5

Water vapour condensation

The maximum possible amount of water vapour

that

can be absorbed becomes higher when the air is

heat-

ed

, but the water vapour

content remains unchanged

and consequently the relative air humidity is reduced.

However, when the air is

cooled,

the maximum possi-

ble amount of water vapour that can be absorbed is

continuously reduced although the water vapour quanti-

ty contained in the air remains unchanged and conse-

quently the relative air humidity rises.

When the air is further cooled, the absorption capacity

with respect to the maximum amount of water vapour

possible is continuously reduced until it is equivalent to

the water vapour content. This is the dew point temper-

ature.

If the air is cooled below the dew point, the water va-

pour content will be higher than the maximum amount

of water vapour possible.

W ater v a po ur is ex p e l l ed .

It condenses, is converted into water and thus extracted

from the air.

Steamed up window panes in winter or

steamed up bottles containing cold drinks

are typical examples of condensation.

The higher the relative air humidity is, the

higher the dew point temperature is and con-

sequently the easier it is for the tempera-

tures to fall below the dew point.

The resulting condensa-

tion is collected in the de-

vice and drained.

Condensation heat

The energy transferred from the condenser to the air

consists of:

◊

The heat that was previously extracted in the evapo-

rator.

◊

The electric operating power.

◊

The condensation heat released by liquefying water

vapour.

When the liquid is converted into a gaseous state, ener-

gy must flow back. This energy is called evaporation

heat. It does not cause the temperature to rise but is

used for the conversion from the liquid to the gaseous

state. Conversely, energy is released when gas is lique-

fied, and this energy is called condensation heat.

The energy produced from evaporation and condensa-

tion heat is identical.

For water this is 2250 kJ / kg ( 4.18 kJ = 1kcal )

This shows that a relatively high amount of energy is re-

leased through water vapour condensation.

If the humidity to be condensed is not generated by

evaporation within the room, but supplied from the out-

side, e.g. by ventilation, the condensation heat released

thereby contributes to heating the room.

When materials or rooms are to be dried, the heat ener-

gy flows in a cycle, i.e. it is consumed during evapora-

tion

and

released

during

condensation.

A larger amount of heat energy is generated when sup-

plied air is dehumidified which is expressed as a rise in

temperature.

Generally, the time needed for drying does not depend

on the unit capacity, but is determined by the speed at

which the material or the parts of the building release

the moisture contained in them.

The air current is cooled on its way through/via the

evaporator until its temperature falls below the dew

point. The water vapour condenses, is collected in a

condensation tray and drained.

Drying materials

Building materials/buildings can absorb considerable

amounts of water; e.g. bricks 90

-190 l/m³, heavy con-

crete 140-190 l/m³, calcareous sandstone 180-270 l/m³.

Damp materials such as brickwork dry as described be-

low:

◊

The moisture contained in the material

flows from the inside to the surface

◊

Evaporation takes place on the sur-

face = water vapour is absorbed by

the ambient air.

◊

The air augmented with water vapour continuously

circulates through the REMKO air dehumidifier. It is

dehumidified and leaves the unit in a slightly warm

state to absorb water vapour again.

◊

This allows the moisture contained in the material to

be continuously reduced; the material becomes dry.

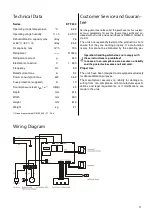

°C

30

25

20

15

% r.F.

100

90

80

70

60

50

40

30

20

10

+

+

-

condenser

evaporator

air-temperature

air direction

humidity

time