output (see model plate).

The forced-air oil burner must be equipped with a

separate combustion air supply if necessary.

Installation in closed, well-ventilated rooms without

a chimney connection

◊

The equipment may only be operated when the mini-

mum amount of air required for combustion accord-

ing to § 38 Sect. 4 (page 5) is supplied.

◊

A safe exhaust of the waste gases is to be ensured

to exclude an inadmissible pollution of the room air.

Fresh air is supplied from below.

Waste gases are expelled upwards.

Outdoor installation

◊

Due to the operation of the equipment, no dangers

or unreasonable nuisances may arise.

◊

The equipment operator must guarantee that unau-

thorised persons cannot manipulate the equipment

or the energy supply.

◊

Because rain and snow can be pulled in through the

supply air fan, a suitable protective covering should be

used.

Heating rooms

◊

The equipment may be used for room heating only

with a room thermostat (accessory).

◊

The supply of the fresh air required for proper com-

bustion must be guaranteed.

Safety distances

◊

To guarantee safe equipment operation and mainte-

nance, a safety distance of 1.5 metres around the

device must be observed.

◊

The floor and ceiling must be fire-resistant.

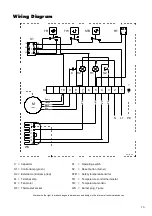

Electrical connection

◊

The equipment is operated at 1~ 230 V/50 Hz.

◊

The electrical connection of the equipment must be

performed at a certain supply point with an earth-

leakage circuit breaker according to VDE 0100 § 55.

◊

Suitable cable extensions may be used only when

unrolled.

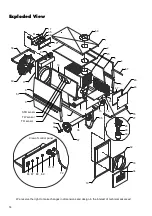

Safety Devices

The equipment has the following safety or monitoring

devices:

◊

Temperature control thermostat (TR)

◊

Temperature monitor (TW)

◊

Safety temperature limiter (STB)

Temperature control thermostat (TR)

The temperature control thermostat switches the circu-

lating fan on and off. The switching point is set in the

switch box using the "Scale 21 – 60" controller.

Setpoint approx. 35 – 40°C.

Temperature monitor (TW)

In heating mode, the temperature monitor limits both

the temperature of the unit and of the air being blown

out. The switching point is set in the switch box using

the "Scale 34 – 110" controller.

Setpoint approx. 80 – 85 °C.

Safety temperature limiter (STB)

The STB controls the temperature monitor. The switching

point has a permanent setting.

The burner is prevented from being restarted if the STB

is activated.

After the cover next to the control panel is removed, the

reset button must be pressed from the outside.

After the STB has been reset, the cover must be re-

mounted.

Before an STB reset, check the operating conditions

to ensure that the STB temperature is not exceeded

again.

Summary of Contents for CLK 20

Page 2: ......