10

6. Do not clean with a water jet.

7. Clean evaporator lamellas with a lukewarm soap

solution.

8. Rinse with clean water to remove any remaining

soap residues.

9. Clean carefully the inner or internal surfaces of the

unit as well as the fan wing.

10. After that, dry with a clean cloth.

11. Mount all the parts in the reverse order.

12. Test the functions of the unit and perform an electri-

cal safety check!

In Case of Troubles

This unit has been designed based on state of the art

manufacturing methods and it has been tested repeat-

edly as to its perfect function.

However, if there are any operating troubles check the

unit according to the following listing:

The unit does not start:

◊

Control or check operating switch.

Green control lamp “operation” must lit.

◊

Check mains plugs.

◊

Check connection to the mains.

230V/1~ 50 Hz.

◊

Check mains fuse at user.

10 A resp. 16 A.

◊

Check filling level of the condensate tank and pour

out the condensate if necessary.

◊

Check the position of the condensate tank and the

cover lock have to be closed correctly.

◊

Check micro switch function.

◊

Control hygrostat setting (accessory). The set value

must be lower than the relative air humidity in the

room where the unit has been installed.

◊

Check intermediate plug of hygrostat to see whether

it has been damaged and whether it has been cor-

rectly plugged in.

Unit runs, but no condensate formation:

◊

Control ambient temperature. Unit operates within a

temperature range from 3° C to 32° C.

◊

Control air humidity.

Min. 40% relative humidity.

◊

Check hygrostat setting and set a lower value, if nec-

essary.

◊

Check whether dust filter is dirty, if so, clean it.

◊

Check whether the evaporator and condenser lamel-

las are dirty and clean them, if necessary.

◊

The evaporator is covered with ice. Check whether

automatic defrosting device operates correctly, or

check ambient temperature.

◊

Evaporator temperature is not lower than the room

temperature. Control automatic defrosting device

and compressor, respectively.

Out of the unit runs water / condensate:

◊

Check if the unit stands straightly.

◊

Check if the black filler cap is in the hose nipple of

the tank after the unit was work with hose connection

and/or after you have cleaned the unit.

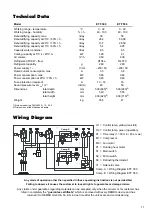

A

C

B

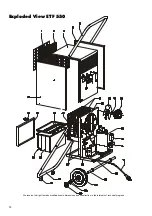

Condenser and Evaporator Cleaning

Dismount the casing of the unit before cleaning up the

condenser and evaporator. The following maintenance

have to be carried out only by an especially authorised

service company!

G

Sharp-edged lamellas survives injury-danger !

Clean the unit like the following description:

1. Remove the mains plug from the mains socket.

2. Remove the transport strap

A

and the

stand strap

B

.

3. Remove the side-plates

C

.

4. The lamellas of the condenser are either to be

blown out, to be vacuum-cleaned or to be cleaned

with a soft brush.

5. Please clean the condensator very carefully - the

fine aluminium lamellas can be easily deformed!

G

Make sure to remove the mains plug from the plug

socket before you carry out any of the described

measures or work!

G

If the unit does not work correctly in spite of the

controls or checks inform an authorised service

company.

Summary of Contents for ETF 300

Page 2: ......