6

Function

If you switch on the unit on the main switch, it will run in

a fully automatically operation.

Unit Description

These unit have been designed for automatic, universal

and problem-free air dehumidification.

Thanks to their compact dimensions they can be easily

transported and installed.

The unit work according to the condensation principle

and are equipped with a hermetically sealed refrigerat-

ing plant, a silent nearly maintenance-free ventilator as

well as with a connection cable with plug.

For an operation-control exists a green control-lamp

“operation” and a yellow control-lamp “condensate tank

full” on the control-panel. The correct time of operation

will record by a hour counter.

The fully automatic control, the water container incl. an

overflow-protection and a hose-nipple guaranteed a

continuously operation.

The unit correspond to the fundamental safety and

health requirements of the relevant EC regulations, they

operate safely and are easy to handle.

G

Any work regarding the refrigerating plant and its

electrical equipment is to be carried out exclu-

sively by especially authorised experts!

Safety Instructions

REMKO dehumidifiers will provide you with high utility

and long life thanks to our extensive material, function

and quality controls.

Dangers may arise nevertheless if the unit is used by

persons not familiar with its operation or if the unit is not

used for its intended purpose.

◊

Make sure to install and use the unit only in explo-

sion-proof rooms.

◊

Make sure not to install and use the unit in an atmos-

phere containing fuel, oil, sulphur and salt.

◊

Make sure to install the unit on a solid base and in a

vertical position.

◊

Make sure not to expose the unit to a direct water

jet.

◊

Make sure that the air can be freely sucked in and

blown off.

◊

Make sure that the suction side is always free from

dirt and loose objects.

◊

Never put objects into the unit.

◊

Do not cover the unit during operation.

◊

Make sure not to transport the unit during operation.

◊

Avoid strong vibrations on the unit as soon as there

is condensate in the condensate tank.

◊

Make sure to protect all electric cables outside the

unit from damage (e.g. by animals).

◊

Before installing connection cable extensions make

sure that they are suitable for the connected power,

cable length and the intended purpose.

◊

Make sure to empty the condensate tank before in-

stalling the unit in another place.

◊

Make sure to transport the unit only in a vertical posi-

tion.

◊

Damage on the compressor will be avoid by a wait-

ing period of at least 3 minutes before starting the

unit.

◊

Uses/operations other than that indicated in these

operating instructions are not allowed!

In the case of non-observation, any of our responsi-

bilities and guarantees will become void.

◊

The unit is to be used with the environmentally

friendly, ozone-neutral refrigerant R407C.

◊

The refrigerant/oil mixture in the unit is to be dis-

posed of correctly and in accordance with the legal

or local prescriptions.

Important Tip Regarding Recycling!

The

fan

sucks in the ambient air via the air filter, the

evaporator and the condenser placed behind the latter.

Heat is extracted from the ambient air at the cold

evaporator.

It cools down below the dew point, and the

water vapour contained in the air is deposited as con-

densate or hair frost on the evaporator lamellas. When

necessary the evaporator is defrosted with hot gas with

temperature control.

The dehumidified cooled down air is reheated at the

condenser

(heat exchanger), and then it is blown out

when it has reached a temperature of approx. 3 - 5 de-

grees above the ambient temperature.

The treated dry air is mixed with the ambient air.

Thanks to the continuous circulation of the ambient air

through the unit, the relative air humidity in the place of

installation is continuously reduced until it has reached

the desired value.

Schematic display of function

floater

condensate tank

ambient air

fan

compressor

dehumidified

ambient air

condenser

evaporator

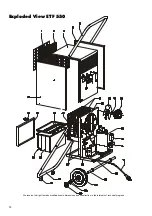

Summary of Contents for ETF 300

Page 2: ......