7

1. Switch the operating

switch to the „0“

position (off).

2. In case of longer

downtimes,

disconnect the

unit from the

power mains.

Heating with room thermos-

tat

(accessory)

The appliances operate fully auto-

matically depending on the room

temperature.

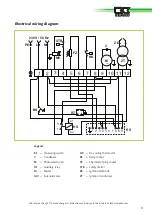

1. Disconnect the

jumper plug 2.

2. Connect the plug 3

of the room thermostat 4 toge-

ther with the thermostat socket

1 of the device.

3. Place the room thermostat (4)

at a suitable position in the

room.

The thermostat sensor may not

be in the path of direct hot air

flow and should not be placed

directly on a cold foundation.

4. Adjust the desired temperature

on the room thermostat.

5. Switch the

operating switch to the

„I“ position (on).

In case heating is needed, the unit

now switches on automatically and

then off when the desired room

temperature is reached.

Shutdown

CAUTION

Never interrupt the mains

connection before the entire

cool-down phase comes to

an end.

No warranty claims exist for

damage to the unit due to

overheating!

1

3

Notices regarding the safety

cut-off of the unit

The unit fuel supply takes place in

a single line system.

In this regard, the fuel supply to

the nozzle can be interrupted by

blowing air during the initial start-

up or after the fuel tank has been

completely emptied.

The automatic burner relay of the

appliances shut down due to mal-

function in this case.

This shutdown due to malfunction

is indicated by the red pilot lamp

on the control panel.

Reset the automatic burner relay

by pushing this red pilot lamp.

If the appliance does not start after

several start attempts,

read the

„Trouble Shooting“

section

Refill fuel if necessary

Never (except in emergency

situations) interrupt the mains

connection before the entire

cool-down phase comes to

an end.

4

The automatic burner relay can

get unlocked after a waiting

periode of 60 sec., only.

NOTE

In case of longer downtimes or

storage of the unit, always fill

the fuel tank with heating oil

or diesel fuel.

NOTE

☞

NOTE

The supply air fan runs to cool

off the combustion chamber

further and switches off later

on its own. The fan may run

several times until it switches

off permanently!

NOTE