10

REMKO ETF 320

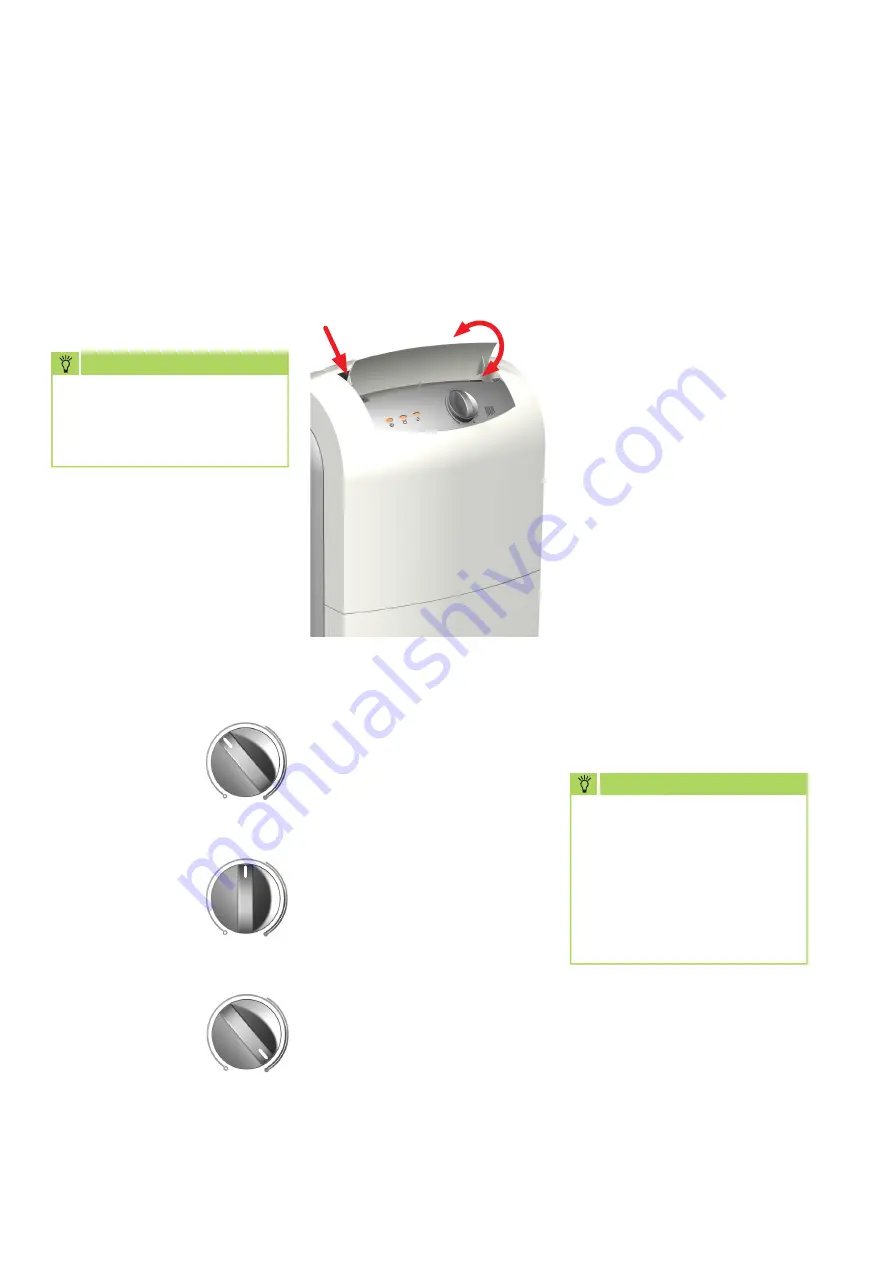

Adjusting the discharge

direction

The dehumidified room air is

discharged on the top of the unit.

The pivotable air flap [S] is used to

adjust the discharge direction.

Press the air flap’s rear surface [D]

to open it.

The front folds upwards. The air

direction can be adjusted infinitely.

The following notes must also be

observed in full:

■

If possible, open the air flap

completely to direct the air flow

upwards

■

Ensure that the air can

discharge without hindrances

This is the only way to

guarantee optimum unit

operation!

■

Ensure that sensitive objects

such as house plants are not

placed directly in the air flow

emerging from the unit

D

S

Automatic defrost system

The moisture contained in the

room air condenses when cooling

and coats the evaporator fins

with rime or ice depending on the

air temperature and the relative

humidity (% RH).

The automatic defrost system that

is integrated in the unit switches

the defrost cycle on if required.

The rime or ice that has

accumulated on the exchanger

surfaces is defrosted using heat gas

as required.

This defrosting method is

particularly fast and effective, and

guarantees high dehumidification

performance.

Dehumidification mode is only

paused for a short time during the

defrost phase.

The “Defrost mode” indicator light

indicates that the defrost cycle is

running.

NOTE

If the room temperature is

sufficiently high, the surface

of the fins will not be cold

enough for rime formation to

occur, rendering defrosting

unnecessary.

Therefore, the air dehumidifier

works economically.

Adjusting units/moisture

The unit’s dehumidification power

is entirely dependent on the

conditions inside the room, the

room temperature, the relative

humidity and observance of the

notes in the “Setting up”chapter.

The higher the room temperature

and relative air humidity,

the higher the dehumidification

power.

A relative humidity of around

45 to 60 % is sufficient in living

rooms. The air humidity should not

exceed 40 to 45 % in warehouses,

archives, etc.

Adjust the hygrostat

for the recommended

air humidity

in living rooms.

Approx. 50 %.

Adjust the hygrostat

for the recommended

air humidity

in archives.

Approx. 40 %.

Adjust the hygrostat

for the minimum

air humidity in the

installation room.

The units work in continuous

operation in this position!

NOTE

The maximum possible

dehumidification power is only

obtained when the air flap is

opened completely.

s

s

s