9

Discard the Unit

Prior to longer operating breaks or pauses:

1. Remove the mains plug from the plug socket (or

transitional socket).

2. Empty the condensate container and dry it with a

clean cloth.

3. Make sure that no condensate continues to drop or

drip!

4. Clean the dust filter according to the given instruc-

tions.

5. Protect the unit, possibly with a plastic cover, and

store it in a vertical position in a safe place.

Put the operating switch into “0” position.

Damage on the compressor will be avoid by

a waiting period of at least 3 minutes before

starting the unit.

Maintenance and Service

Regular care and the observation of a number of basic

rules will ensure the dehumidifier’s long life and reliable

operation.

The complete cooling system is hermetically sealed and

contains no user-serviceable parts. It may only be serv-

iced by authorised repair facilities.

All moving parts feature low-maintenance long-life lubri-

cation.

The unit should be inspected and cleaned thoroughly

after each long period of operation, at a minimum once

a year.

Please note the following points:

◊

Ensure that the interior and exterior of the unit re-

mains free of dust and other deposits.

◊

Clean the unit only with a dry or dampened cloth.

◊

Do not use a water jet.

◊

Do not use aggressive cleansers or cleaning prod-

ucts containing solvents.

◊

Regularly check the dust filter and the exhaust grille

for soiling and clean them as required.

◊

Replace the dust filter as required.

Dust Filter Cleaning

◊

Lift the air suction grille slightly and remove it pulling

towards and downwards.

◊

Then remove the dust filter.

◊

Slight o insignificant dirt is to be cleaned by blowing

out or vacuum-cleaning the dust filter carefully.

◊

If the dust filter is very dirty it is to be washed with a

lukewarm soap solution (max. 40° C) and then to be

rinsed with clear water.

◊

Make sure that the dust filter is completely dry and

undamaged before you reinstall it.

◊

In case of extreme dirt the dust filter is to be replace.

◊

Never use the unit without installed dust filter!

Working Range

Dehumidification performance depends exclusively

upon the design of the room, the room temperature, the

relative humidity and the correct observance of the

setup instructions.

The dehumidification performance increases with the

room temperature and relative humidity.

For a reliable

operation the following working-range is

valid:

◊

Room temperature between 6 °C and 32 °C

◊

Relative humidity between 40% and 100% r. h.

G

The proper functioning of the unit cannot be guar-

anteed at temperatures below 10 °C or a relative

humidity of less than 40% r. h.

G

Do not use the cable to pull the unit!

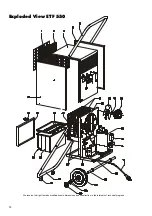

Transport Instructions

The unit is equipped with 2 wheels and an easily remov-

able transport handle to ensure safe transport.

1. Switch off the unit prior to changing its place and to

remove the mains plug from the mains socket.

2. After that empty the condensate container.

3. Make sure to transport and store the unit only in a

vertical position as long as there is still humidity at

the evaporator, in the condensate trap and in the

condensate container.

G

Works at refrigerating plant and at electrical equip-

ment is to be carried out only by an especially

authorised service company!

Summary of Contents for ETF 300

Page 2: ......